Case Studies

Click & Discover

What Really Kills Most Cedar Shake Roofs

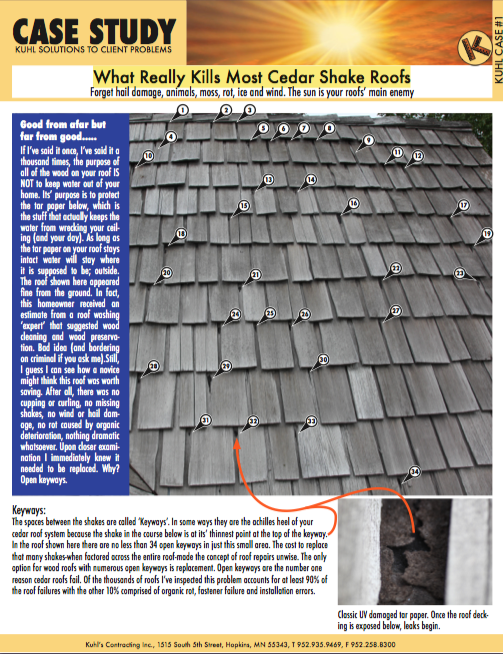

If I’ve said it once, I’ve said it a thousand times, the purpose of all of the wood on your roof IS NOT to keep water out of your home. Its’ purpose is to protect the tar paper below, which is the stuff that actually keeps the water from wrecking your ceil- ing (and your day). As long as the tar paper on your roof stays intact water will stay where it is supposed to be; outside. The roof shown here appeared fine from the ground. In fact, this homeowner received an estimate from a roof washing ‘expert’ that suggested wood cleaning and wood preserva- tion. Bad idea (and bordering on criminal if you ask me).Still, I guess I can see how a novice might think this roof was worth saving. After all, there was no cupping or curling, no missing shakes, no wind or hail dam- age, no rot caused by organic deterioration, nothing dramatic whatsoever. Upon closer exami- nation I immediately knew it needed to be replaced. Why? Open keyways.

Keyways:

The spaces between the shakes are called ‘Keyways’. In some ways they are the achilles heel of your cedar roof system because the shake in the course below is at its’ thinnest point at the top of the keyway. In the roof shown here there are no less than 34 open keyways in just this small area. The cost to replace that many shakes-when factored across the entire roof-made the concept of roof repairs unwise. The only option for wood roofs with numerous open keyways is replacement. Open keyways are the number one reason cedar roofs fail. Of the thousands of roofs I’ve inspected this problem accounts for at least 90% of the roof failures with the other 10% comprised of organic rot, fastener failure and installation errors.

Flat Roof In Minneapolis Leaked for Years and Copper Was the Answer

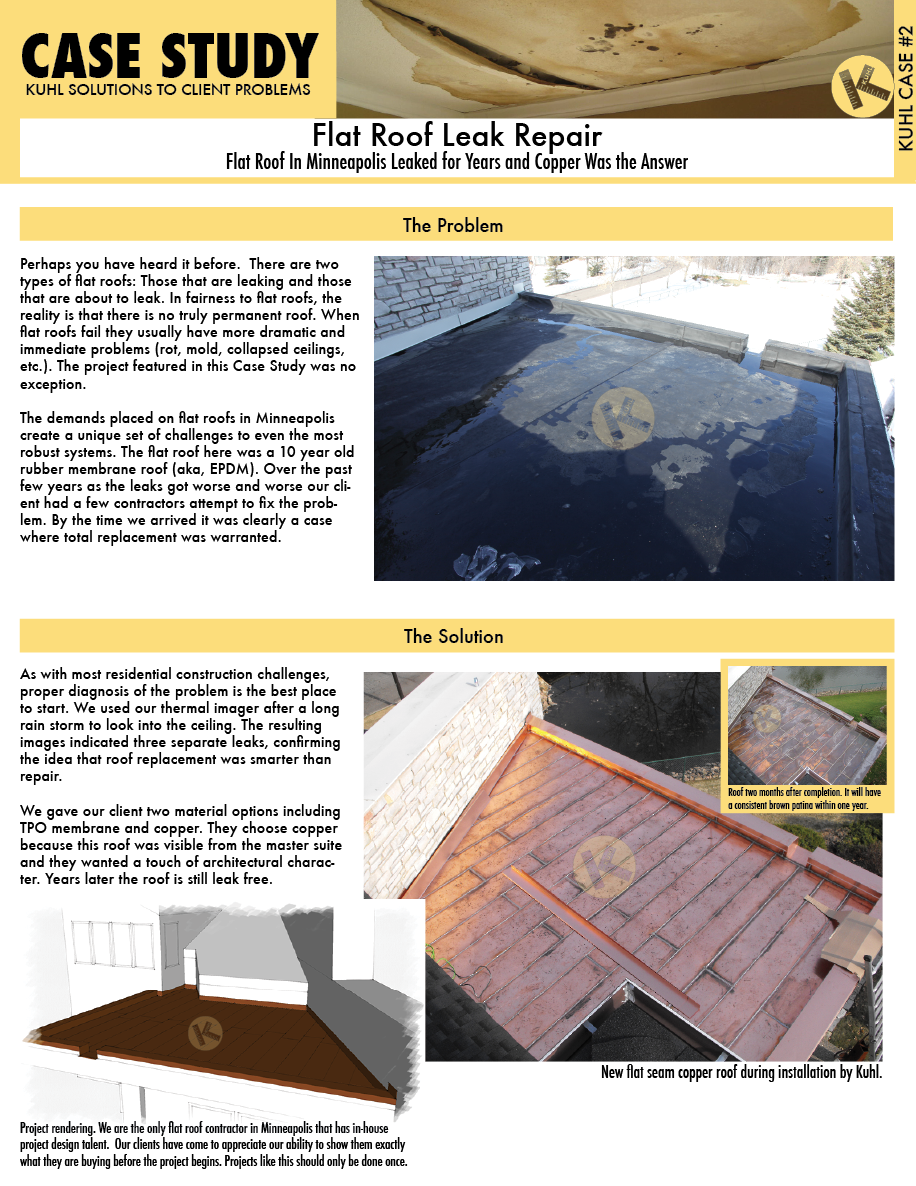

Perhaps you have heard it before. There are two types of flat roofs: Those that are leaking and those that are about to leak. In fairness to flat roofs, the reality is that there is no truly permanent roof. When flat roofs fail they usually have more dramatic and immediate problems (rot, mold, collapsed ceilings, etc.). The project featured in this Case Study was no exception.

The demands placed on flat roofs in Minneapolis create a unique set of challenges to even the most robust systems. The flat roof here was a 10 year old rubber membrane roof (aka, EPDM). Over the past few years as the leaks got worse and worse our cli- ent had a few contractors attempt to fix the prob- lem. By the time we arrived it was clearly a case where total replacement was warranted.

As with most residential construction challenges, proper diagnosis of the problem is the best place to start. We used our thermal imager after a long rain storm to look into the ceiling. The resulting images indicated three separate leaks, confirming the idea that roof replacement was smarter than repair.

We gave our client two material options including TPO membrane and copper. They choose copper because this roof was visible from the master suite and they wanted a touch of architectural charac- ter. Years later the roof is still leak free.

Minneapolis Cedar Roof Comparisons

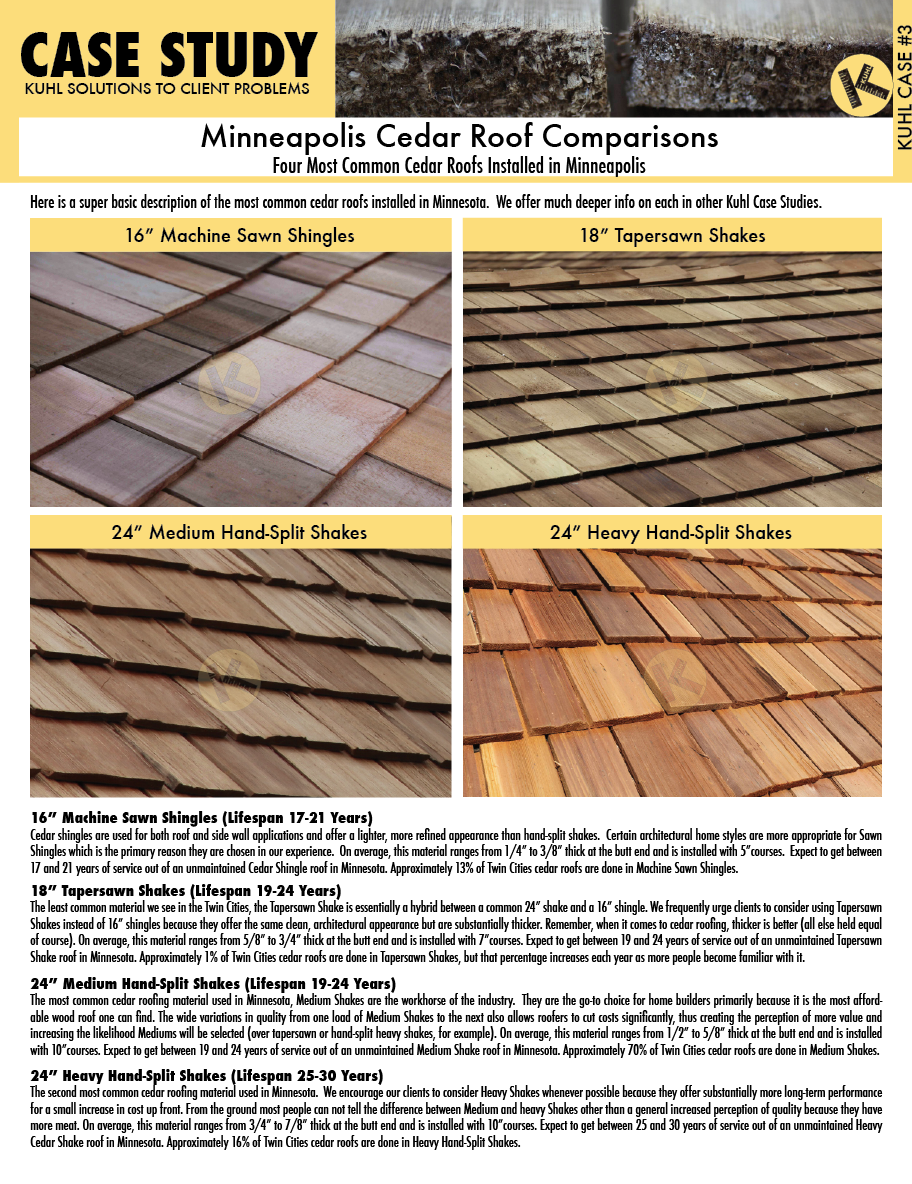

16” Machine Sawn Shingles (Lifespan 17-21 Years)

Cedar shingles are used for both roof and side wall applications and offer a lighter, more refined appearance than hand-split shakes. Certain architectural home styles are more appropriate for Sawn Shingles which is the primary reason they are chosen in our experience. On average, this material ranges from 1/4” to 3/8” thick at the butt end and is installed with 5”courses. Expect to get between 17 and 21 years of service out of an unmaintained Cedar Shingle roof in Minnesota. Approximately 13% of Twin Cities cedar roofs are done in Machine Sawn Shingles.

18” Tapersawn Shakes (Lifespan 19-24 Years)

The least common material we see in the Twin Cities, the Tapersawn Shake is essentially a hybrid between a common 24” shake and a 16” shingle. We frequently urge clients to consider using Tapersawn Shakes instead of 16” shingles because they offer the same clean, architectural appearance but are substantially thicker. Remember, when it comes to cedar roofing, thicker is better (all else held equal of course). On average, this material ranges from 5/8” to 3/4” thick at the butt end and is installed with 7”courses. Expect to get between 19 and 24 years of service out of an unmaintained Tapersawn Shake roof in Minnesota. Approximately 1% of Twin Cities cedar roofs are done in Tapersawn Shakes, but that percentage increases each year as more people become familiar with it.

24” Medium Hand-Split Shakes (Lifespan 19-24 Years)

The most common cedar roofing material used in Minnesota, Medium Shakes are the workhorse of the industry. They are the go-to choice for home builders primarily because it is the most afford- able wood roof one can find. The wide variations in quality from one load of Medium Shakes to the next also allows roofers to cut costs significantly, thus creating the perception of more value and increasing the likelihood Mediums will be selected (over tapersawn or hand-split heavy shakes, for example). On average, this material ranges from 1/2” to 5/8” thick at the butt end and is installed with 10”courses. Expect to get between 19 and 24 years of service out of an unmaintained Medium Shake roof in Minnesota. Approximately 70% of Twin Cities cedar roofs are done in Medium Shakes.

24” Heavy Hand-Split Shakes (Lifespan 25-30 Years)

The second most common cedar roofing material used in Minnesota. We encourage our clients to consider Heavy Shakes whenever possible because they offer substantially more long-term performance for a small increase in cost up front. From the ground most people can not tell the difference between Medium and heavy Shakes other than a general increased perception of quality because they have more meat. On average, this material ranges from 3/4” to 7/8” thick at the butt end and is installed with 10”courses. Expect to get between 25 and 30 years of service out of an unmaintained Heavy Cedar Shake roof in Minnesota. Approximately 16% of Twin Cities cedar roofs are done in Heavy Hand-Split Shakes.

How To Identify Good Cedar Roofing

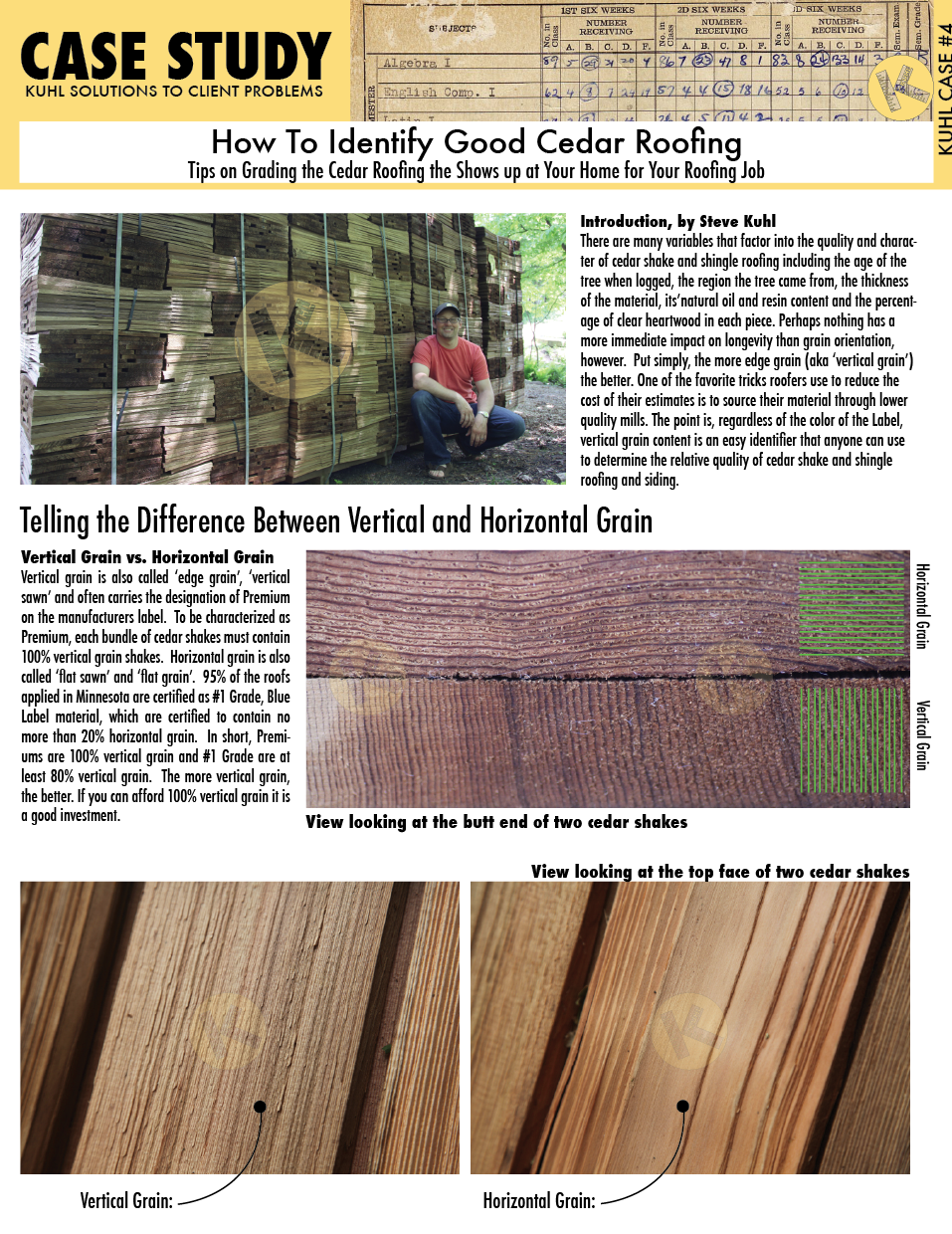

There are many variables that factor into the quality and charac- ter of cedar shake and shingle roofing including the age of the tree when logged, the region the tree came from, the thickness of the material, its’natural oil and resin content and the percent- age of clear heartwood in each piece. Perhaps nothing has a more immediate impact on longevity than grain orientation, however. Put simply, the more edge grain (aka ‘vertical grain’) the better. One of the favorite tricks roofers use to reduce the cost of their estimates is to source their material through lower quality mills. The point is, regardless of the color of the Label, vertical grain content is an easy identifier that anyone can use to determine the relative quality of cedar shake and shingle roofing and siding.

Telling the Difference Between Vertical and Horizontal Grain

Vertical grain is also called ‘edge grain’, ‘vertical sawn’ and often carries the designation of Premium on the manufacturers label. To be characterized as Premium, each bundle of cedar shakes must contain 100% vertical grain shakes. Horizontal grain is also called ‘flat sawn’ and ‘flat grain’. 95% of the roofs applied in Minnesota are certified as #1 Grade, Blue Label material, which are certified to contain no more than 20% horizontal grain. In short, Premi- ums are 100% vertical grain and #1 Grade are at least 80% vertical grain. The more vertical grain, the better. If you can afford 100% vertical grain it is a good investment.

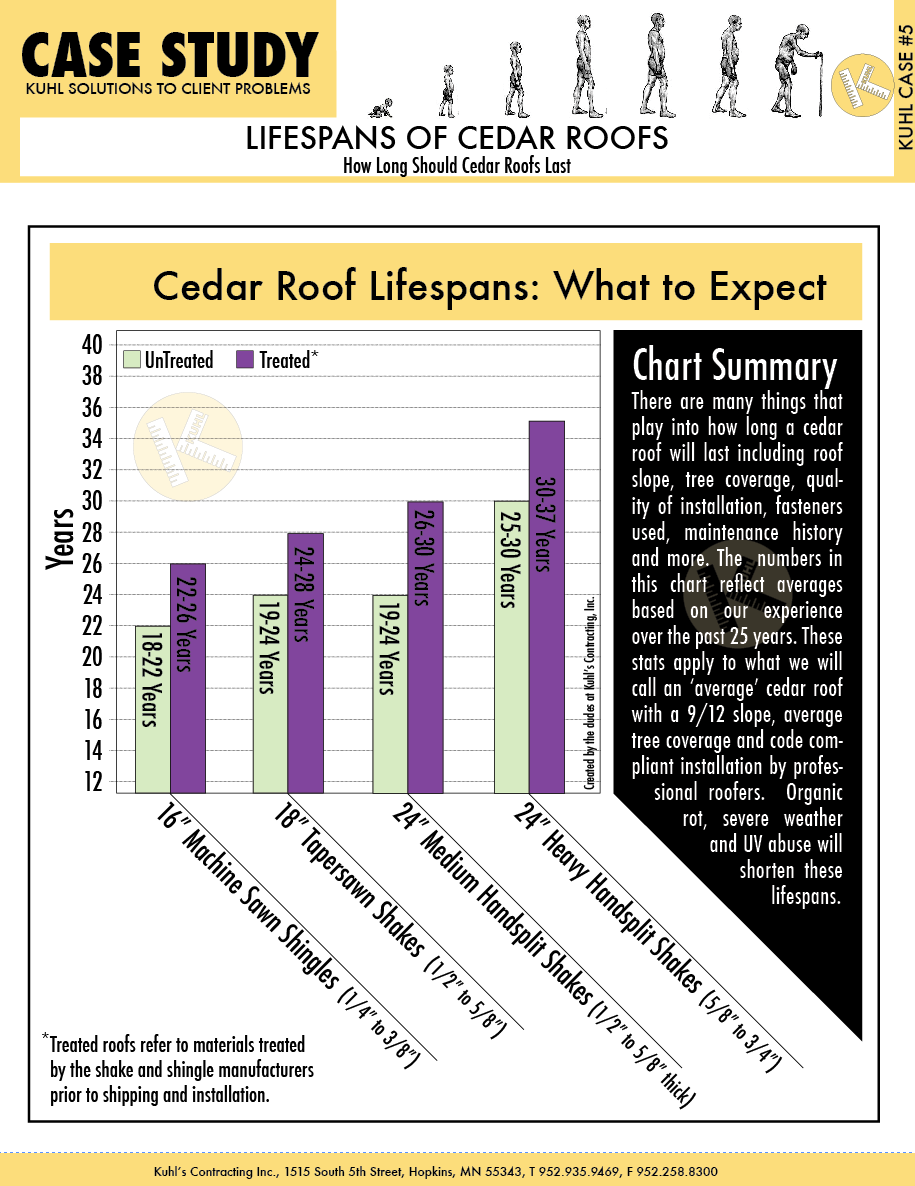

Lifespans of Cedar Roofs

There are many things that play into how long a cedar roof will last including roof slope, tree coverage, qual- ity of installation, fasteners used, maintenance history and more. The numbers in this chart reflect averages based on our experience over the past 25 years. These stats apply to what we will call an ‘average’ cedar roof with a 9/12 slope, average tree coverage and code com- pliant installation by professional roofers. Organic rot, severe weather and UV abuse will shorten these lifespans.

