Chimney leaks in Minneapolis; Part One

Chimney leaks in Minneapolis are very, very common. Unlike many areas of the country we deal with the affects of ice and snow, in addition to the normal forces that affect chimney performance such as wind, rain and the sun. I will be writing a few posts about common chimney damage in the coming weeks. This post focuses on the top of the chimney, otherwise known as the ‘wash cap’.

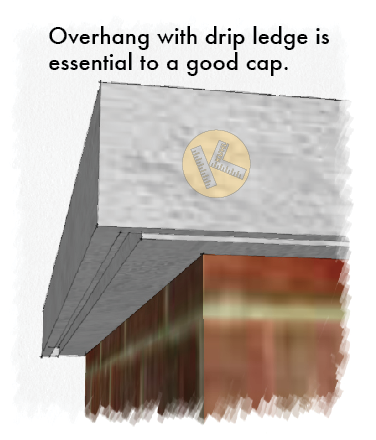

Below are two Kuhl drawings, one showing a poor, albeit super common chimney cap design in Minneapolis, the other, the proper design.

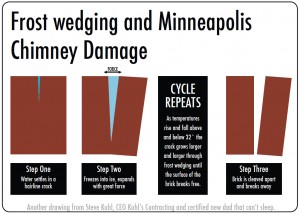

The same process that creates potholes on our Minnesota roads is acting on your masonry chimney. It’s true and the principle is quite simple. See my little diagram, right.

The easiest way to keep your brick or stone chimney in good condition is to keep water from working its’ way into the cracks that inevitably develop on the surface of your chimney. The majority of the chimneys I inspect that have damage have one major flaw in common. They lack an overhang to encourage water to say away from the column of the chimney. Just as homes typically have overhangs at the eaves so should chimneys.

Most of the masonry and stone chimneys we repair in the Minneapolis area receive a new wash cap, some brick resetting and general tuck pointing. Some chimneys have to be completely rebuilt. The main determining factor in how much damage we find is how long the homeowner has let water do its’ thing through the freeze-thaw cycle on their chimney.

Here is an example of a very common problem we find on Minneapolis chimneys. The masons who built the original chimney used mortar, not concrete, to hand-trowel the wash cap into shape. It lacks any overhang and has allowed water to find its’ way into the body of the chimney column over time. Through the freeze-thaw cycle that water has caused severe damage to the material below the cap. We replace about 150 bad wash caps a year for this very reason.