Solving Ice Dams In Minneapolis

ICE DAM SCIENCE

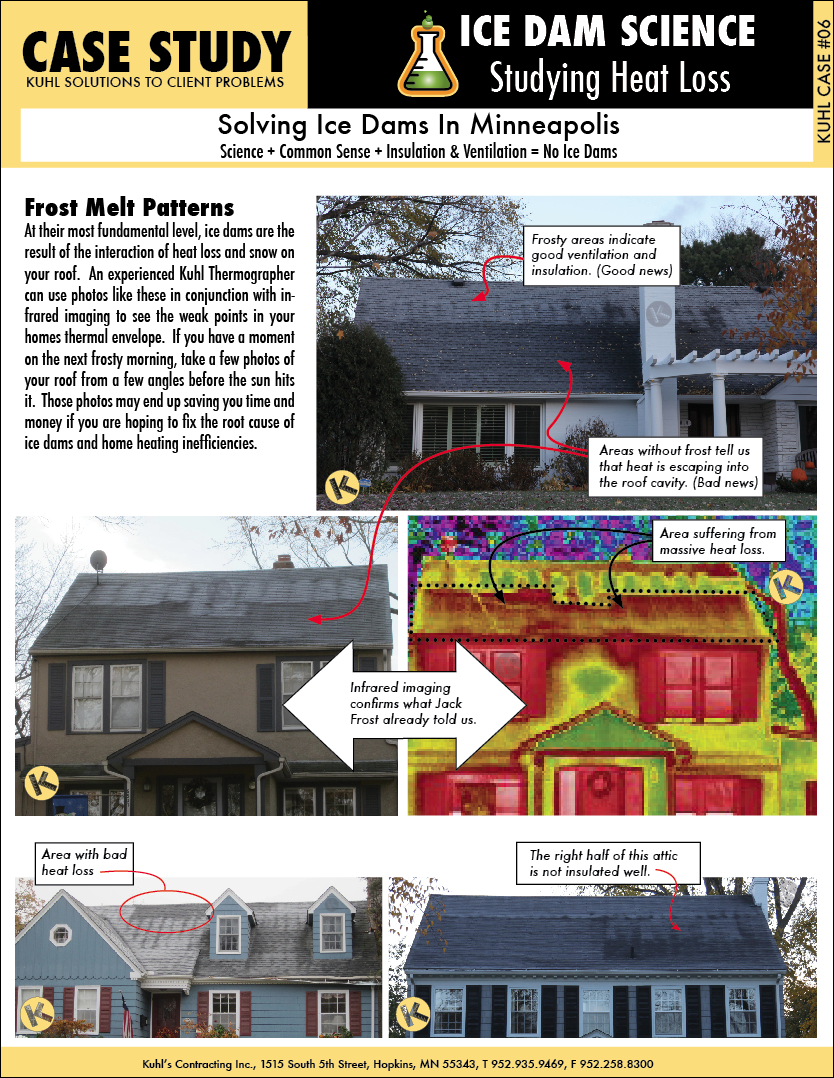

Frost Melt Patterns

At their most fundamental level, ice dams are the result of the interaction of heat loss and snow on your roof. An experienced Kuhl Thermographer can use photos like these in conjunction with in- frared imaging to see the weak points in your homes thermal envelope. If you have a moment on the next frosty morning, take a few photos of your roof from a few angles before the sun hits it. Those photos may end up saving you time and money if you are hoping to fix the root cause of ice dams and home heating inefficiencies.

Pressure Washing Damage on Cedar Roof

Pressure Washing Damage on Cedar Roof

WHY EQUIPMENT MATTERS

If your roof is in good enough condition to wash, con- gratulations. You have the opportunity to add years to its remaining life through occasional maintenance. But it is important to understand that a cedar roof should only be washed using specialized equipment. Standard pres- sure washers, like the one pictured to the right, will do a good deal of damage to a cedar roof regardless of the user. That damage will most likely not be visible from the ground because it is a matter of hundreds of an inch. In fact, consumer-grade pressure washers will remove between five and eight times the amount of wood from your cedar roof than professional equipment. If you have ever seen a cedar deck that looks furry and splin- tery after washing you know what we are talking about.

Kuhl only uses high volume, low-pressure equipment to wash cedar roofs. Our trailer mounted washing unit is custom built for washing cedar roofs and cost us $25,000, not including Steve’s free labor to weld it all together. There are only a couple of wood restoration firms in the country that use this specialty equipment. Where the standard consumer-grade machine will push 3-4 gallons per minute through the wand, ours pushes 12! This is why we often refer to our process as power rinsing, not power washing.

Why should you care? Because regular pressure washers–the kind used by painters, handymen and some of our competitors–are an entirely different machine. Such units should never be used on a cedar roof as they operate at inappropriate water volume to pres- sure ratios, resulting in significant wood loss. (See the photo in the header of this Case Study. Right half shows major wood loss.)

Companies that don’t invest in industrial equipment do so for one reason; it is much cheaper to use a cheap machine than an industrial unit. From the ground the results look about the same to you. The discoloration on your roof is gone, the roof looks fresh and clean again. But upon close inspection you will see that those machines have removed a lot of wood. Not good. Regard- less of the appearance

from the ground, using a typical pressure washer on a cedar roof will take years off its existing lifespan even if wood cleaners and/or brighteners are used. Ultimately, wood loss in the keyways of your roof is one of the pri- mary reasons your roof will fail in the future.

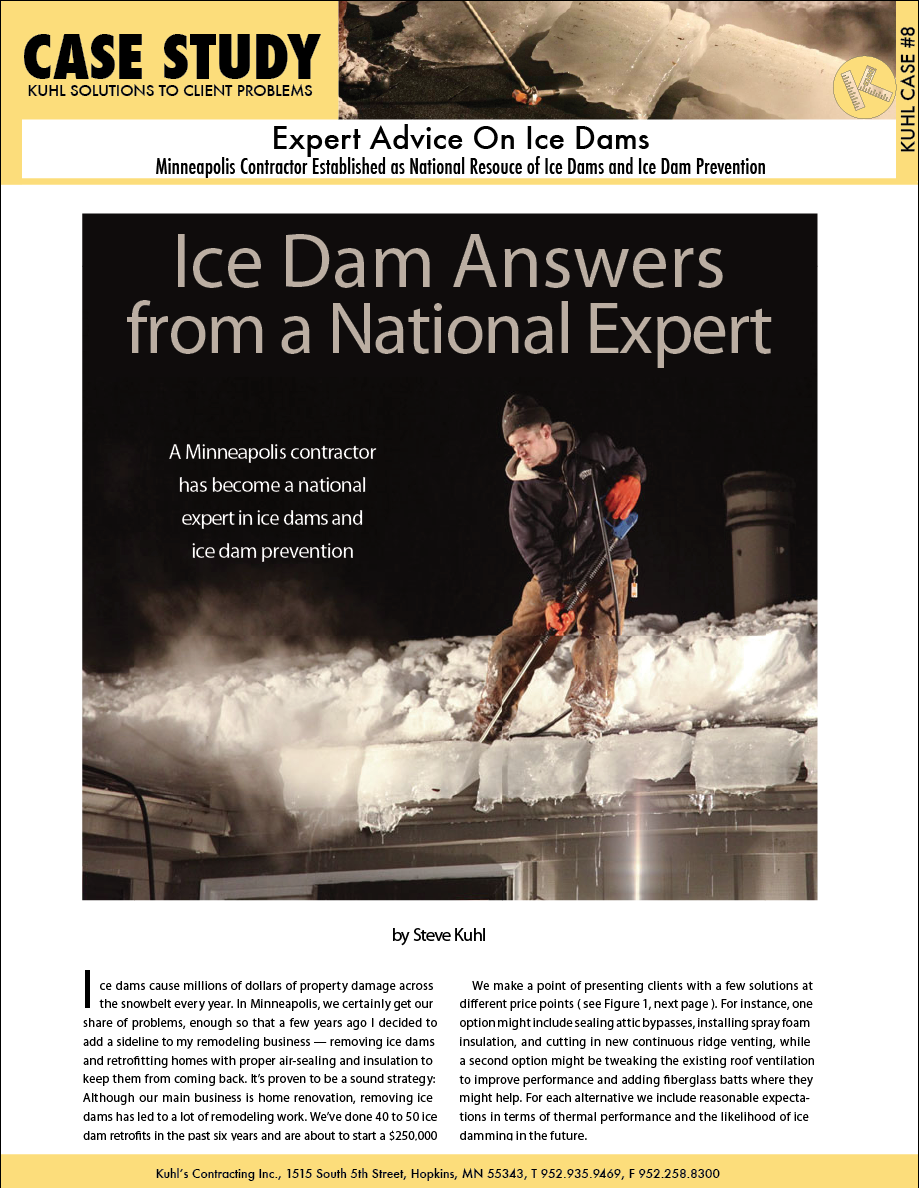

National Ice Dam Expert Grew Up In Minneapolis, Minnesota. Go figure.

Ice Dam prevention

No one knows more about ice dam removal and ice dam prevention than The Ice Dam Company. We have been removing snow and ice from homes and businesses for over twenty years. There’s a reason why Kare 11, KSTP, Fox 9, WCCO and the Star Tribune call on us for our expertise and ice dam tips every year they develop. It’s that we know what we are doing and we are honest about how we do it.

Six Examples of How the Cheapest Company Costs the Most

Low Bidding Minneapolis Contractor Wins Again

Six Examples of How the Cheapest Company Costs the Most

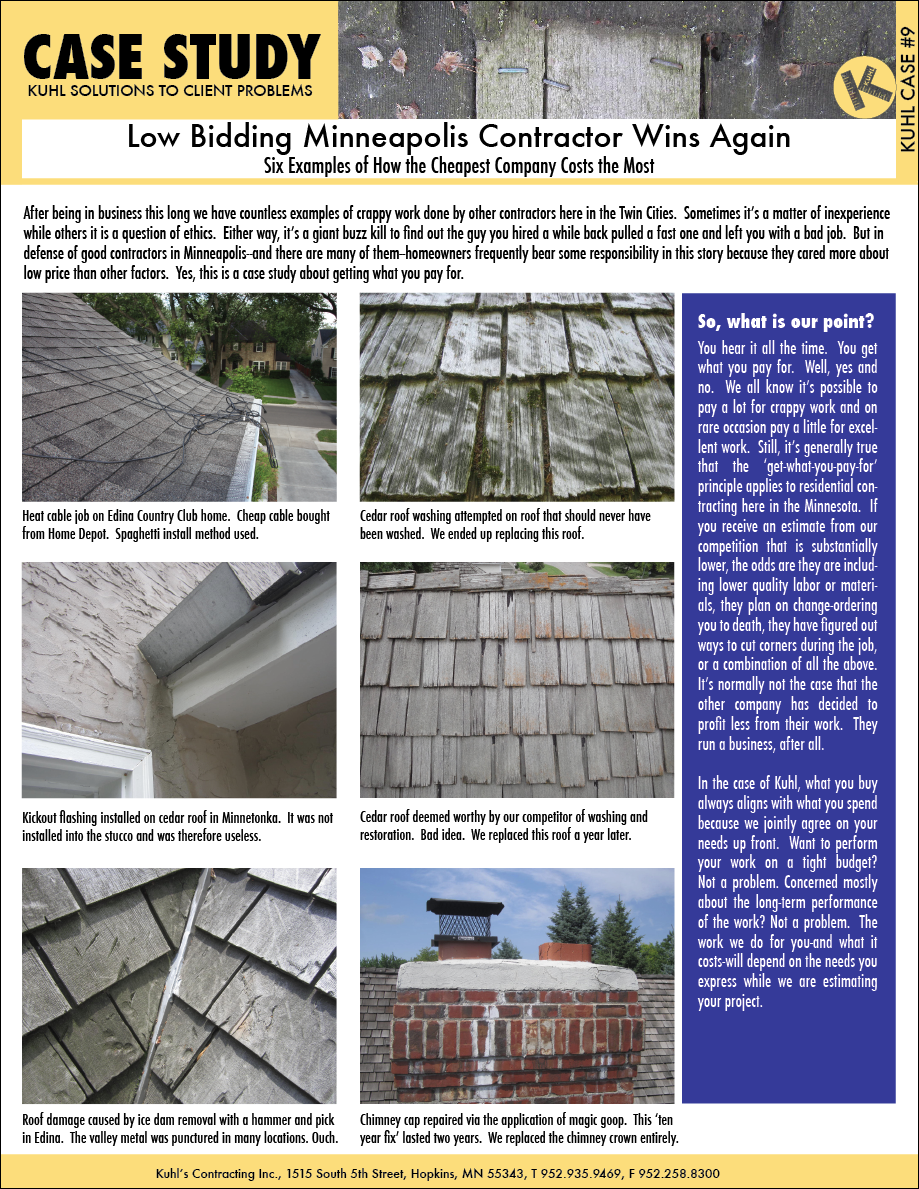

After being in business this long we have countless examples of crappy work done by other contractors here in the Twin Cities. Sometimes it’s a matter of inexperience while others it is a question of ethics. Either way, it’s a giant buzz kill to find out the guy you hired a while back pulled a fast one and left you with a bad job. But in defense of good contractors in Minneapolis–and there are many of them–homeowners frequently bear some responsibility in this story because they cared more about low price than other factors. Yes, this is a case study about getting what you pay for.

So, what is our point?

You hear it all the time. You get what you pay for. Well, yes and no. We all know it’s possible to pay a lot for crappy work and on rare occasion pay a little for excel- lent work. Still, it’s generally true that the ‘get-what-you-pay-for’ principle applies to residential con- tracting here in the Minnesota. If you receive an estimate from our competition that is substantially lower, the odds are they are includ- ing lower quality labor or materi- als, they plan on change-ordering you to death, they have figured out ways to cut corners during the job, or a combination of all the above. It’s normally not the case that the other company has decided to profit less from their work. They run a business, after all.

In the case of Kuhl, what you buy always aligns with what you spend because we jointly agree on your needs up front. Want to perform your work on a tight budget? Not a problem. Concerned mostly about the long-term performance of the work? Not a problem. The work we do for you-and what it costs-will depend on the needs you express while we are estimating your project.

Edina Roofing Contractor Invents Permanent Squirrel Damage Solution

Permanent Squirrel Damage Solution

How to Replace a Tasty Lead Cap with Galvanized Steel

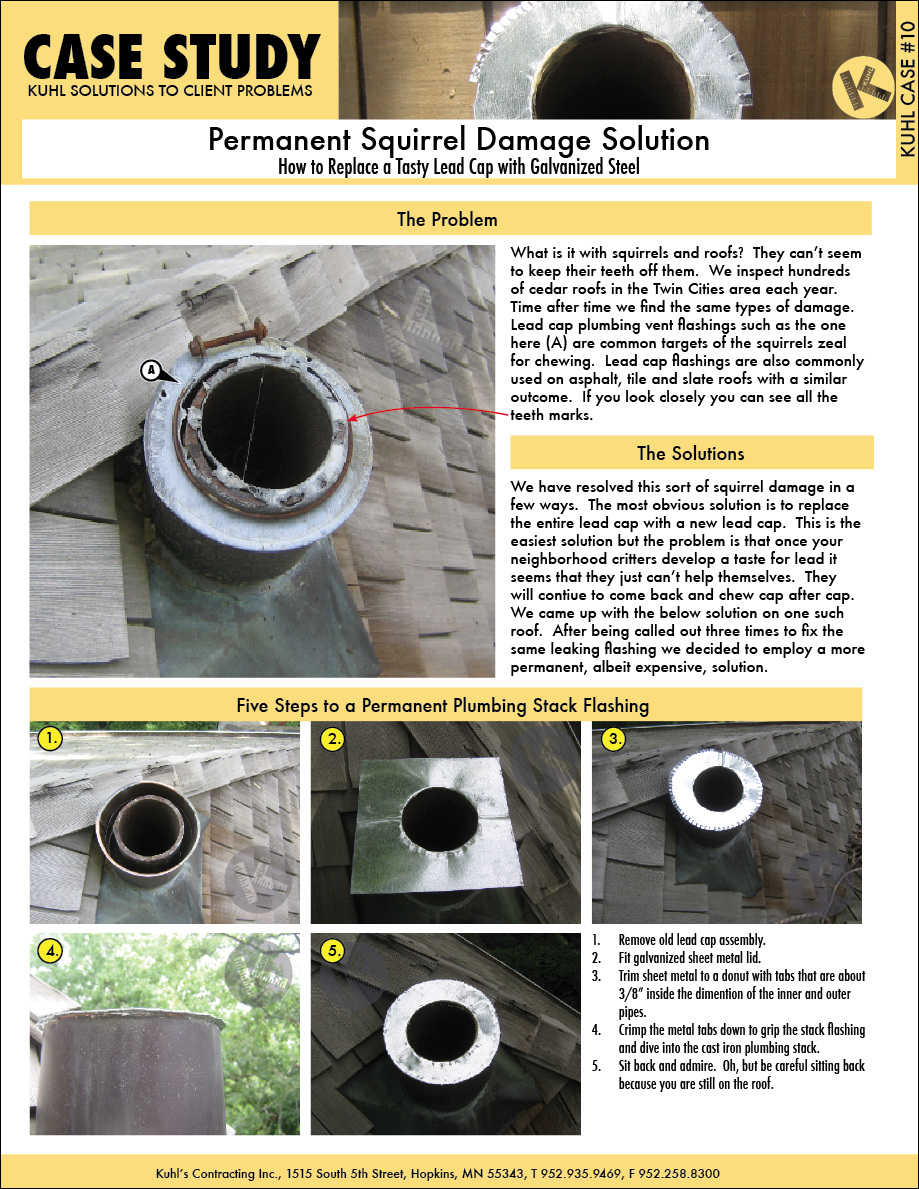

The Problem

What is it with squirrels and roofs? They can’t seem to keep their teeth off them. We inspect hundreds of cedar roofs in the Twin Cities area each year. Time after time we find the same types of damage. Lead cap plumbing vent flashings such as the one here (A) are common targets of the squirrels zeal for chewing. Lead cap flashings are also commonly used on asphalt, tile and slate roofs with a similar outcome. If you look closely you can see all the teeth marks.

The Solutions

We have resolved this sort of squirrel damage in a few ways. The most obvious solution is to replace the entire lead cap with a new lead cap. This is the easiest solution but the problem is that once your neighborhood critters develop a taste for lead it seems that they just can’t help themselves. They

will contiue to come back and chew cap after cap. We came up with the below solution on one such roof. After being called out three times to fix the same leaking flashing we decided to employ a more permanent, albeit expensive, solution.

Five Steps to a Permanent Plumbing Stack Flashing

-

Remove old lead cap assembly.

-

Fit galvanized sheet metal lid.

-

Trim sheet metal to a donut with tabs that are about 3/8” inside the dimension of the inner and outer pipes.

-

Crimp the metal tabs down to grip the stack flashing and dive into the cast iron plumbing stack.

-

Sit back and admire. Oh, but be careful sitting back because you are still on the roof.

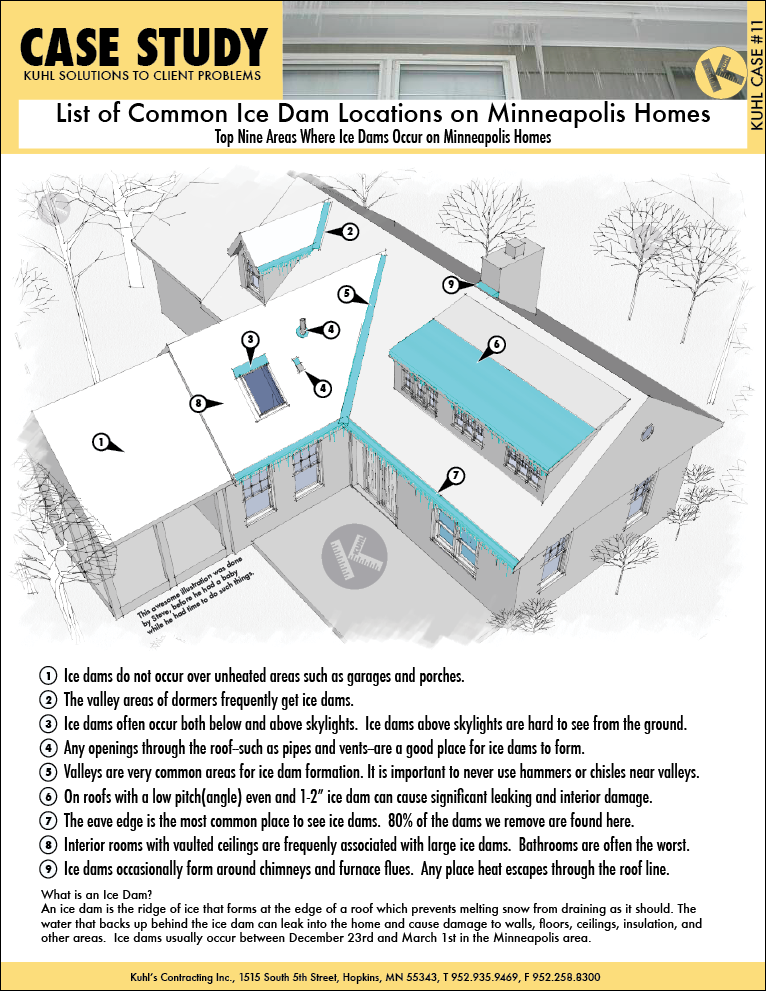

Top Nine Areas Where Ice Dams Occur on Minneapolis Homes

List of Common Ice Dam Locations on Minneapolis Homes

Top Nine Areas Where Ice Dams Occur on Minneapolis Homes

-

Ice dams do not occur over unheated areas such as garages and porches.

-

The valley areas of dormers frequently get ice dams.

-

Ice dams often occur both below and above skylights. Ice dams above skylights are hard to see from the ground.

-

Any openings through the roof–such as pipes and vents–are a good place for ice dams to form.

-

Valleys are very common areas for ice dam formation. It is important to never use hammers or chisles near valleys.

-

On roofs with a low pitch(angle) even and 1-2” ice dam can cause significant leaking and interior damage.

-

The eave edge is the most common place to see ice dams. 80% of the dams we remove are found here.

-

Interior rooms with vaulted ceilings are frequenly associated with large ice dams. Bathrooms are often the worst.

-

Ice dams occasionally form around chimneys and furnace flues. Any place heat escapes through the roof line.

What is an Ice Dam?

An ice dam is the ridge of ice that forms at the edge of a roof which prevents melting snow from draining as it should. The water that backs up behind the ice dam can leak into the home and cause damage to walls, floors, ceilings, insulation, and other areas. Ice dams usually occur between December 23rd and March 1st in the Minneapolis area.

6 Minneapolis Ice Dam Warning Signs

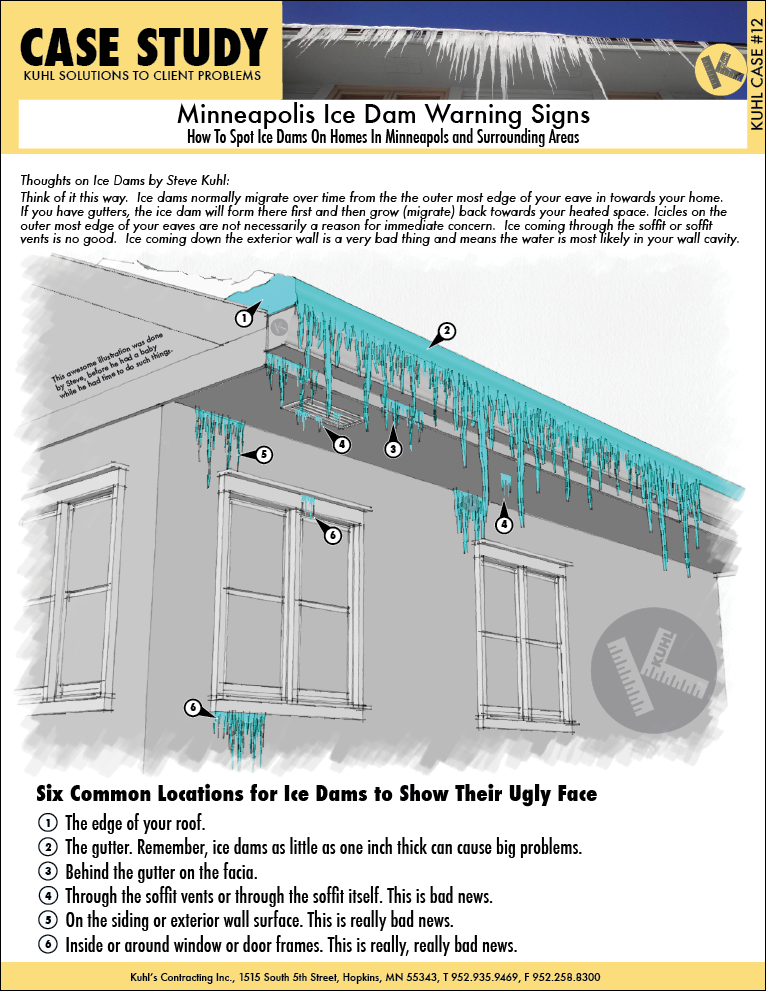

Thoughts on Ice Dams by Steve Kuhl:

Think of it this way. Ice dams normally migrate over time from the the outer most edge of your eave in towards your home.

If you have gutters, the ice dam will form there first and then grow (migrate) back towards your heated space. Icicles on the outer most edge of your eaves are not necessarily a reason for immediate concern. Ice coming through the soffit or soffit vents is no good. Ice coming down the exterior wall is a very bad thing and means the water is most likely in your wall cavity.

Six Common Locations for Ice Dams to Show Their Ugly Face

- The edge of your roof.

- The gutter. Remember, ice dams as little as one inch thick can cause big problems. Behind the gutter on the facia.

- Through the soffit vents or through the soffit itself. This is bad news.

- On the siding or exterior wall surface. This is really bad news.

- Inside or around window or door frames. This is really, really bad news.

An In-House, Design Staff Makes a Big Difference On Your Project

The Edina Heritage Awarded to Kuhl’s Contracting

Having In-House, Award Winning Design Staff Will Make a Big Difference On Your Project

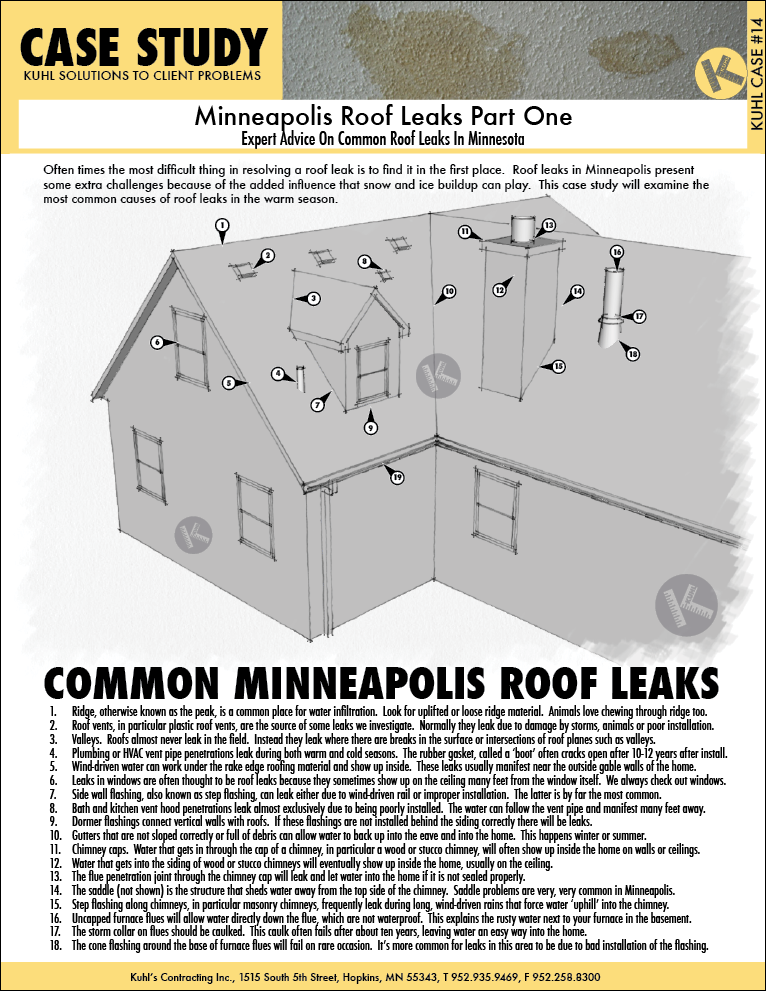

Expert Advice On Common Roof Leaks In Minnesota

Minneapolis Roof Leaks Part One

Expert Advice On Common Roof Leaks In Minnesota

Often times the most difficult thing in resolving a roof leak is to find it in the first place. Roof leaks in Minneapolis present some extra challenges because of the added influence that snow and ice buildup can play. This case study will examine the most common causes of roof leaks in the warm season.

COMMON MINNEAPOLIS ROOF LEAKS

- Ridge, otherwise known as the peak, is a common place for water infiltration. Look for uplifted or loose ridge material. Animals love chewing through ridge too.

- Roof vents, in particular plastic roof vents, are the source of some leaks we investigate. Normally they leak due to damage by storms, animals or poor installation.

- Valleys. Roofs almost never leak in the field. Instead they leak where there are breaks in the surface or intersections of roof planes such as valleys.

- Plumbing or HVAC vent pipe penetrations leak during both warm and cold seasons. The rubber gasket, called a ‘boot’ often cracks open after 10-12 years after install.

- Wind-driven water can work under the rake edge roofing material and show up inside. These leaks usually manifest near the outside gable walls of the home.

- Leaks in windows are often thought to be roof leaks because they sometimes show up on the ceiling many feet from the window itself. We always check out windows.

- Side wall flashing, also known as step flashing, can leak either due to wind-driven rail or improper installation. The latter is by far the most common.

- Bath and kitchen vent hood penetrations leak almost exclusively due to being poorly installed. The water can follow the vent pipe and manifest many feet away.

- Dormer flashings connect vertical walls with roofs. If these flashings are not installed behind the siding correctly there will be leaks.

- Gutters that are not sloped correctly or full of debris can allow water to back up into the eave and into the home. This happens winter or summer.

- Chimney caps. Water that gets in through the cap of a chimney, in particular a wood or stucco chimney, will often show up inside the home on walls or ceilings.

- Water that gets into the siding of wood or stucco chimneys will eventually show up inside the home, usually on the ceiling.

- The flue penetration joint through the chimney cap will leak and let water into the home if it is not sealed properly.

- The saddle (not shown) is the structure that sheds water away from the top side of the chimney. Saddle problems are very, very common in Minneapolis.

- Step flashing along chimneys, in particular masonry chimneys, frequently leak during long, wind-driven rains that force water ‘uphill’ into the chimney.

- Uncapped furnace flues will allow water directly down the flue, which are not waterproof. This explains the rusty water next to your furnace in the basement.

- The storm collar on flues should be caulked. This caulk often fails after about ten years, leaving water an easy way into the home.

- The cone flashing around the base of furnace flues will fail on rare occasion. It’s more common for leaks in this area to be due to bad installation of the flashing.

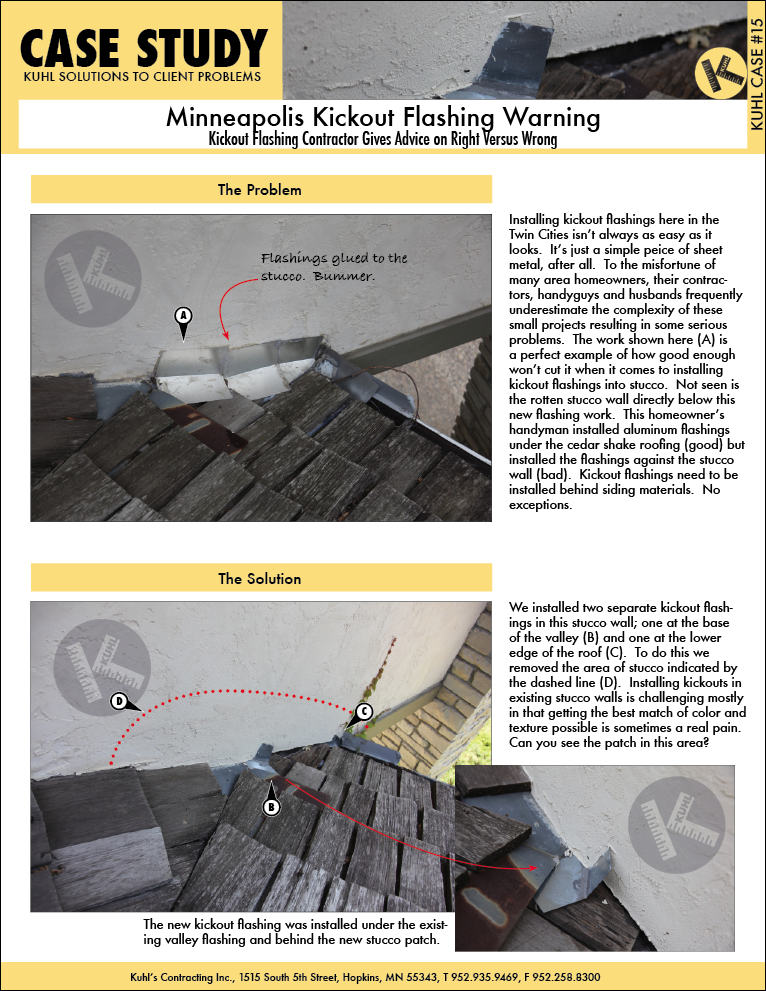

Kickout Flashing Contractor Gives Advice on Right Versus Wrong

Installing kickout flashings here in the Twin Cities isn’t always as easy as it looks. It’s just a simple peice of sheet metal, after all. To the misfortune of many area homeowners, their contrac- tors, handyguys and husbands frequently underestimate the complexity of these small projects resulting in some serious problems. The work shown here (A) is a perfect example of how good enough won’t cut it when it comes to installing kickout flashings into stucco. Not seen is the rotten stucco wall directly below this new flashing work. This homeowner’s handyman installed aluminum flashings under the cedar shake roofing (good) but installed the flashings against the stucco wall (bad). Kickout flashings need to be installed behind siding materials. No exceptions.

We installed two separate kickout flash- ings in this stucco wall; one at the base

of the valley (B) and one at the lower edge of the roof (C). To do this we removed the area of stucco indicated by the dashed line (D). Installing kickouts in existing stucco walls is challenging mostly in that getting the best match of color and texture possible is sometimes a real pain. Can you see the patch in this area?

The new kickout flashing was installed under the exist- ing valley flashing and behind the new stucco patch.

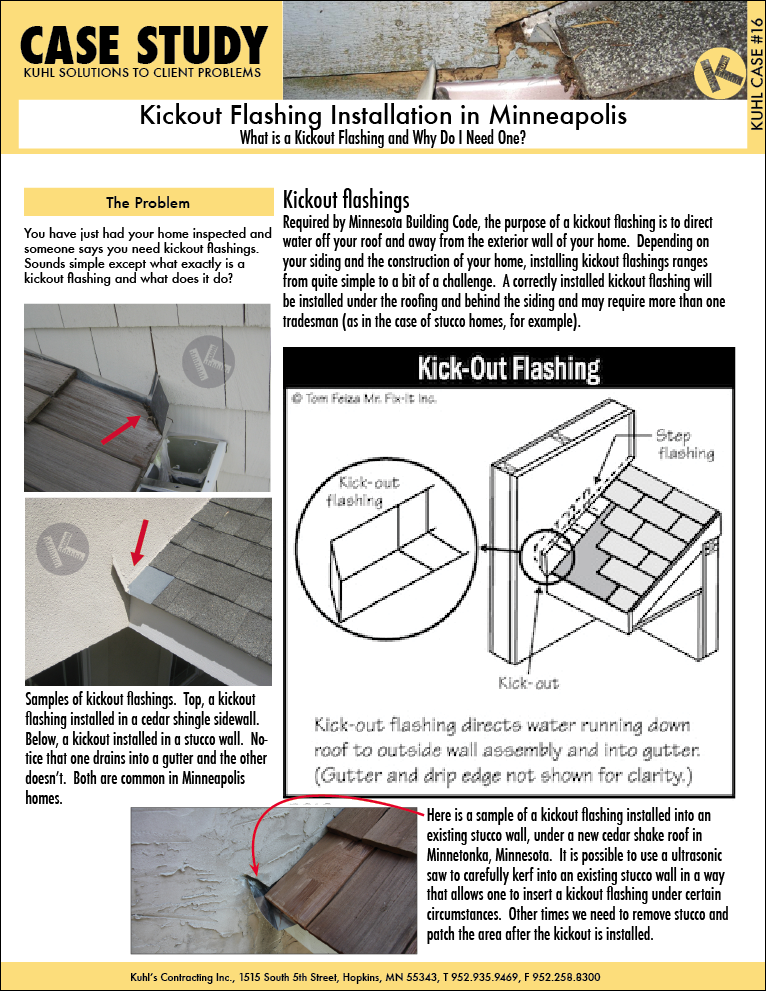

What is a Kickout Flashing and Why Do I Need One?

Kickout Flashing Installation in Minneapolis

What is a Kickout Flashing and Why Do I Need One?

The Problem

You have just had your home inspected and someone says you need kickout flashings. Sounds simple except what exactly is a kickout flashing and what does it do?

Kickout flashings

Required by Minnesota Building Code, the purpose of a kickout flashing is to direct water off your roof and away from the exterior wall of your home. Depending on your siding and the construction of your home, installing kickout flashings ranges from quite simple to a bit of a challenge. A correctly installed kickout flashing will be installed under the roofing and behind the siding and may require more than one tradesman (as in the case of stucco homes, for example).

Samples of kickout flashings. Top, a kickout flashing installed in a cedar shingle sidewall. Below, a kickout installed in a stucco wall. No- tice that one drains into a gutter and the other doesn’t. Both are common in Minneapolis homes.

Here is a sample of a kickout flashing installed into an existing stucco wall, under a new cedar shake roof in Minnetonka, Minnesota. It is possible to use a ultrasonic saw to carefully kerf into an existing stucco wall in a way that allows one to insert a kickout flashing under certain circumstances. Other times we need to remove stucco and patch the area after the kickout is installed.

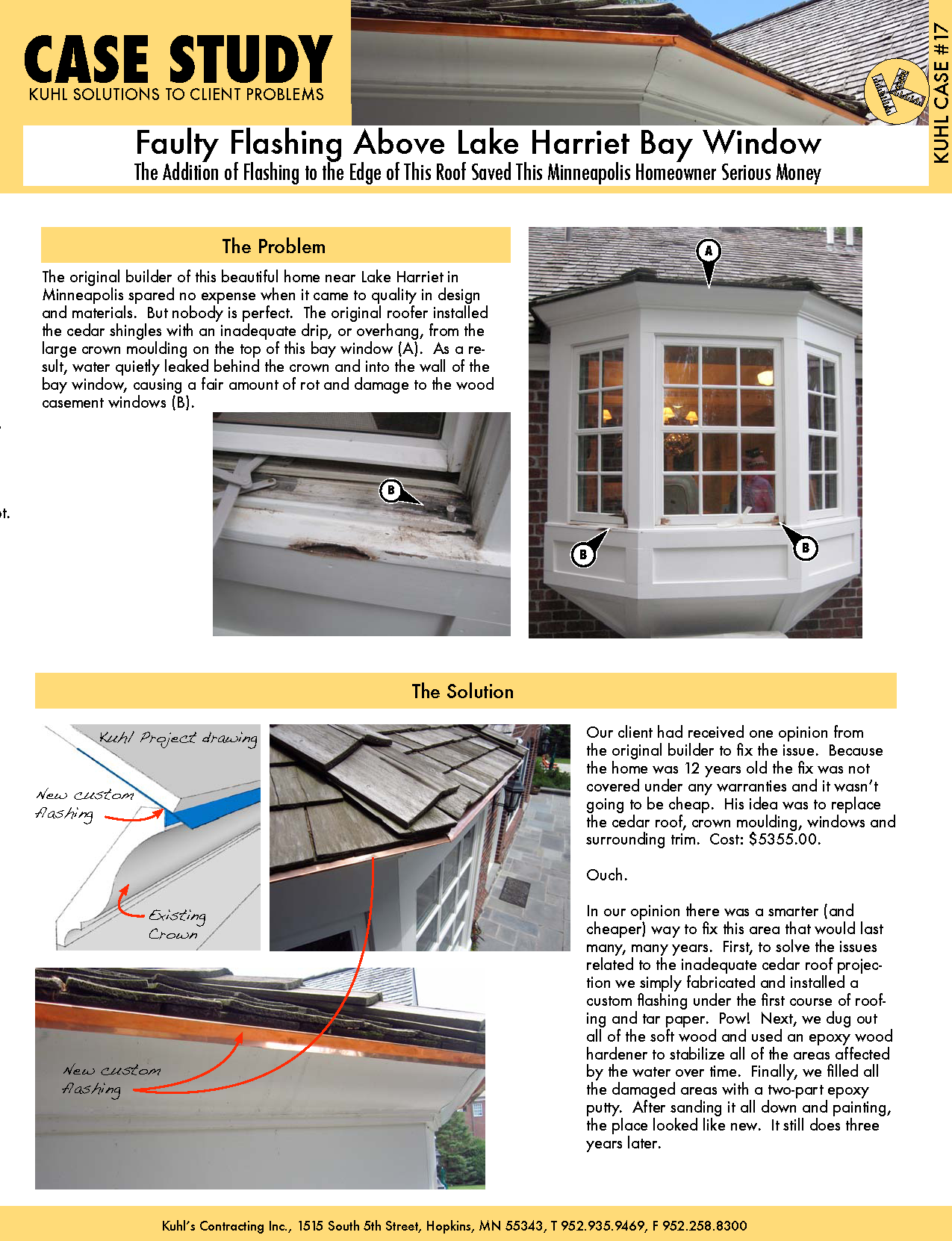

Faulty Flashing Above Lake Harriet Bay Window

The original builder of this beautiful home near Lake Harriet in

Minneapolis spared no expense when it came to quality in design

and materials. But nobody is perfect. The original roofer installed

the cedar shingles with an inadequate drip, or overhang, from the

large crown moulding on the top of this bay window (A). As a result,

water quietly leaked behind the crown and into the wall of the

bay window, causing a fair amount of rot and damage to the wood

casement windows (B).

Our client had received one opinion from

the original builder to fix the issue. Because

the home was 12 years old the fix was not

covered under any warranties and it wasn’t

going to be cheap. His idea was to replace

the cedar roof, crown moulding, windows and

surrounding trim. Cost: $5355.00.

Ouch.

In our opinion there was a smarter (and

cheaper) way to fix this area that would last

many, many years. First, to solve the issues

related to the inadequate cedar roof projection

we simply fabricated and installed a

custom flashing under the first course of roofing

and tar paper. Pow! Next, we dug out

all of the soft wood and used an epoxy wood

hardener to stabilize all of the areas affected

by the water over time. Finally, we filled all

the damaged areas with a two-part epoxy

putty. After sanding it all down and painting,

the place looked like new. It still does three

years later.

mullions!

rot.

Kuhl’s Contracting Inc., 1515 South 5th Street, Hopkins, MN 55343, T 952.935.9469, F 952.258.8300

KUHL CASE #17

The Problem

The Solution

KUHL SOLUTIONS TO CLIENT PROBLEMS

Leaking Stucco Chimney Solution

Kuhl’s Contracting Inc., 1515 South 5th Street, Hopkins, MN 55343, T 952.935.9469, F 952.258.8300

KUHL SOLUTIONS TO CLIENT PROBLEMS CASE STUDY

KUHL CASE #18

Leaking Stucco Chimney Solution

Stucco Home in Eden Prairie Has Damage That Needed Fixing

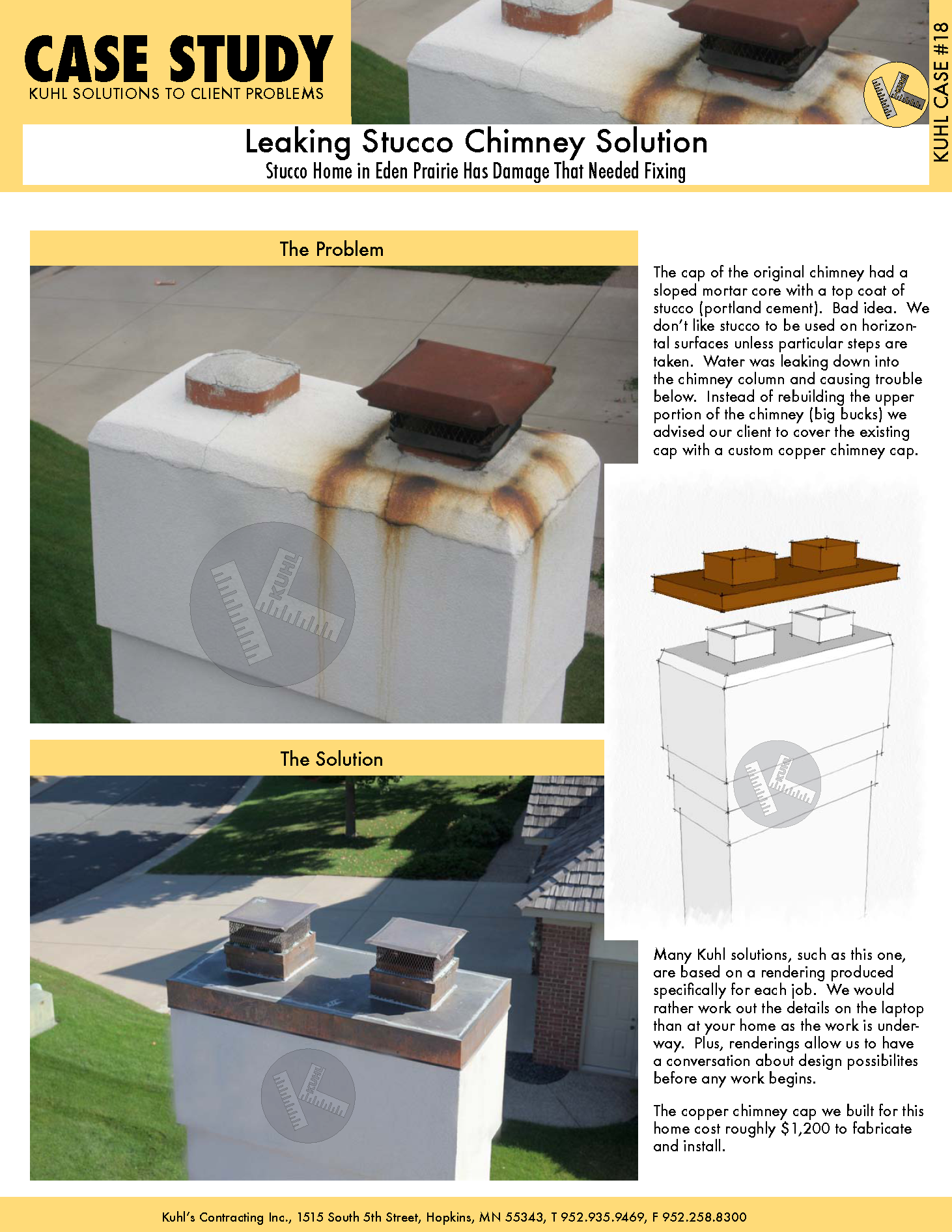

The cap of the original chimney had a

sloped mortar core with a top coat of

stucco (portland cement). Bad idea. We

don’t like stucco to be used on horizontal

surfaces unless particular steps are

taken. Water was leaking down into

the chimney column and causing trouble

below. Instead of rebuilding the upper

portion of the chimney (big bucks) we

advised our client to cover the existing

cap with a custom copper chimney cap.

The Problem

The Solution

Many Kuhl solutions, such as this one,

are based on a rendering produced

specifically for each job. We would

rather work out the details on the laptop

than at your home as the work is underway.

Plus, renderings allow us to have

a conversation about design possibilites

before any work begins.

The copper chimney cap we built for this

home cost roughly $1,200 to fabricate

and install.

What Does Hail Damage Look Like, Part 1

Kuhl’s Contracting Inc., 1515 South 5th Street, Hopkins, MN 55343, T 952.935.9469, F 952.258.8300

KUHL SOLUTIONS TO CLIENT PROBLEMS CASE STUDY

What Does Hail Damage Look Like, Part One

Minneapolis Hail Storms Leaves Clear Evidence Behind

KUHL CASE #20

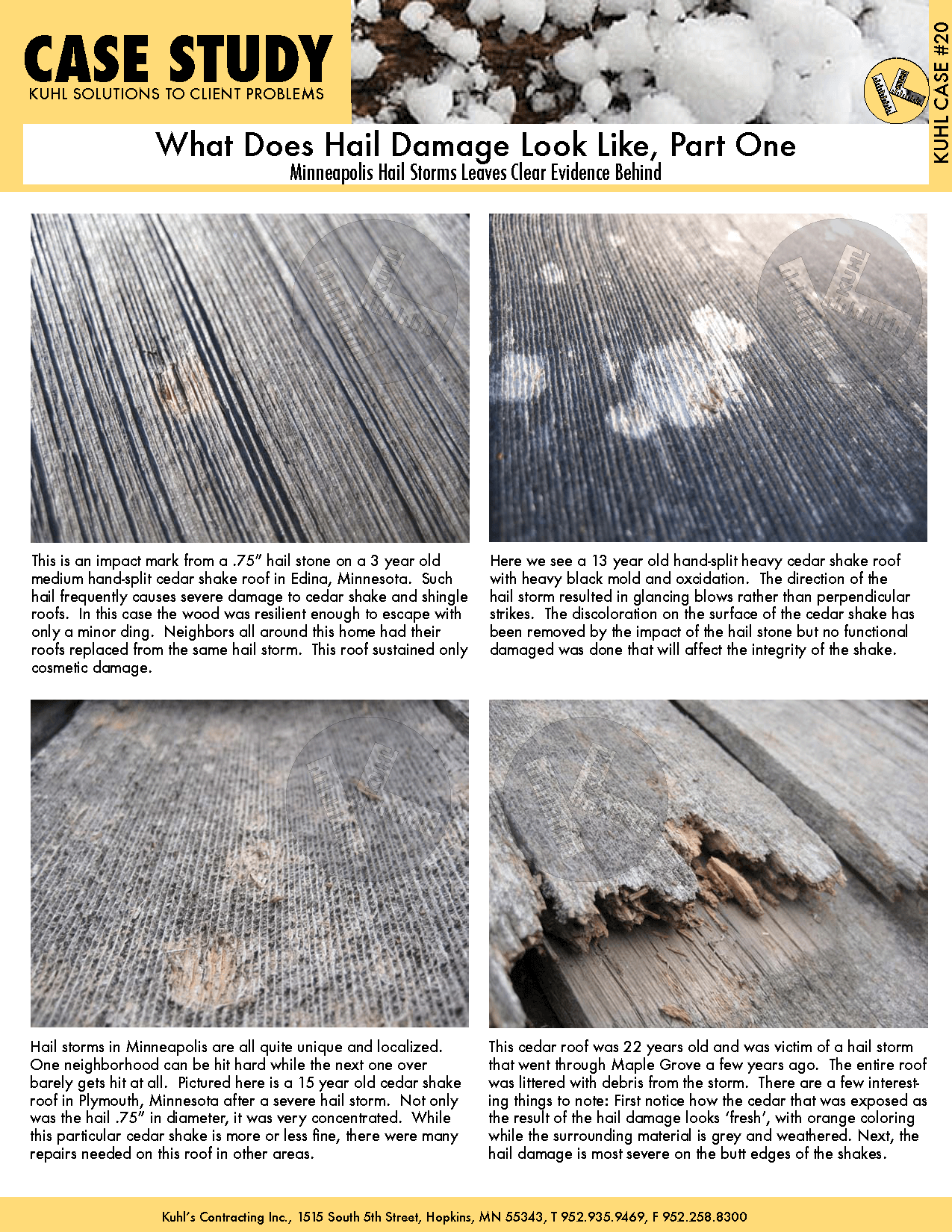

This is an impact mark from a .75” hail stone on a 3 year old

medium hand-split cedar shake roof in Edina, Minnesota. Such

hail frequently causes severe damage to cedar shake and shingle

roofs. In this case the wood was resilient enough to escape with

only a minor ding. Neighbors all around this home had their

roofs replaced from the same hail storm. This roof sustained only

cosmetic damage.

Hail storms in Minneapolis are all quite unique and localized.

One neighborhood can be hit hard while the next one over

barely gets hit at all. Pictured here is a 15 year old cedar shake

roof in Plymouth, Minnesota after a severe hail storm. Not only

was the hail .75” in diameter, it was very concentrated. While

this particular cedar shake is more or less fine, there were many

repairs needed on this roof in other areas.

Here we see a 13 year old hand-split heavy cedar shake roof

with heavy black mold and oxcidation. The direction of the

hail storm resulted in glancing blows rather than perpendicular

strikes. The discoloration on the surface of the cedar shake has

been removed by the impact of the hail stone but no functional

damaged was done that will affect the integrity of the shake.

This cedar roof was 22 years old and was victim of a hail storm

that went through Maple Grove a few years ago. The entire roof

was littered with debris from the storm. There are a few interesting

things to note: First notice how the cedar that was exposed as

the result of the hail damage looks ‘fresh’, with orange coloring

while the surrounding material is grey and weathered. Next, the

hail damage is most severe on the butt edges of the shakes.

What Does Hail Damage Look Like, Part 2

Kuhl’s Contracting Inc., 1515 South 5th Street, Hopkins, MN 55343, T 952.935.9469, F 952.258.8300

KUHL CASE #20

KUHL SOLUTIONS TO CLIENT PROBLEMS CASE STUDY

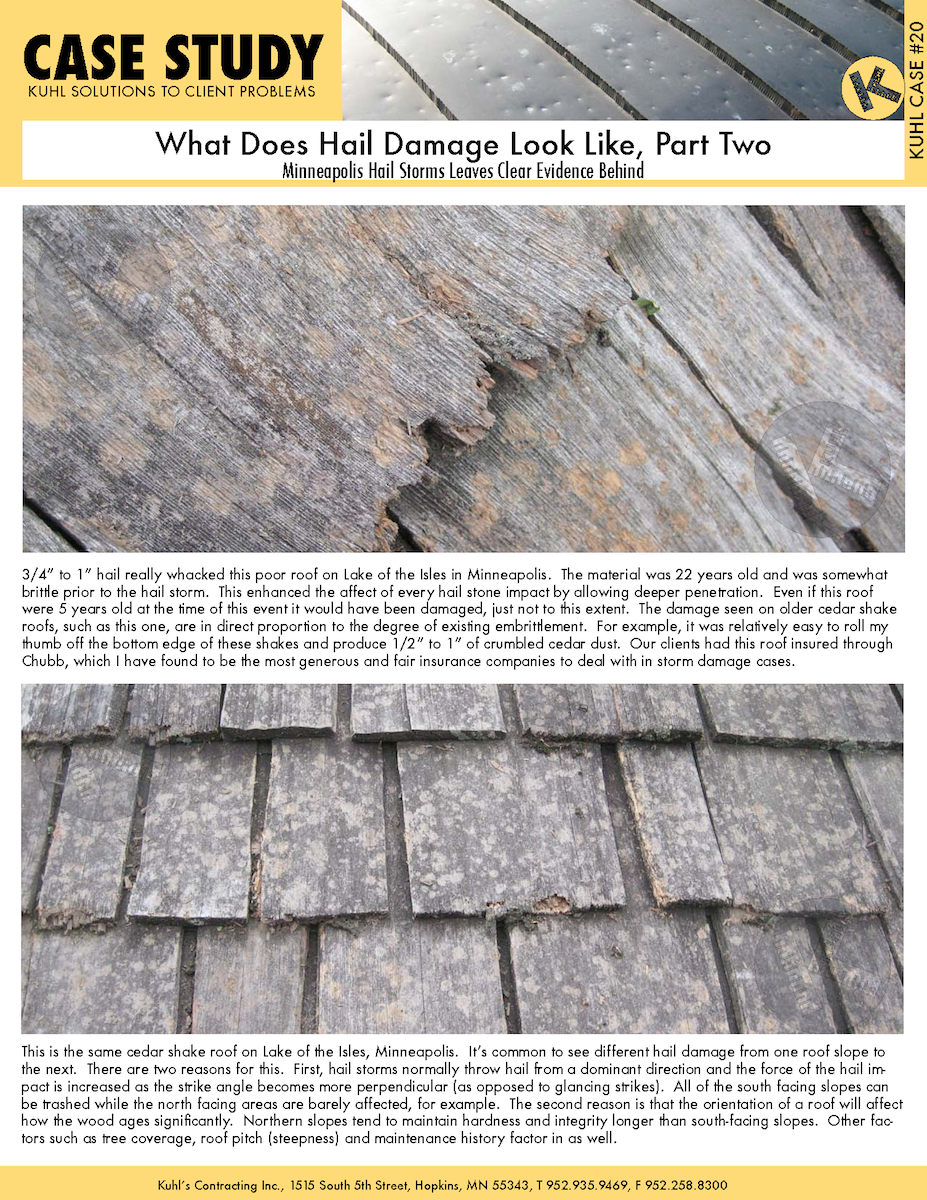

3/4” to 1” hail really whacked this poor roof on Lake of the Isles in Minneapolis. The material was 22 years old and was somewhat

brittle prior to the hail storm. This enhanced the affect of every hail stone impact by allowing deeper penetration. Even if this roof

were 5 years old at the time of this event it would have been damaged, just not to this extent. The damage seen on older cedar shake

roofs, such as this one, are in direct proportion to the degree of existing embrittlement. For example, it was relatively easy to roll my

thumb off the bottom edge of these shakes and produce 1/2” to 1” of crumbled cedar dust. Our clients had this roof insured through

Chubb, which I have found to be the most generous and fair insurance companies to deal with in storm damage cases.

This is the same cedar shake roof on Lake of the Isles, Minneapolis. It’s common to see different hail damage from one roof slope to

the next. There are two reasons for this. First, hail storms normally throw hail from a dominant direction and the force of the hail impact

is increased as the strike angle becomes more perpendicular (as opposed to glancing strikes). All of the south facing slopes can

be trashed while the north facing areas are barely affected, for example. The second reason is that the orientation of a roof will affect

how the wood ages significantly. Northern slopes tend to maintain hardness and integrity longer than south-facing slopes. Other factors

such as tree coverage, roof pitch (steepness) and maintenance history factor in as well.

What Does Hail Damage Look Like, Part Two

Minneapolis Hail Storms Leaves Clear Evidence Behind

Ice Dam Puzzle: Minneapolis Ice Dam Prevention

Ice Dam Puzzle

Minneapolis Homeowner Struggled to Find Educated Perspective on Ice Dam Mystery

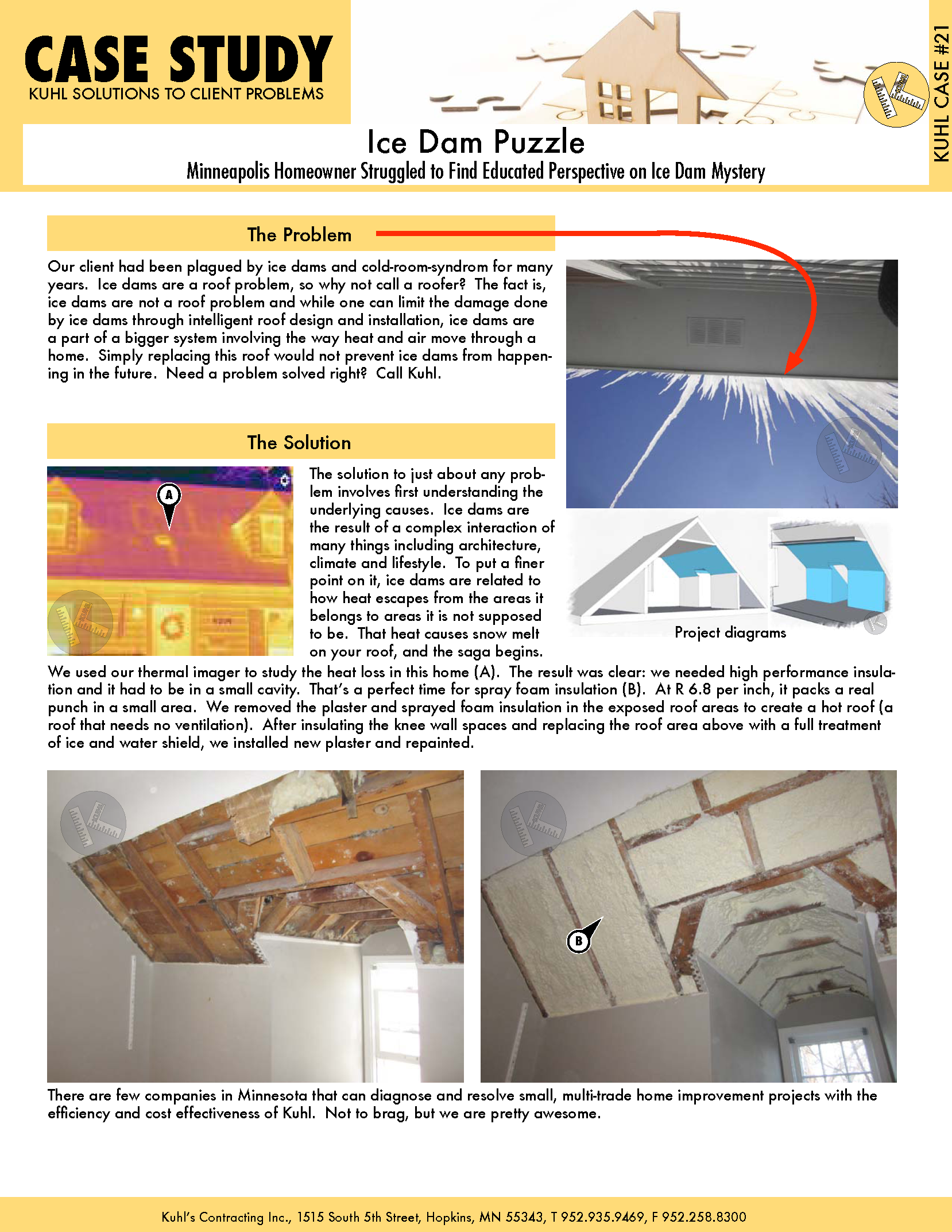

The Problem

Our client had been plagued by ice dams and cold-room-syndrom for many

years. Ice dams are a roof problem, so why not call a roofer? The fact is,

ice dams are not a roof problem and while one can limit the damage done

by ice dams through intelligent roof design and installation, ice dams are

a part of a bigger system involving the way heat and air move through a

home. Simply replacing this roof would not prevent ice dams from happening

in the future. Need a problem solved right? Call Kuhl.

The Solution

The solution to just about any problem

involves first understanding the

underlying causes. Ice dams are

the result of a complex interaction of

many things including architecture,

climate and lifestyle. To put a finer

point on it, ice dams are related to

how heat escapes from the areas it

belongs to areas it is not supposed

to be. That heat causes snow melt

on your roof, and the saga begins.

We used our thermal imager to study the heat loss in this home (A). The result was clear: we needed high performance insulation

and it had to be in a small cavity. That’s a perfect time for spray foam insulation (B). At R 6.8 per inch, it packs a real

punch in a small area. We removed the plaster and sprayed foam insulation in the exposed roof areas to create a hot roof (a

roof that needs no ventilation). After insulating the knee wall spaces and replacing the roof area above with a full treatment

of ice and water shield, we installed new plaster and repainted.

Solving The Mystery Leak: Using Darkness to Find the Light

Solving the Mystery Leak

CASE STUDY

KUHL CASE #22

Kuhl’s Contracting Inc., 1515 South 5th Street, Hopkins, MN 55343, T 952.935.9469, F 952.258.8300

The Problem The Backstory

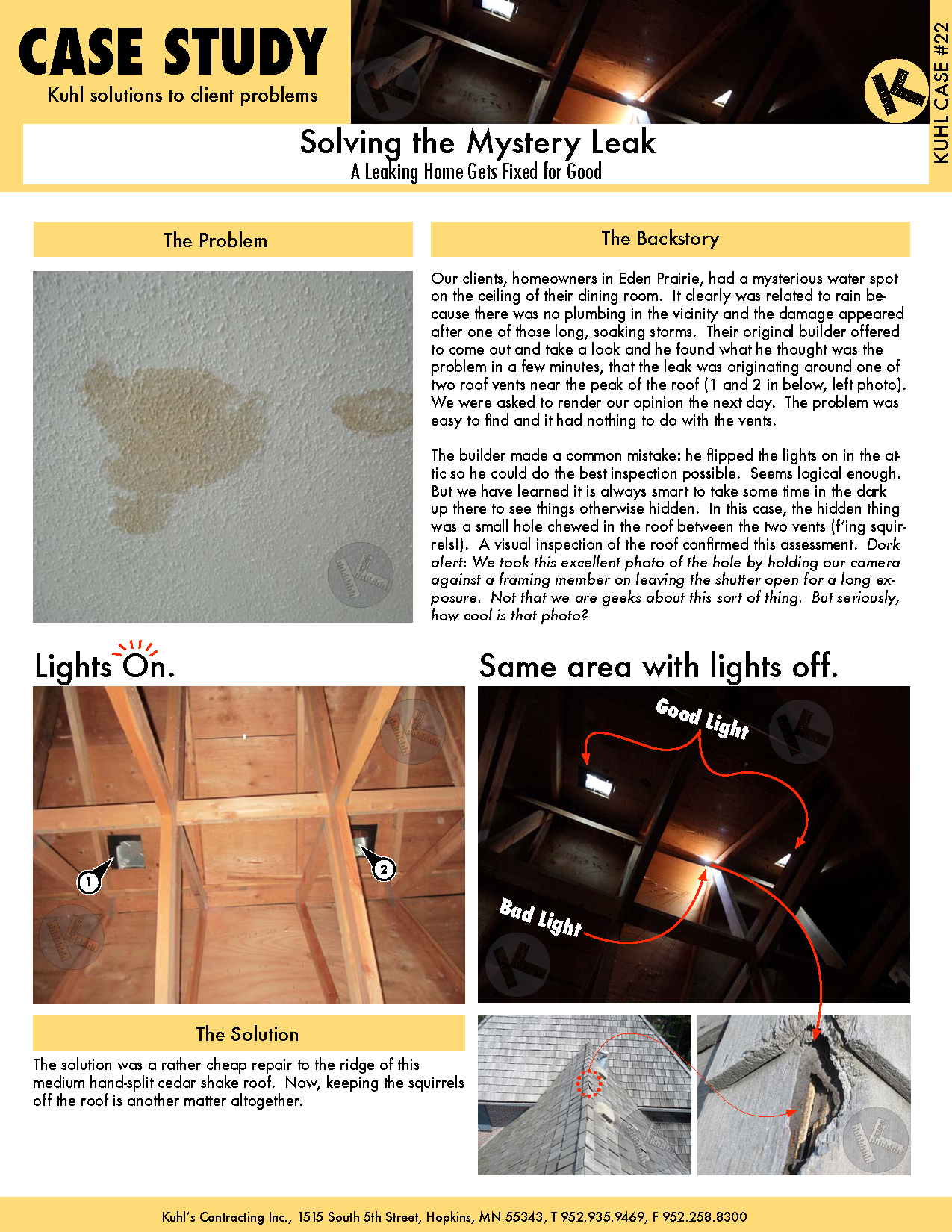

The solution was a rather cheap repair to the ridge of this

medium hand-split cedar shake roof. Now, keeping the squirrels

off the roof is another matter altogether.

The Solution

Our clients, homeowners in Eden Prairie, had a mysterious water spot

on the ceiling of their dining room. It clearly was related to rain because

there was no plumbing in the vicinity and the damage appeared

after one of those long, soaking storms. Their original builder offered

to come out and take a look and he found what he thought was the

problem in a few minutes, that the leak was originating around one of

two roof vents near the peak of the roof (1 and 2 in below, left photo).

We were asked to render our opinion the next day. The problem was

easy to find and it had nothing to do with the vents.

The builder made a common mistake: he flipped the lights on in the attic

so he could do the best inspection possible. Seems logical enough.

But we have learned it is always smart to take some time in the dark

up there to see things otherwise hidden. In this case, the hidden thing

was a small hole chewed in the roof between the two vents (f’ing squirrels!).

A visual inspection of the roof confirmed this assessment. Dork

alert: We took this excellent photo of the hole by holding our camera

against a framing member on leaving the shutter open for a long exposure.

Not that we are geeks about this sort of thing. But seriously,

how cool is that photo?

Lights On.

A Leaking Home Gets Fixed for Good

Hiring a Cedar Roof Restoration Contractor: Honesty + Experience

But I just need my roof washed…

Cedar Roof Cleaning Expert Rescues Excelsior Homeowner from Other ‘Expert’

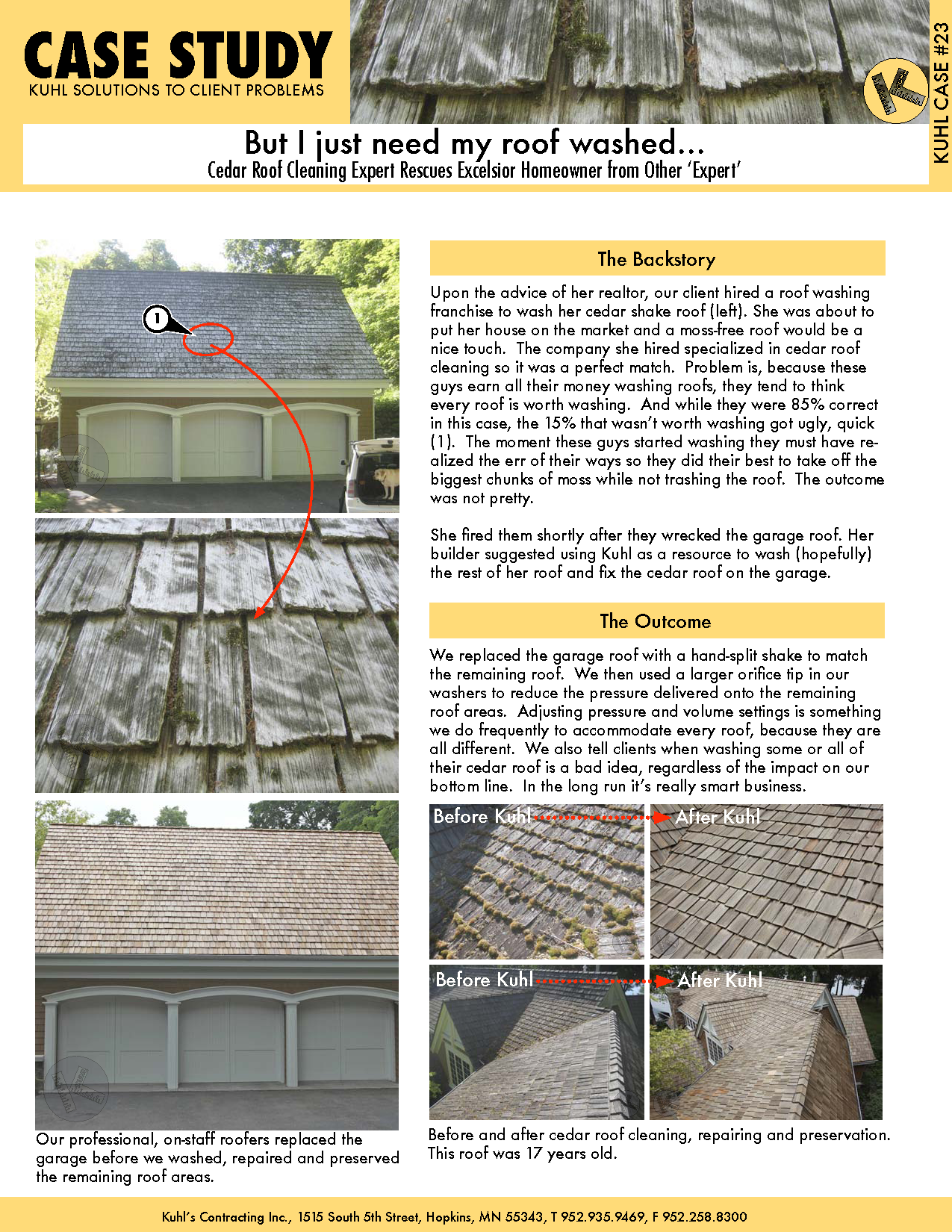

Upon the advice of her realtor, our client hired a roof washing

franchise to wash her cedar shake roof (left). She was about to

put her house on the market and a moss-free roof would be a

nice touch. The company she hired specialized in cedar roof

cleaning so it was a perfect match. Problem is, because these

guys earn all their money washing roofs, they tend to think

every roof is worth washing. And while they were 85% correct

in this case, the 15% that wasn’t worth washing got ugly, quick

(1). The moment these guys started washing they must have realized

the err of their ways so they did their best to take off the

biggest chunks of moss while not trashing the roof. The outcome

was not pretty.

She fired them shortly after they wrecked the garage roof. Her

builder suggested using Kuhl as a resource to wash (hopefully)

the rest of her roof and fix the cedar roof on the garage.

We replaced the garage roof with a hand-split shake to match

the remaining roof. We then used a larger orifice tip in our

washers to reduce the pressure delivered onto the remaining

roof areas. Adjusting pressure and volume settings is something

we do frequently to accommodate every roof, because they are

all different. We also tell clients when washing some or all of

their cedar roof is a bad idea, regardless of the impact on our

bottom line. In the long run it’s really smart business.

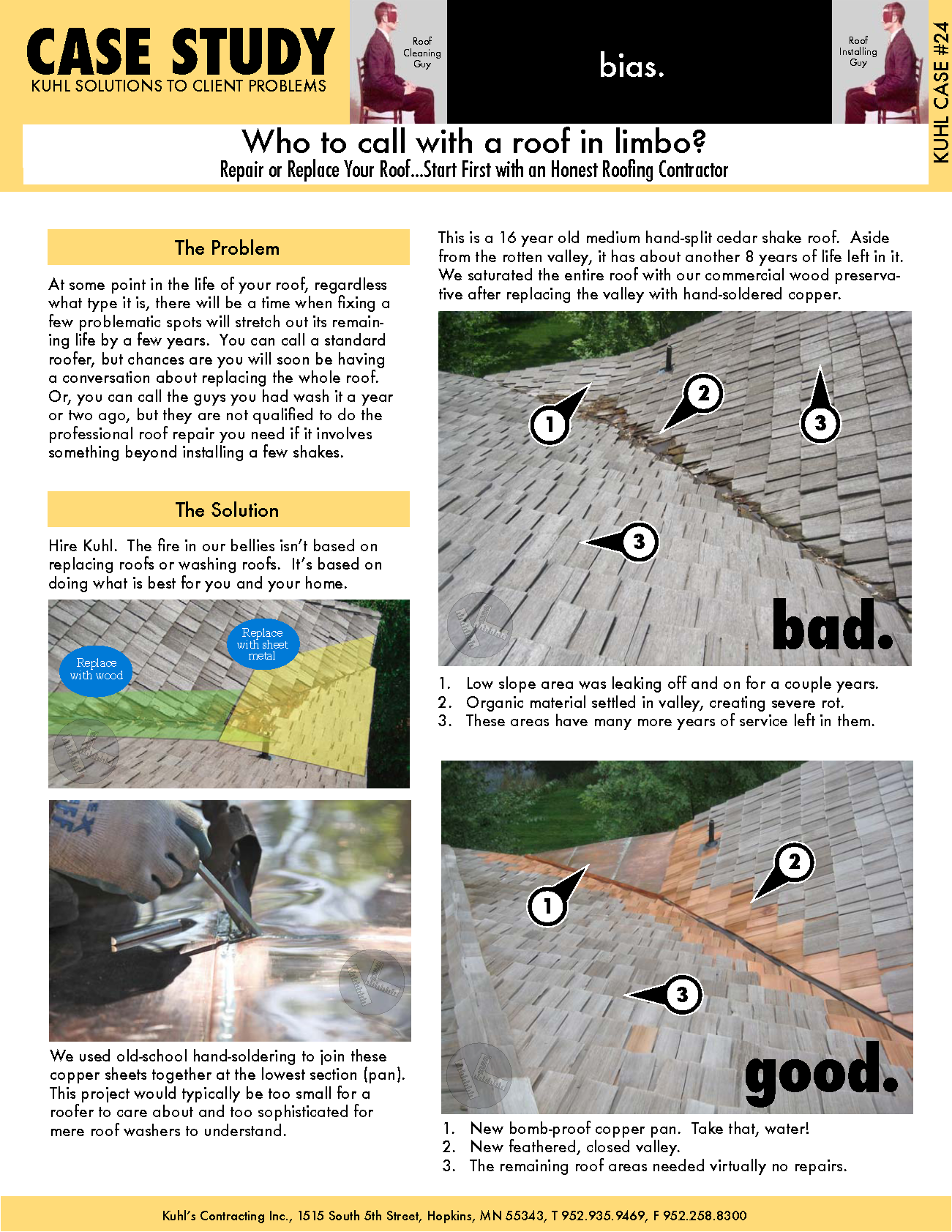

Who to call with a roof in limbo: Should You Replace or Repair Your Roof

Who to call with a roof in limbo?

Repair or Replace Your Roof…Start First with an Honest Roofing Contractor

The Problem

At some point in the life of your roof, regardless

what type it is, there will be a time when fixing a

few problematic spots will stretch out its remaining

life by a few years. You can call a standard

roofer, but chances are you will soon be having

a conversation about replacing the whole roof.

Or, you can call the guys you had wash it a year

or two ago, but they are not qualified to do the

professional roof repair you need if it involves

something beyond installing a few shakes.

This is a 16 year old medium hand-split cedar shake roof. Aside

from the rotten valley, it has about another 8 years of life left in it.

We saturated the entire roof with our commercial wood preservative

after replacing the valley with hand-soldered copper.

1. Low slope area was leaking off and on for a couple years.

2. Organic material settled in valley, creating severe rot.

3. These areas have many more years of service left in them.

The Solution

Hire Kuhl. The fire in our bellies isn’t based on

replacing roofs or washing roofs. It’s based on

doing what is best for you and your home.

We used old-school hand-soldering to join these

copper sheets together at the lowest section (pan).

This project would typically be too small for a

roofer to care about and too sophisticated for

mere roof washers to understand.

1. New bomb-proof copper pan. Take that, water!

2. New feathered, closed valley.

3. The remaining roof areas needed virtually no repairs.

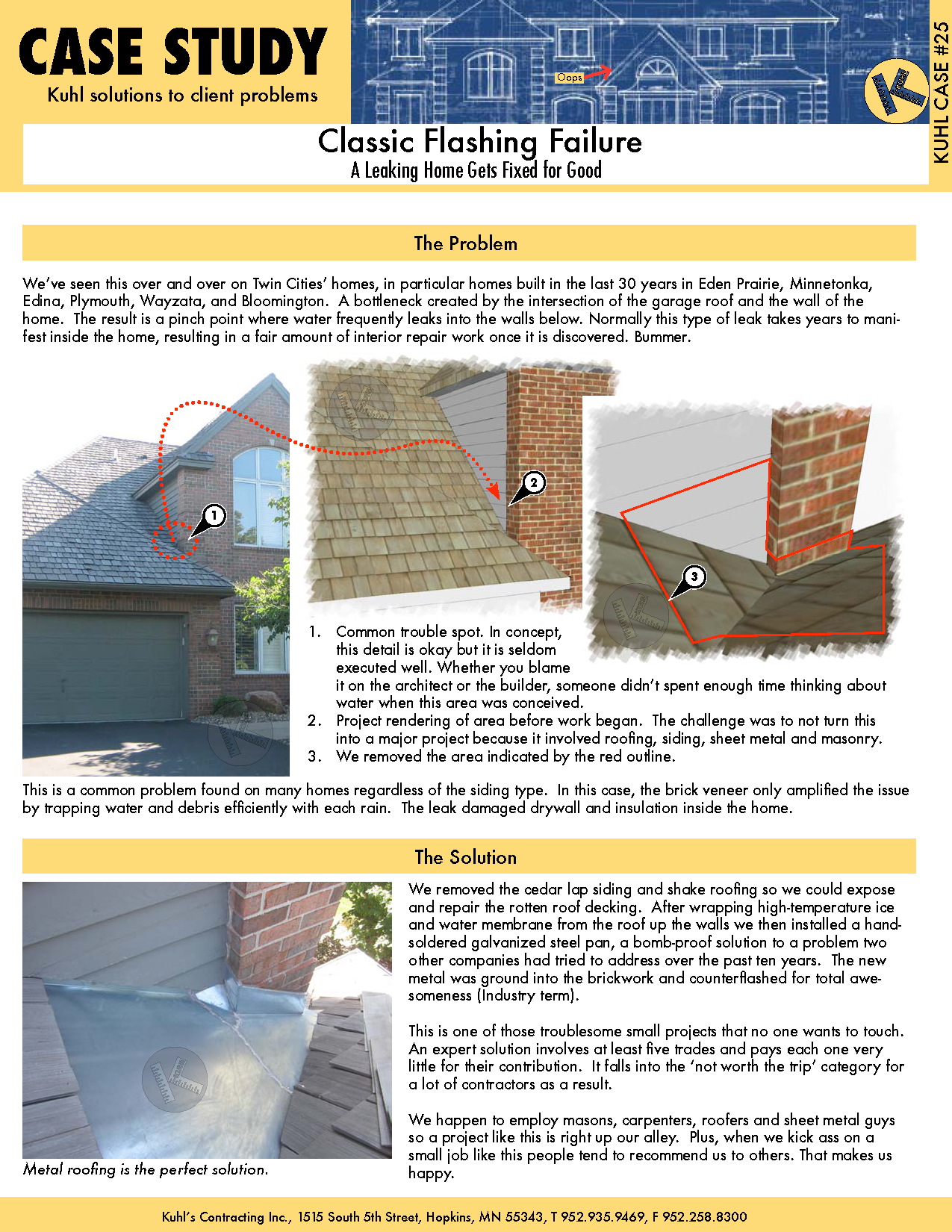

Classic Flashing Failure: Roof Flashing Experts to the Rescue

Classic Flashing Failure

CASE STUDY

We removed the cedar lap siding and shake roofing so we could expose

and repair the rotten roof decking. After wrapping high-temperature ice

and water membrane from the roof up the walls we then installed a handsoldered

galvanized steel pan, a bomb-proof solution to a problem two

other companies had tried to address over the past ten years. The new

metal was ground into the brickwork and counterflashed for total awesomeness

(Industry term).

This is one of those troublesome small projects that no one wants to touch.

An expert solution involves at least five trades and pays each one very

little for their contribution. It falls into the ‘not worth the trip’ category for

a lot of contractors as a result.

We happen to employ masons, carpenters, roofers and sheet metal guys

so a project like this is right up our alley. Plus, when we kick ass on a

small job like this people tend to recommend us to others. That makes us

happy.

We’ve seen this over and over on Twin Cities’ homes, in particular homes built in the last 30 years in Eden Prairie, Minnetonka,

Edina, Plymouth, Wayzata, and Bloomington. A bottleneck created by the intersection of the garage roof and the wall of the

home. The result is a pinch point where water frequently leaks into the walls below. Normally this type of leak takes years to manifest

inside the home, resulting in a fair amount of interior repair work once it is discovered. Bummer.

This is a common problem found on many homes regardless of the siding type. In this case, the brick veneer only amplified the issue

by trapping water and debris efficiently with each rain. The leak damaged drywall and insulation inside the home.

Metal roofing is the perfect solution.

KUHL CASE #25

Kuhl’s Contracting Inc., 1515 South 5th Street, Hopkins, MN 55343, T 952.935.9469, F 952.258.8300

The Problem

The Solution

Oops

1. Common trouble spot. In concept,

this detail is okay but it is seldom

executed well. Whether you blame

it on the architect or the builder, someone didn’t spent enough time thinking about

water when this area was conceived.

2. Project rendering of area before work began. The challenge was to not turn this

into a major project because it involved roofing, siding, sheet metal and masonry.

3. We removed the area indicated by the red outline.

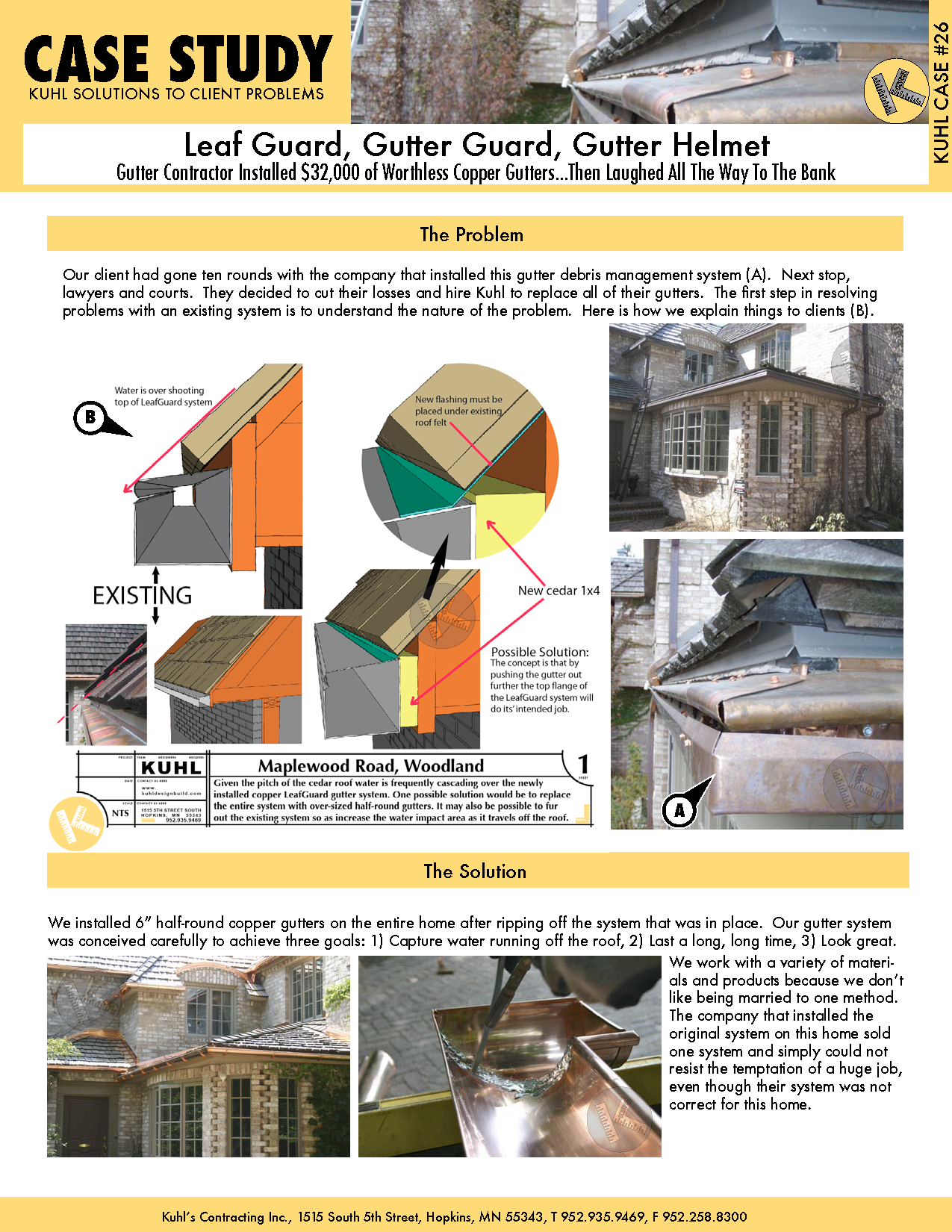

Leaf Guard, Gutter Guard, Gutter Helmet

Leaf Guard, Gutter Guard, Gutter Helmet

Gutter Contractor Installed $32,000 of Worthless Copper Gutters…Then Laughed All The Way To The Bank

The Problem

Our client had gone ten rounds with the company that installed this gutter debris management system (A). Next stop,

lawyers and courts. They decided to cut their losses and hire Kuhl to replace all of their gutters. The first step in resolving

problems with an existing system is to understand the nature of the problem. Here is how we explain things to clients (B).

The Solution

We installed 6” half-round copper gutters on the entire home after ripping off the system that was in place. Our gutter system

was conceived carefully to achieve three goals: 1) Capture water running off the roof, 2) Last a long, long time, 3) Look great.

We work with a variety of materials

and products because we don’t

like being married to one method.

The company that installed the

original system on this home sold

one system and simply could not

resist the temptation of a huge job,

even though their system was not

correct for this home.

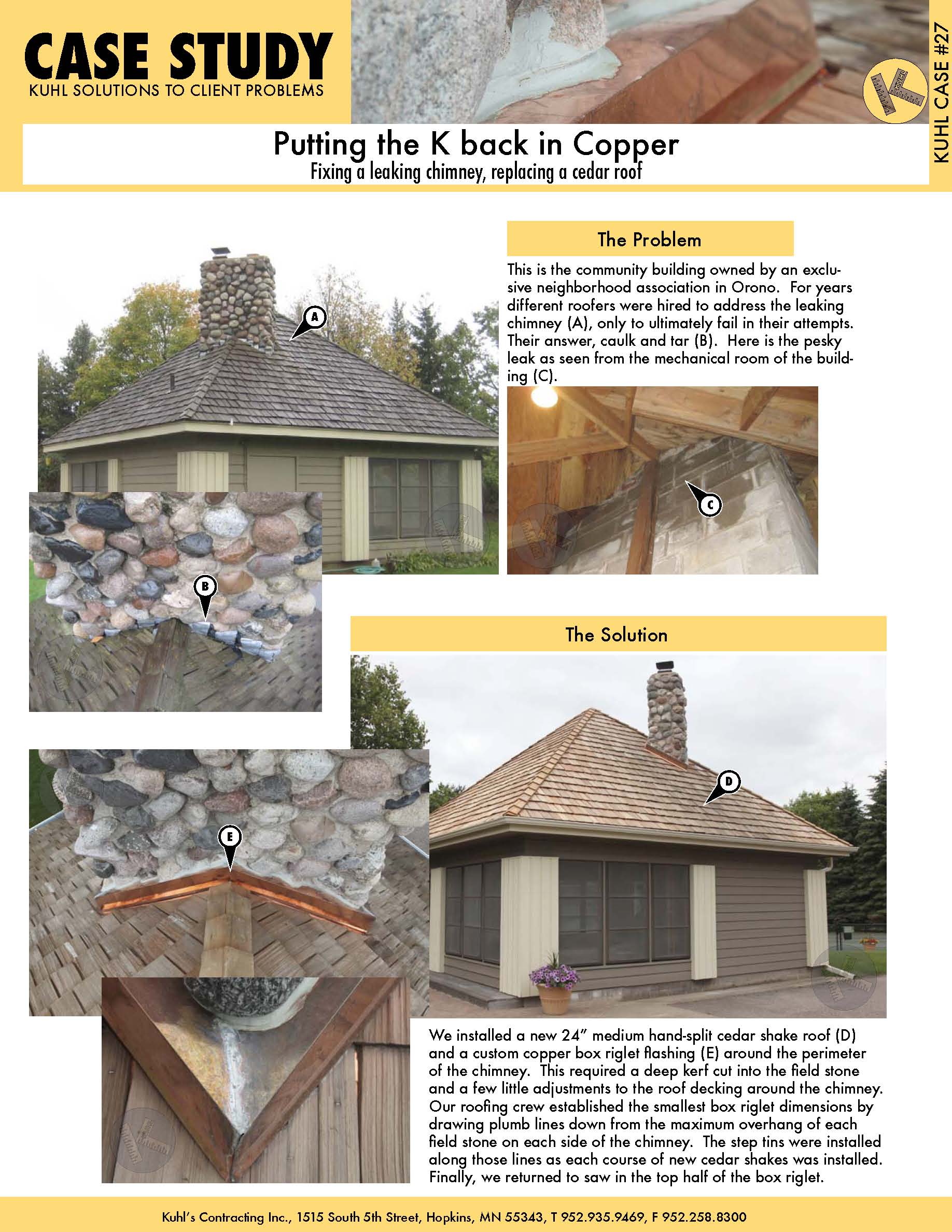

Putting the K Back in Copper: How to Fix a Leaking Stone Chimney

Putting the K back in Copper

Fixing a leaking chimney, replacing a cedar roof

The Problem

This is the community building owned by an exclusive

neighborhood association in Orono. For years

different roofers were hired to address the leaking

chimney (A), only to ultimately fail in their attempts.

Their answer, caulk and tar (B). Here is the pesky

leak as seen from the mechanical room of the building

(C).

The Solution

We installed a new 24” medium hand-split cedar shake roof (D)

and a custom copper box riglet flashing (E) around the perimeter

of the chimney. This required a deep kerf cut into the field stone

and a few little adjustments to the roof decking around the chimney.

Our roofing crew established the smallest box riglet dimensions by

drawing plumb lines down from the maximum overhang of each

field stone on each side of the chimney. The step tins were installed

along those lines as each course of new cedar shakes was installed.

Finally, we returned to saw in the top half of the box riglet.

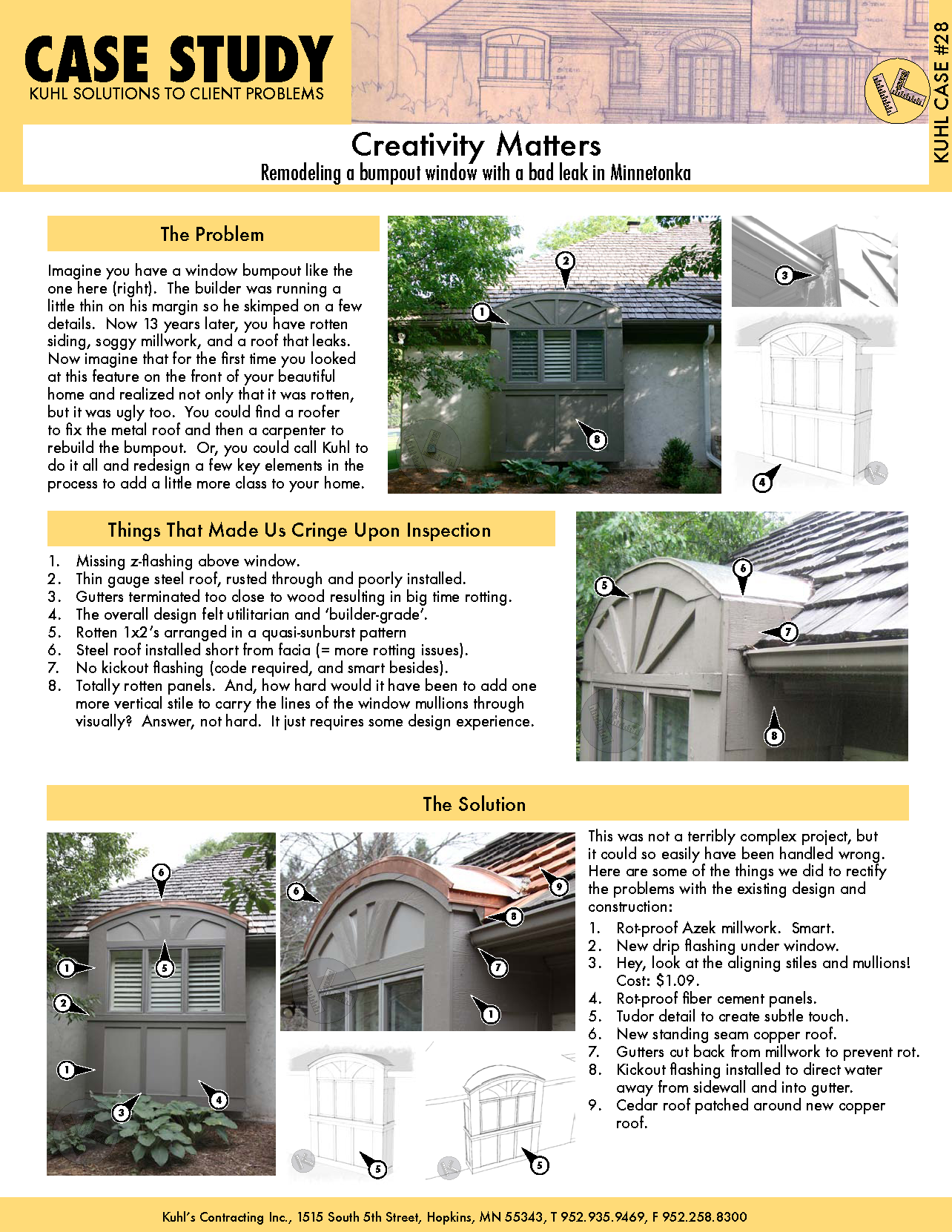

Creativity Matters: How to Fix a Leaking Window

Creativity Matters

Remodeling a bumpout window with a bad leak in Minnetonka

The Problem

Imagine you have a window bumpout like the

one here (right). The builder was running a

little thin on his margin so he skimped on a few

details. Now 13 years later, you have rotten

siding, soggy millwork, and a roof that leaks.

Now imagine that for the first time you looked

at this feature on the front of your beautiful

home and realized not only that it was rotten,

but it was ugly too. You could find a roofer

to fix the metal roof and then a carpenter to

rebuild the bumpout. Or, you could call Kuhl to

do it all and redesign a few key elements in the

process to add a little more class to your home.

Things That Made Us Cringe Upon Inspection

1. Missing z-flashing above window.

2. Thin gauge steel roof, rusted through and poorly installed.

3. Gutters terminated too close to wood resulting in big time rotting.

4. The overall design felt utilitarian and ‘builder-grade’.

5. Rotten 1×2’s arranged in a quasi-sunburst pattern

6. Steel roof installed short from facia (= more rotting issues).

7. No kickout flashing (code required, and smart besides).

8. Totally rotten panels. And, how hard would it have been to add one

more vertical stile to carry the lines of the window mullions through

visually? Answer, not hard. It just requires some design experience.

The Solution

This was not a terribly complex project, but

it could so easily have been handled wrong.

Here are some of the things we did to rectify

the problems with the existing design and

construction:

1. Rot-proof Azek millwork. Smart.

2. New drip flashing under window.

3. Hey, look at the aligning stiles and mullions!

Cost: $1.09.

4. Rot-proof fiber cement panels.

5. Tudor detail to create subtle touch.

6. New standing seam copper roof.

7. Gutters cut back from millwork to prevent rot.

8. Kickout flashing installed to direct water

away from sidewall and into gutter.

9. Cedar roof patched around new copper

roof.

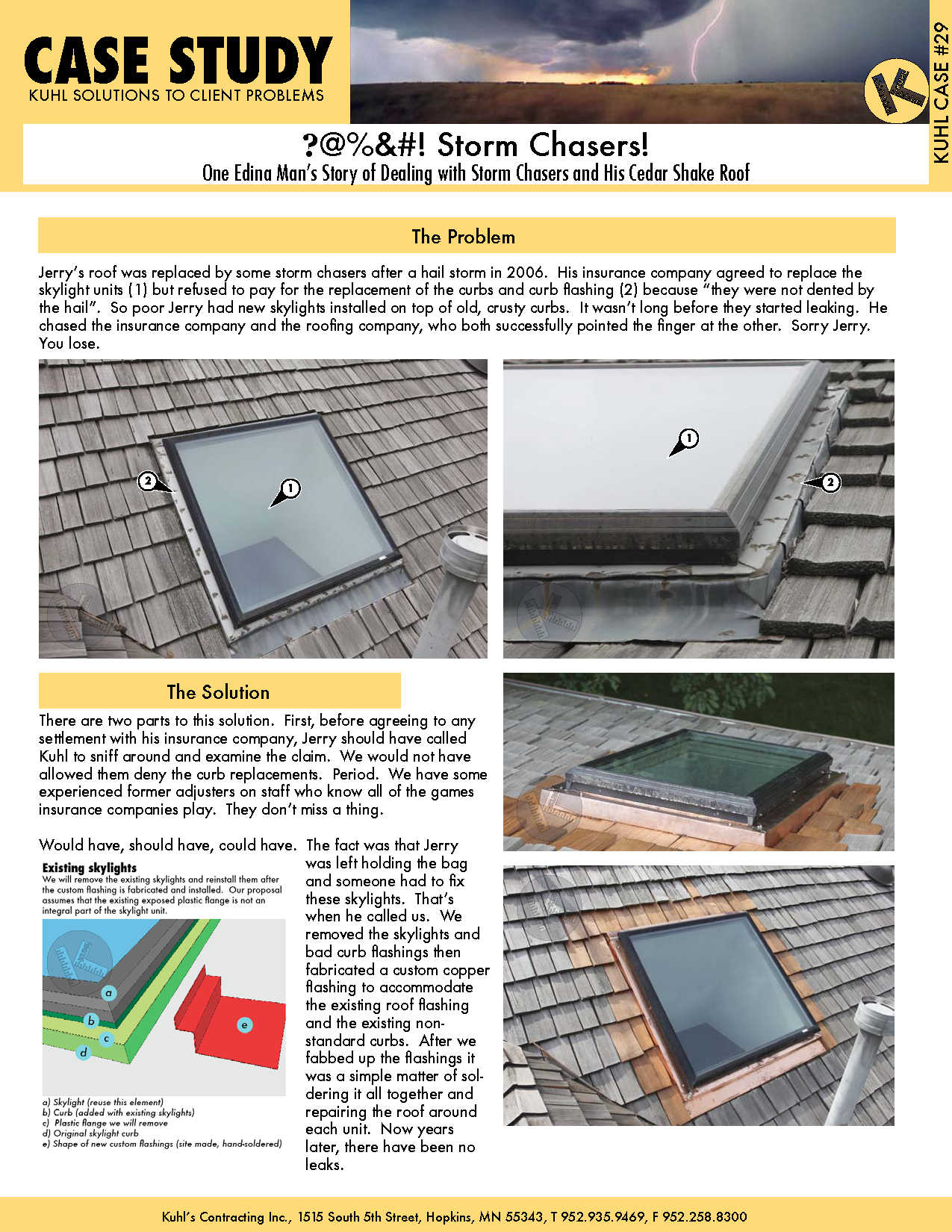

After It Hails It Often Rains Losers: How to Avoid Storm Chasers in Minneapolis

?@%&#! Storm Chasers!

One Edina Man’s Story of Dealing with Storm Chasers and His Cedar Shake Roof

The Problem

Jerry’s roof was replaced by some storm chasers after a hail storm in 2006. His insurance company agreed to replace the

skylight units (1) but refused to pay for the replacement of the curbs and curb flashing (2) because “they were not dented by

the hail”. So poor Jerry had new skylights installed on top of old, crusty curbs. It wasn’t long before they started leaking. He

chased the insurance company and the roofing company, who both successfully pointed the finger at the other. Sorry Jerry.

You lose.

The Solution

There are two parts to this solution. First, before agreeing to any

settlement with his insurance company, Jerry should have called

Kuhl to sniff around and examine the claim. We would not have

allowed them deny the curb replacements. Period. We have some

experienced former adjusters on staff who know all of the games

insurance companies play. They don’t miss a thing.

Would have, should have, could have. The fact was that Jerry

was left holding the bag

and someone had to fix

these skylights. That’s

when he called us. We

removed the skylights and

bad curb flashings then

fabricated a custom copper

flashing to accommodate

the existing roof flashing

and the existing nonstandard

curbs. After we

fabbed up the flashings it

was a simple matter of soldering

it all together and

repairing the roof around

each unit. Now years

later, there have been no

leaks.

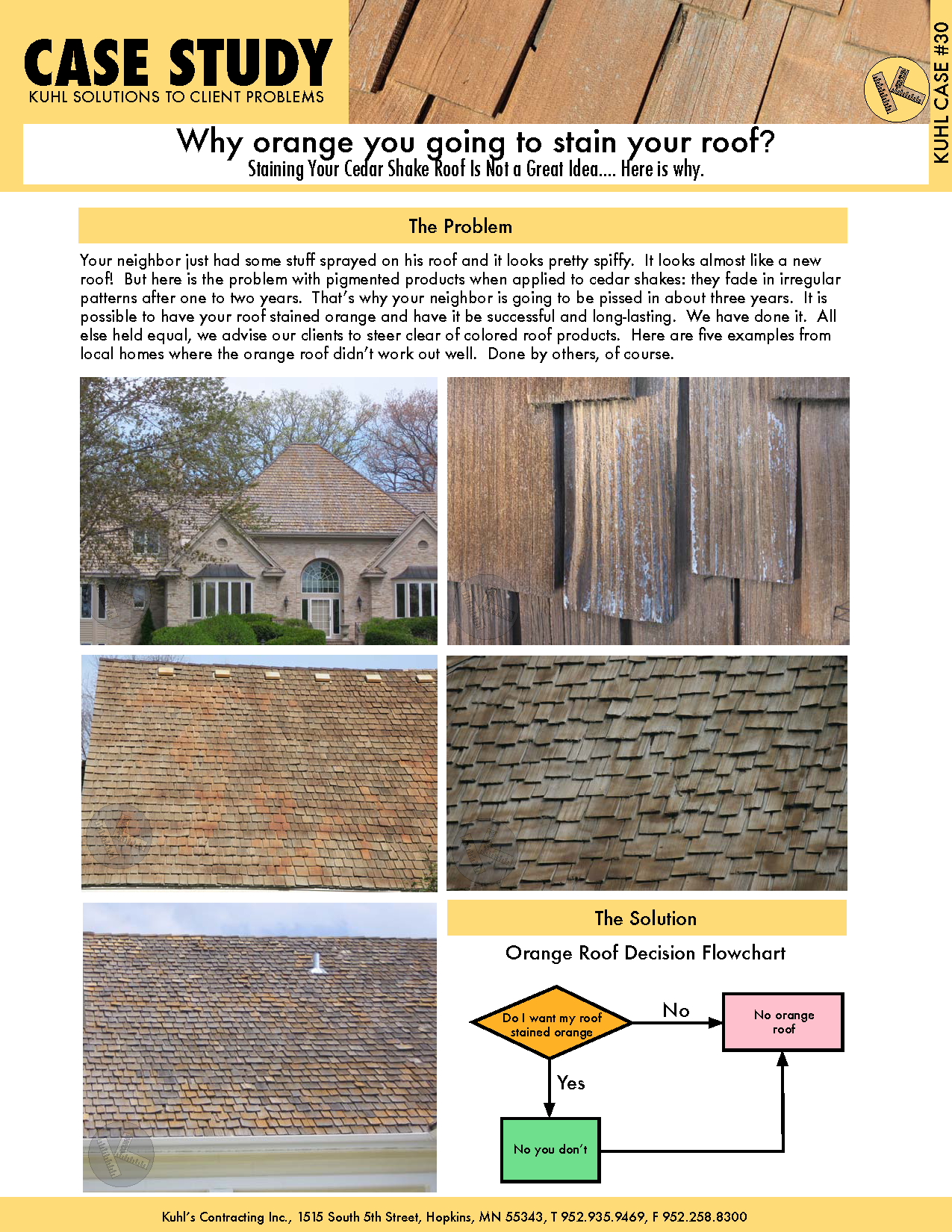

Why orange you going to stain your roof?

Why orange you going to stain your roof?

Staining Your Cedar Shake Roof Is Not a Great Idea…. Here is why.

Your neighbor just had some stuff sprayed on his roof and it looks pretty spiffy. It looks almost like a new

roof! But here is the problem with pigmented products when applied to cedar shakes: they fade in irregular

patterns after one to two years. That’s why your neighbor is going to be pissed in about three years. It is

possible to have your roof stained orange and have it be successful and long-lasting. We have done it. All

else held equal, we advise our clients to steer clear of colored roof products. Here are five examples from

local homes where the orange roof didn’t work out well. Done by others, of course.

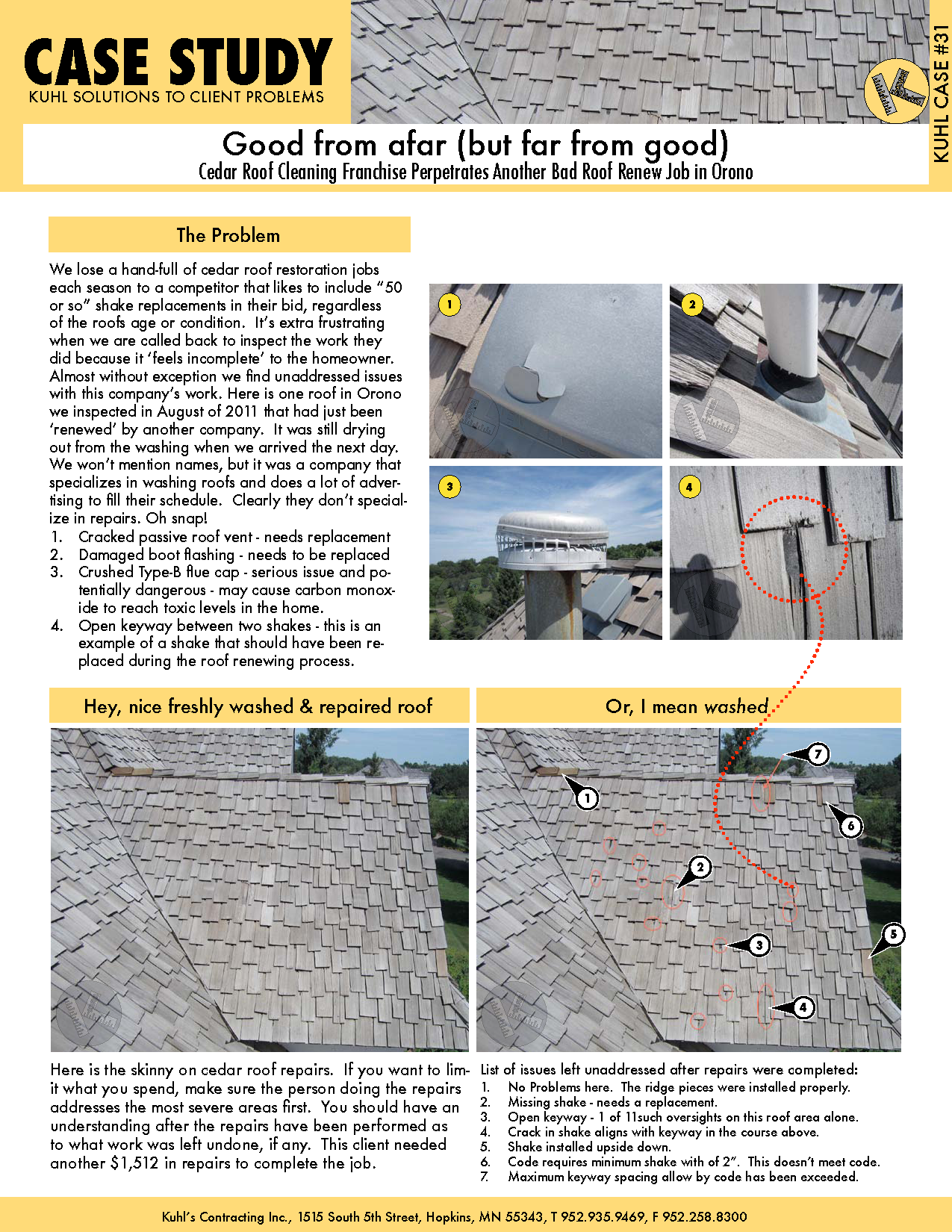

Good From Afar (But Far From Good)

Good from afar (but far from good)

Cedar Roof Cleaning Franchise Perpetrates Another Bad Roof Renew Job in Orono

The Problem

We lose a hand-full of cedar roof restoration jobs

each season to a competitor that likes to include “50

or so” shake replacements in their bid, regardless

of the roofs age or condition. It’s extra frustrating

when we are called back to inspect the work they

did because it ‘feels incomplete’ to the homeowner.

Almost without exception we find unaddressed issues

with this company’s work. Here is one roof in Orono

we inspected in August of 2011 that had just been

‘renewed’ by another company. It was still drying

out from the washing when we arrived the next day.

We won’t mention names, but it was a company that

specializes in washing roofs and does a lot of advertising

to fill their schedule. Clearly they don’t specialize

in repairs. Oh snap!

Here is the skinny on cedar roof repairs. If you want to limit

what you spend, make sure the person doing the repairs

addresses the most severe areas first. You should have an

understanding after the repairs have been performed as

to what work was left undone, if any. This client needed

another $1,512 in repairs to complete the job.

The Problem

Hey, nice freshly washed & repaired roof

1. Cracked passive roof vent – needs replacement

2. Damaged boot flashing – needs to be replaced

3. Crushed Type-B flue cap – serious issue and potentially

dangerous – may cause carbon monoxide

to reach toxic levels in the home.

4. Open keyway between two shakes – this is an

example of a shake that should have been replaced

during the roof renewing process.

List of issues left unaddressed after repairs were completed:

1. No Problems here. The ridge pieces were installed properly.

2. Missing shake – needs a replacement.

3. Open keyway – 1 of 11such oversights on this roof area alone.

4. Crack in shake aligns with keyway in the course above.

5. Shake installed upside down.

6. Code requires minimum shake with of 2”. This doesn’t meet code.

7. Maximum keyway spacing allow by code has been exceeded.

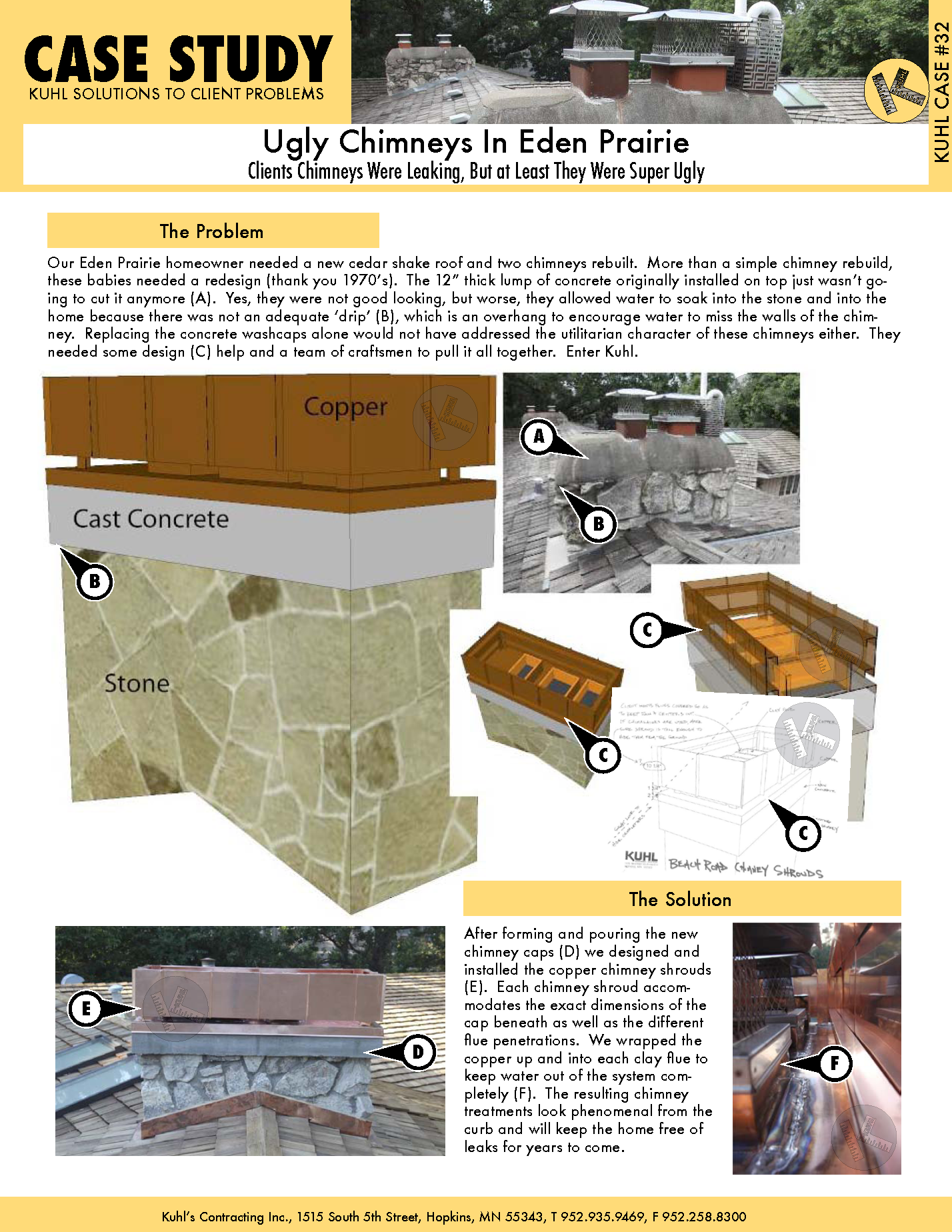

Ugly Chimneys: Custom Metal Chimney Shroud is the Answer

Ugly Chimneys In Eden Prairie

Clients Chimneys Were Leaking, But at Least They Were Super Ugly

The Problem

Our Eden Prairie homeowner needed a new cedar shake roof and two chimneys rebuilt. More than a simple chimney rebuild,

these babies needed a redesign (thank you 1970’s). The 12” thick lump of concrete originally installed on top just wasn’t going

to cut it anymore (A). Yes, they were not good looking, but worse, they allowed water to soak into the stone and into the

home because there was not an adequate ‘drip’ (B), which is an overhang to encourage water to miss the walls of the chimney.

Replacing the concrete washcaps alone would not have addressed the utilitarian character of these chimneys either. They

needed some design (C) help and a team of craftsmen to pull it all together. Enter Kuhl.

The Solution

After forming and pouring the new

chimney caps (D) we designed and

installed the copper chimney shrouds

(E). Each chimney shroud accommodates

the exact dimensions of the

cap beneath as well as the different

flue penetrations. We wrapped the

copper up and into each clay flue to

keep water out of the system completely

(F). The resulting chimney

treatments look phenomenal from the

curb and will keep the home free of

leaks for years to come.

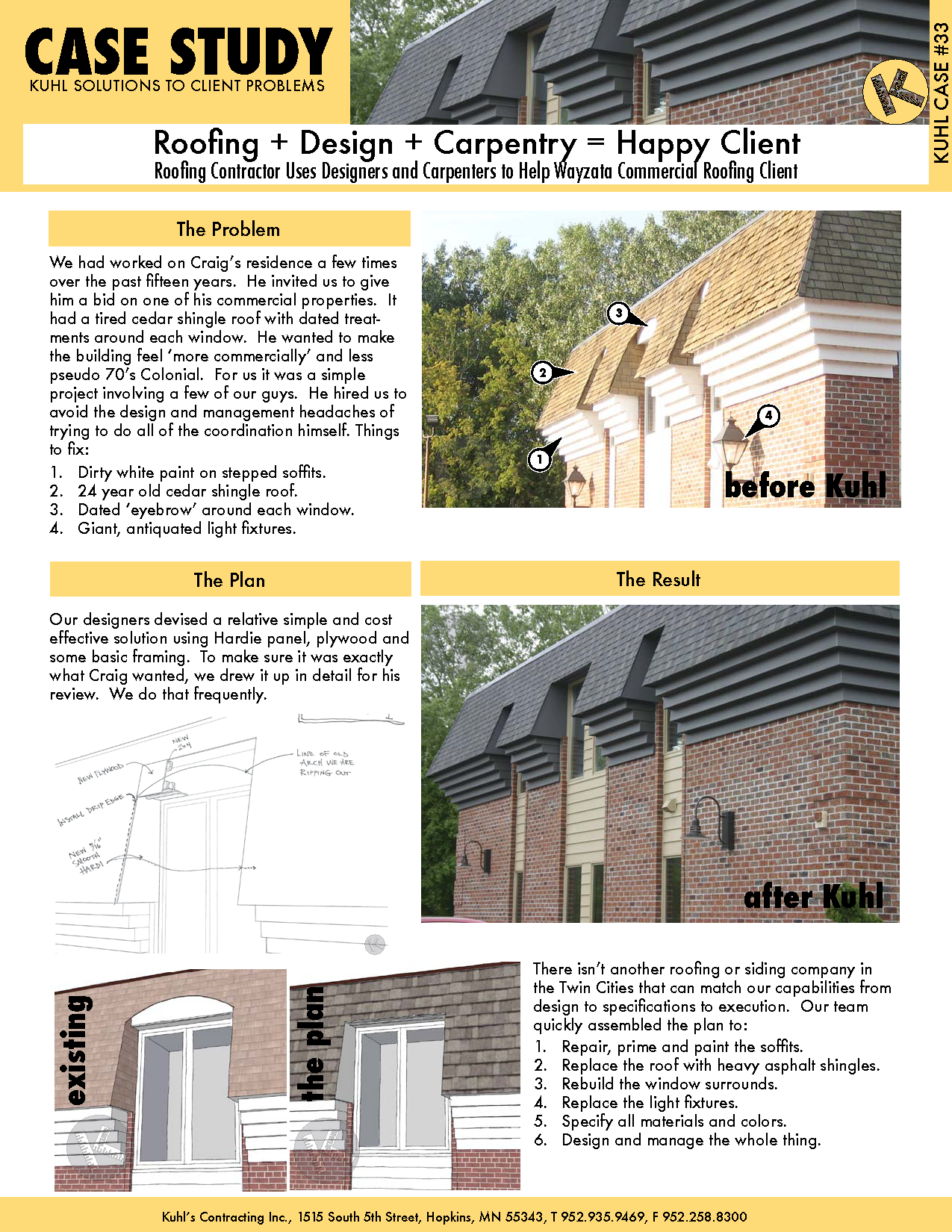

Roofing + Design + Carpentry = Happy Client

Roofing + Design + Carpentry = Happy Client

Roofing Contractor Uses Designers and Carpenters to Help Wayzata Commercial Roofing Client

We had worked on Craig’s residence a few times

over the past fifteen years. He invited us to give

him a bid on one of his commercial properties. It

had a tired cedar shingle roof with dated treatments

around each window. He wanted to make

the building feel ‘more commercially’ and less

pseudo 70’s Colonial. For us it was a simple

project involving a few of our guys. He hired us to

avoid the design and management headaches of

trying to do all of the coordination himself. Things

to fix:

Our designers devised a relative simple and cost

effective solution using Hardie panel, plywood and

some basic framing. To make sure it was exactly

what Craig wanted, we drew it up in detail for his

review. We do that frequently.

There isn’t another roofing or siding company in

the Twin Cities that can match our capabilities from

design to specifications to execution. Our team

quickly assembled the plan to:

The Problem

The Plan The Result

KUHL CASE #33

KUHL SOLUTIONS TO CLIENT PROBLEMS CASE STUDY

1. Dirty white paint on stepped soffits.

2. 24 year old cedar shingle roof.

3. Dated ‘eyebrow’ around each window.

4. Giant, antiquated light fixtures.

1. Repair, prime and paint the soffits.

2. Replace the roof with heavy asphalt shingles.

3. Rebuild the window surrounds.

4. Replace the light fixtures.

5. Specify all materials and colors.

6. Design and manage the whole thing.

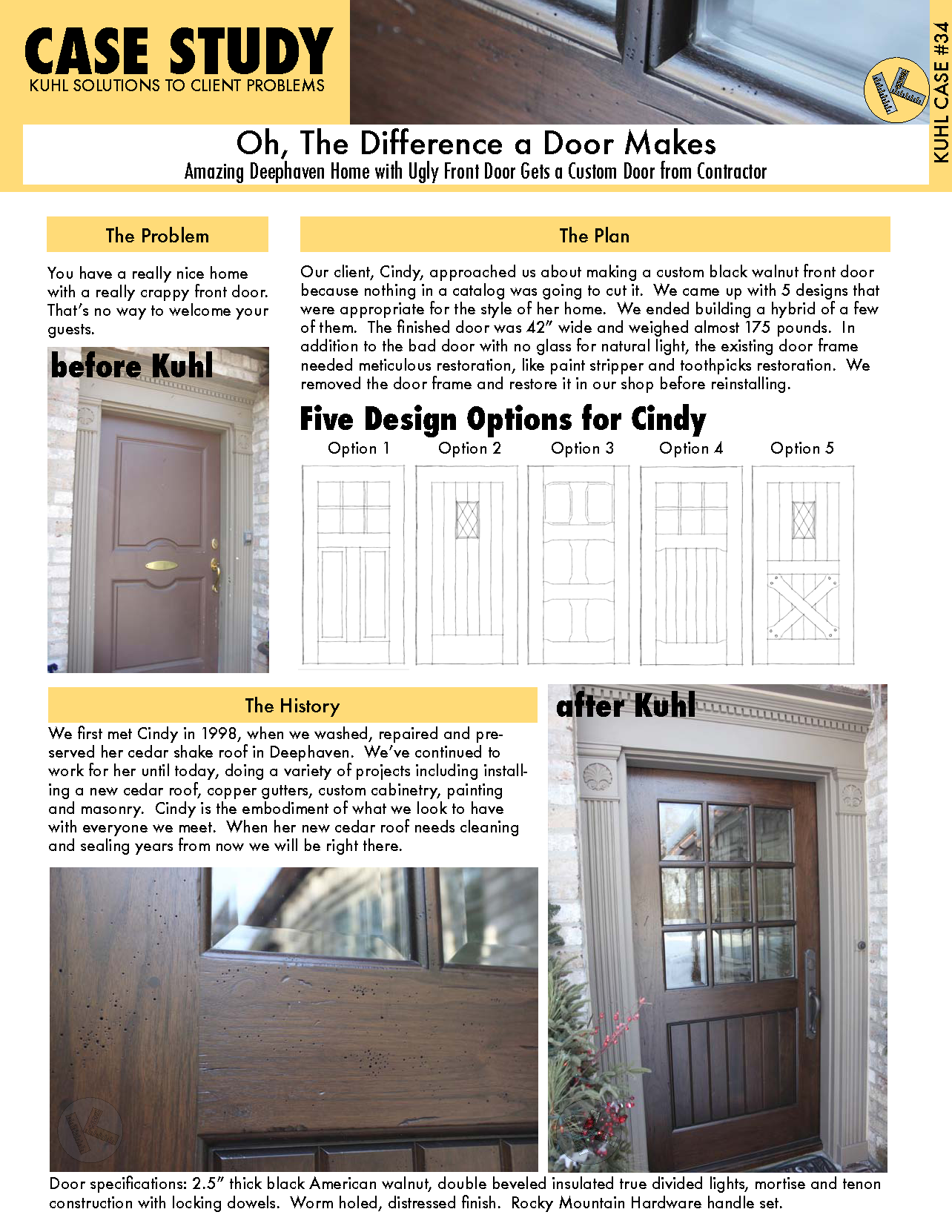

Oh, The Difference a Door Makes: Custom Door for Minneapolis Home

Oh, The Difference a Door Makes

Amazing Deephaven Home with Ugly Front Door Gets a Custom Door from Contractor

The Problem

You have a really nice home

with a really crappy front door.

That’s no way to welcome your

guests.

The Plan

Our client, Cindy, approached us about making a custom black walnut front door

because nothing in a catalog was going to cut it. We came up with 5 designs that

were appropriate for the style of her home. We ended building a hybrid of a few

of them. The finished door was 42” wide and weighed almost 175 pounds. In

addition to the bad door with no glass for natural light, the existing door frame

needed meticulous restoration, like paint stripper and toothpicks restoration. We

removed the door frame and restore it in our shop before reinstalling.

The History

We first met Cindy in 1998, when we washed, repaired and preserved

her cedar shake roof in Deephaven. We’ve continued to

work for her until today, doing a variety of projects including installing

a new cedar roof, copper gutters, custom cabinetry, painting

and masonry. Cindy is the embodiment of what we look to have

with everyone we meet. When her new cedar roof needs cleaning

and sealing years from now we will be right there.

Door specifications: 2.5” thick black American walnut, double beveled insulated true divided lights, mortise and tenon

construction with locking dowels. Worm holed, distressed finish. Rocky Mountain Hardware handle set.

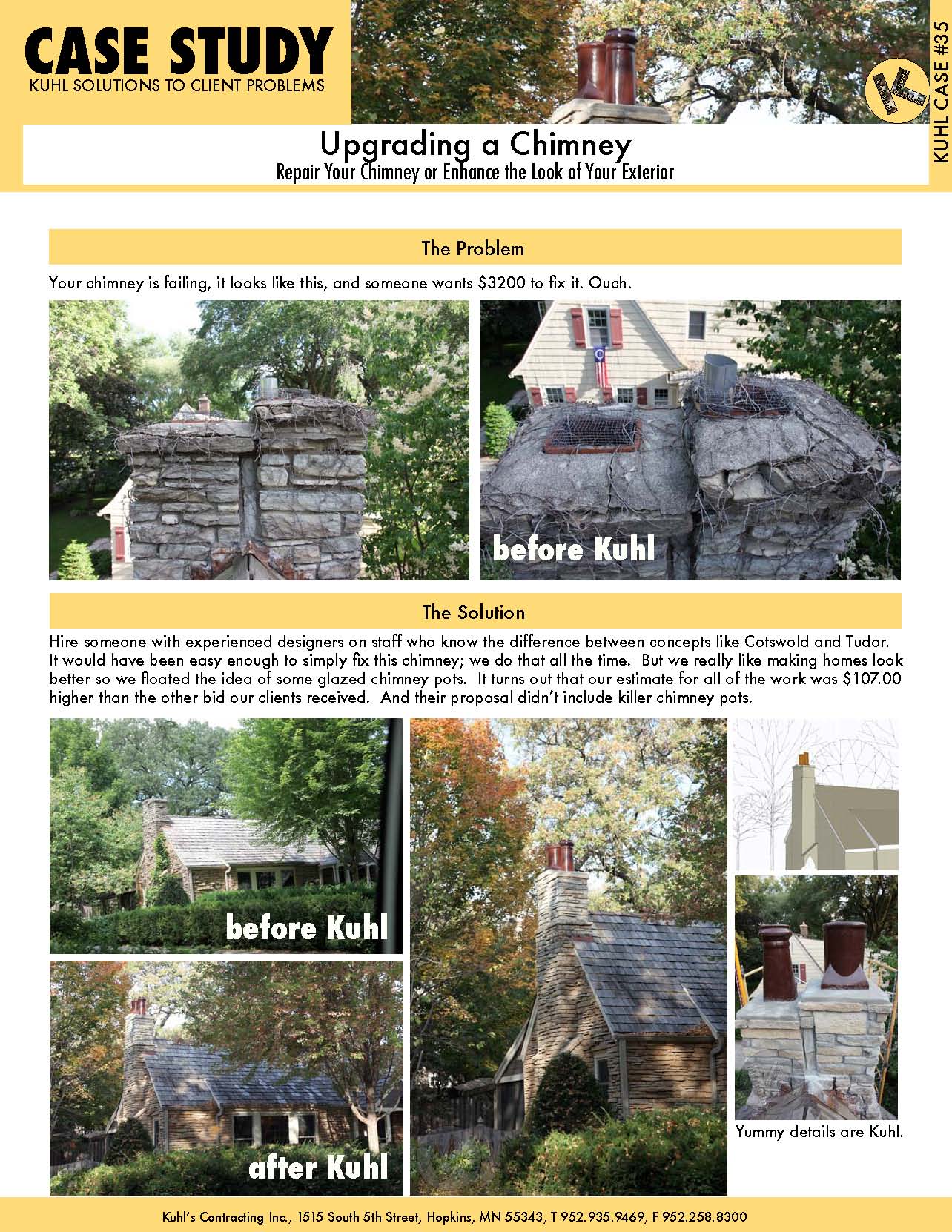

Upgrading a Chimney: Chimney Repair In Edina

Upgrading a Chimney

Repair Your Chimney or Enhance the Look of Your Exterior

The Problem

Your chimney is failing, it looks like this, and someone wants $3200 to fix it. Ouch.

The Solution

Hire someone with experienced designers on staff who know the difference between concepts like Cotswold and Tudor.

It would have been easy enough to simply fix this chimney; we do that all the time. But we really like making homes look

better so we floated the idea of some glazed chimney pots. It turns out that our estimate for all of the work was $107.00

higher than the other bid our clients received. And their proposal didn’t include killer chimney pots.

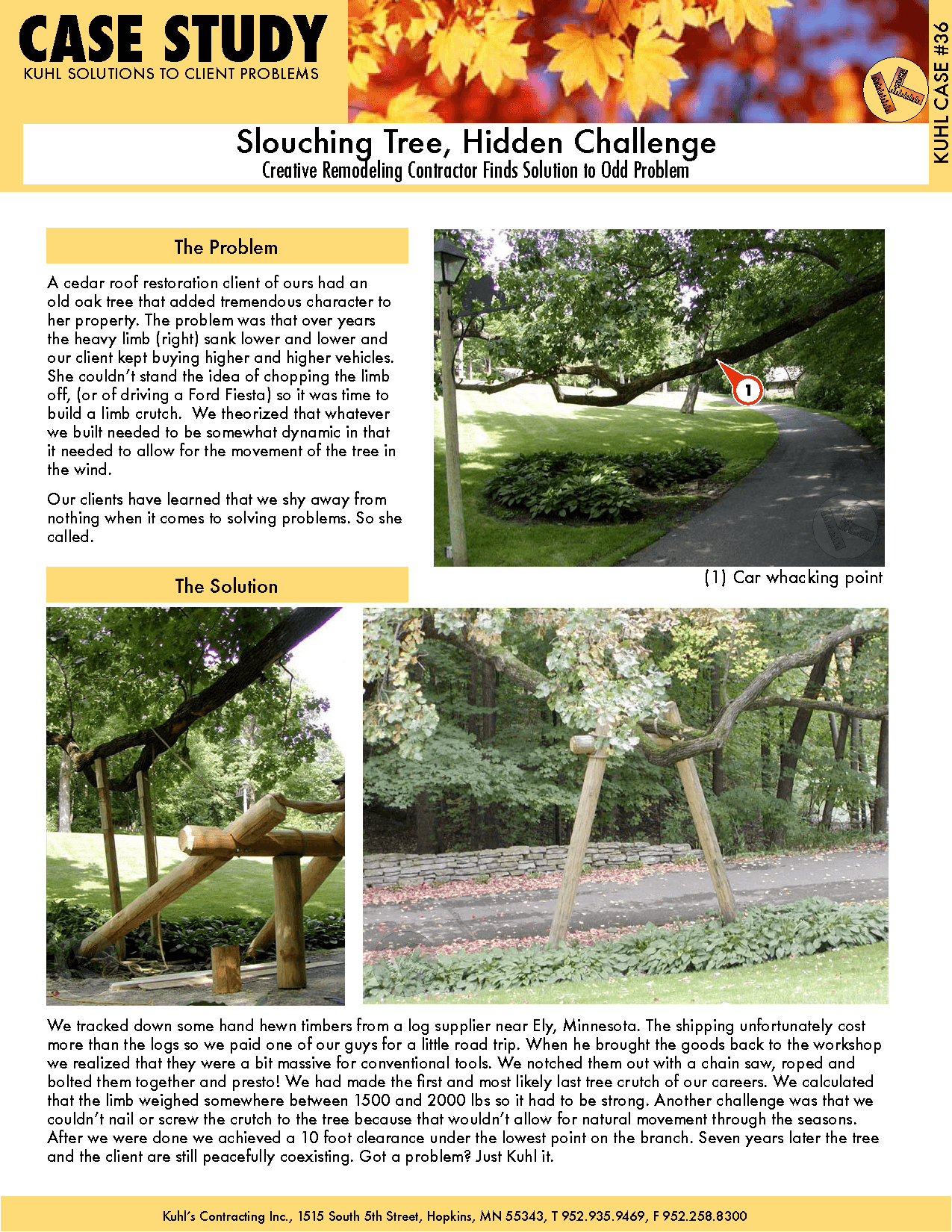

Small Random Handyman Job in Deephaven

Slouching Tree, Hidden Challenge

Creative Remodeling Contractor Finds Solution to Odd Problem

A cedar roof restoration client of ours had an

old oak tree that added tremendous character to

her property. The problem was that over years

the heavy limb (right) sank lower and lower and

our client kept buying higher and higher vehicles.

She couldn’t stand the idea of chopping the limb

off, (or of driving a Ford Fiesta) so it was time to

build a limb crutch. We theorized that whatever

we built needed to be somewhat dynamic in that

it needed to allow for the movement of the tree in

the wind.

(1) Car whacking point

We tracked down some hand hewn timbers from a log supplier near Ely, Minnesota. The shipping unfortunately cost

more than the logs so we paid one of our guys for a little road trip. When he brought the goods back to the workshop we realized that they were a bit massive for conventional tools. We notched them out with a chain saw, roped and bolted them together and presto! We had made the first and most likely last tree crutch of our careers. We calculated

that the limb weighed somewhere between 1500 and 2000 lbs so it had to be strong. Another challenge was that we

couldn’t nail or screw the crutch to the tree because that wouldn’t allow for natural movement through the seasons.

After we were done we achieved a 10 foot clearance under the lowest point on the branch. Seven years later the tree

and the client are still peacefully coexisting. Got a problem? Just Kuhl it.

The Problem

The Solution

Our clients have learned that we shy away from

nothing when it comes to solving problems. So she

called.

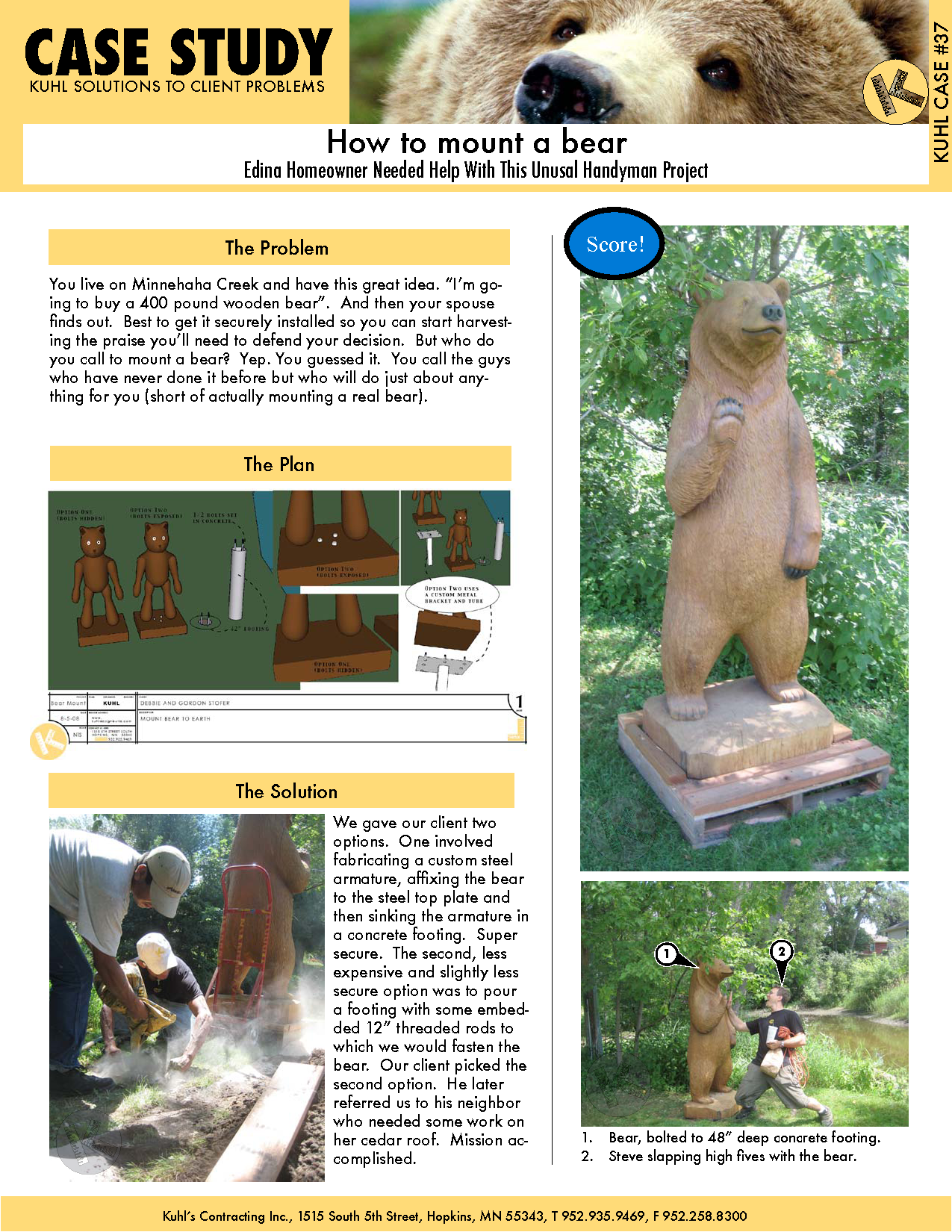

Small Handyman Jobs in Minneapolis: No Job Too Small (Or Bizarre)

The Problem

You live on Minnehaha Creek and have this great idea. “I’m go- ing to buy a 400 pound wooden bear”. And then your spouse finds out. Best to get it securely installed so you can start harvest- ing the praise you’ll need to defend your decision. But who do you call to mount a bear? Yep. You guessed it. You call the guys who have never done it before but who will do just about any- thing for you (short of actually mounting a real bear).

The Solution

We gave our client two options. One involved fabricating a custom steel armature, affixing the bear to the steel top plate and then sinking the armature in a concrete footing. Super secure. The second, less expensive and slightly less secure option was to pour a footing with some embed- ded 12” threaded rods to which we would fasten the bear. Our client picked the second option. He later referred us to his neighbor who needed some work on her cedar roof. Mission ac- complished.

Honest Minneapolis Roof Restoration Company Calls It Like It Is. No, Seriously.

Hear. See. Speak. We’ll tell you what we find.

Minnetonka Homeowner Hears the Truth from Roof Cleaning Contractor with Integrity

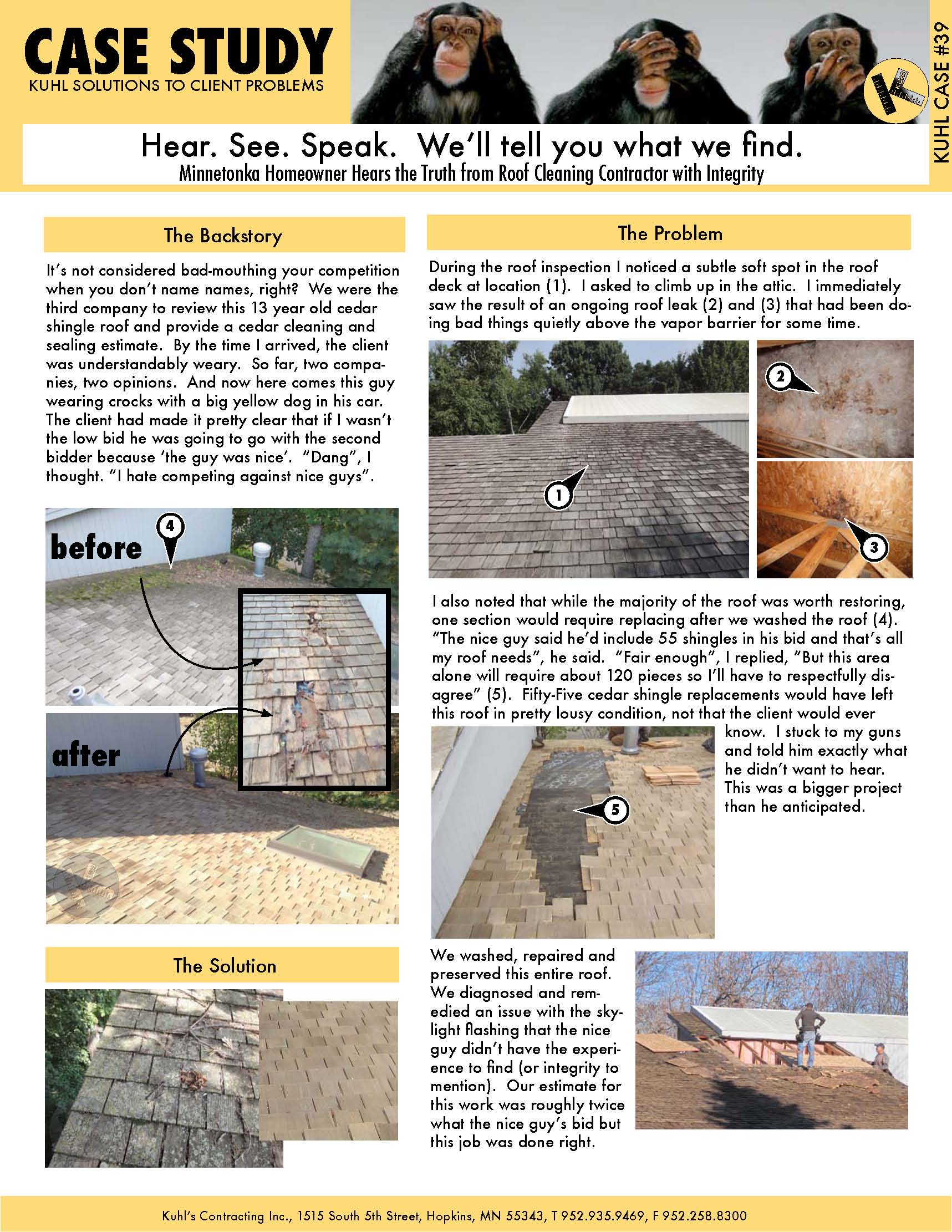

The Backstory

It’s not considered bad-mouthing your competition

when you don’t name names, right? We were the

third company to review this 13 year old cedar

shingle roof and provide a cedar cleaning and

sealing estimate. By the time I arrived, the client

was understandably weary. So far, two companies,

two opinions. And now here comes this guy

wearing crocks with a big yellow dog in his car.

The client had made it pretty clear that if I wasn’t

the low bid he was going to go with the second

bidder because ‘the guy was nice’. “Dang”, I

thought. “I hate competing against nice guys”.

The Problem

During the roof inspection I noticed a subtle soft spot in the roof

deck at location (1). I asked to climb up in the attic. I immediately

saw the result of an ongoing roof leak (2) and (3) that had been doing

bad things quietly above the vapor barrier for some time.

I also noted that while the majority of the roof was worth restoring,

one section would require replacing after we washed the roof (4).

“The nice guy said he’d include 55 shingles in his bid and that’s all

my roof needs”, he said. “Fair enough”, I replied, “But this area

alone will require about 120 pieces so I’ll have to respectfully disagree”

(5). Fifty-Five cedar shingle replacements would have left

this roof in pretty lousy condition, not that the client would ever

know. I stuck to my guns

and told him exactly what

he didn’t want to hear.

This was a bigger project

than he anticipated.

We washed, repaired and

preserved this entire roof.

We diagnosed and remedied

an issue with the skylight

flashing that the nice

guy didn’t have the experience

to find (or integrity to

mention). Our estimate for

this work was roughly twice

what the nice guy’s bid but

this job was done right.

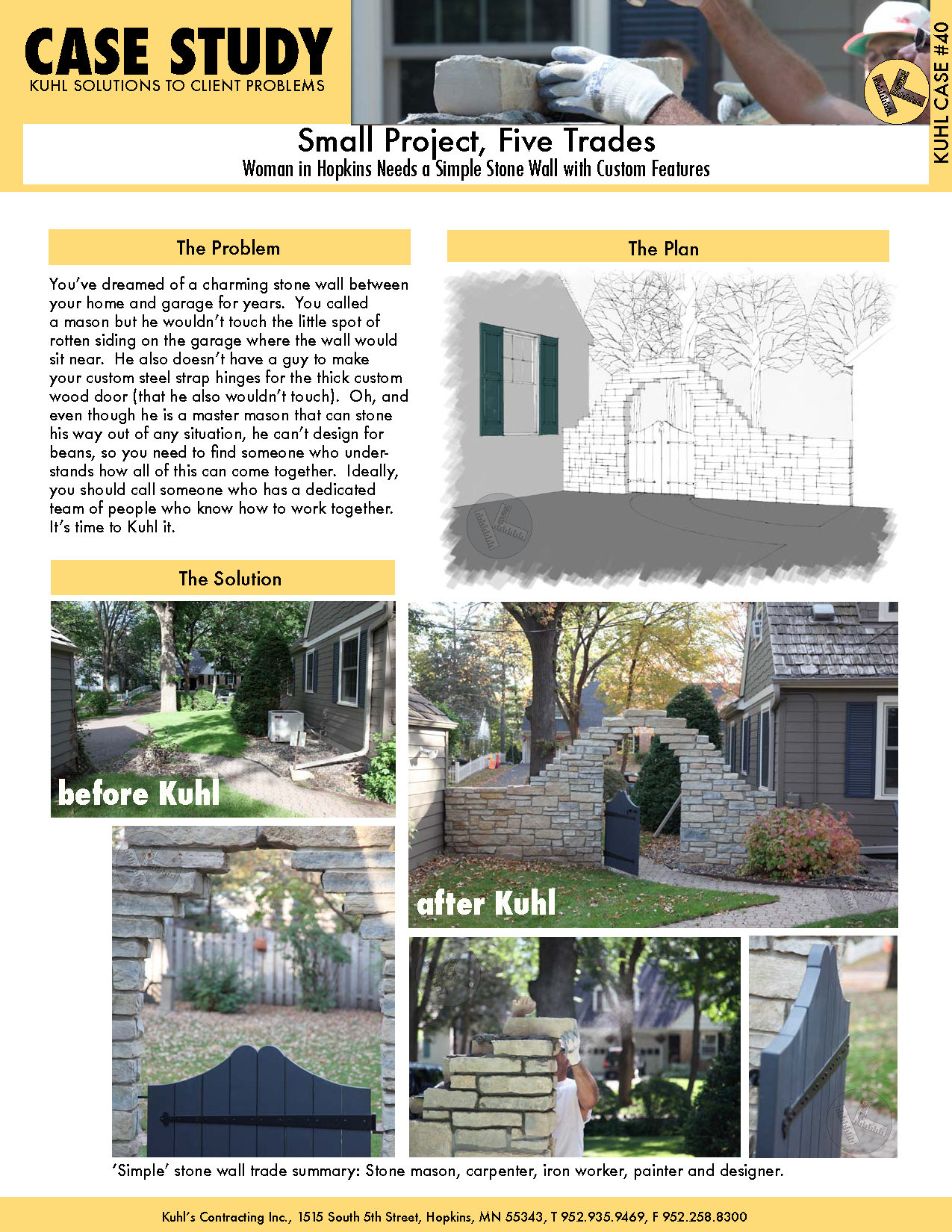

Small Project, Five Trades: Dealing with Small Custom Projects

Small Project, Five Trades

Woman in Hopkins Needs a Simple Stone Wall with Custom Features

The problem

You’ve dreamed of a charming stone wall between

your home and garage for years. You called

a mason but he wouldn’t touch the little spot of

rotten siding on the garage where the wall would

sit near. He also doesn’t have a guy to make

your custom steel strap hinges for the thick custom

wood door (that he also wouldn’t touch). Oh, and

even though he is a master mason that can stone

his way out of any situation, he can’t design for

beans, so you need to find someone who understands

how all of this can come together. Ideally,

you should call someone who has a dedicated

team of people who know how to work together.

It’s time to Kuhl it.

‘Simple’ stone wall trade summary: Stone mason, carpenter, iron worker, painter and designer.

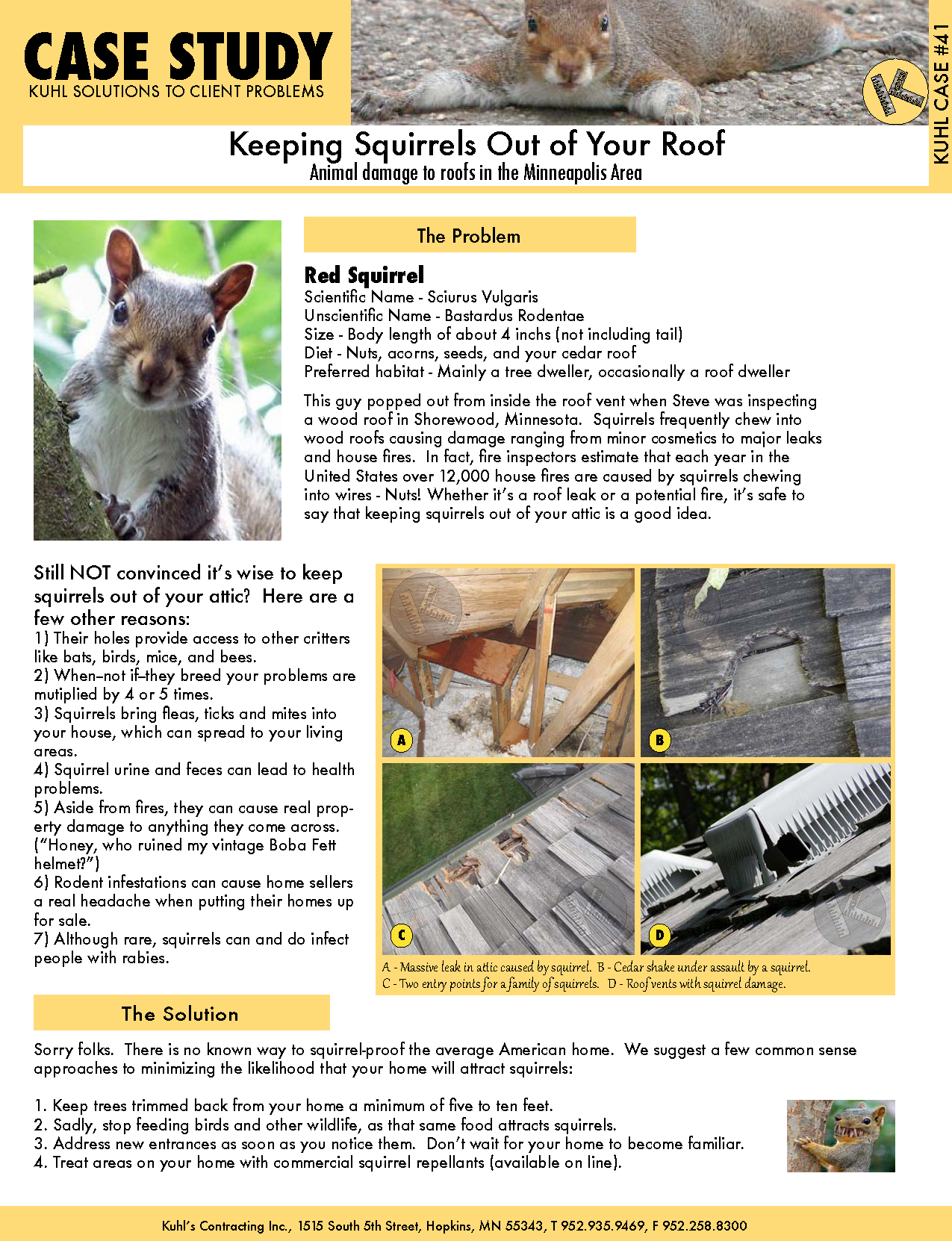

Keeping Squirrels Out of Your Roof: Animal Damage Tips

Keeping Squirrels Out of Your Roof: Animal Damage to Roofs In The Minneapolis Area

Case 41

Red Squirrel

Scientific Name – Sciurus Vulgaris

Unscientific Name – Bastardus Rodentae

Size – Body length of about 4 inchs (not including tail)

Diet – Nuts, acorns, seeds, and your cedar roof

Preferred habitat – Mainly a tree dweller, occasionally a roof dweller

Kuhl’s Contracting Inc., 1515 South 5th Street, Hopkins, MN 55343, T 952.935.9469, F 952.258.8300

KUHL SOLUTIONS TO CLIENT PROBLEMS CASE STUDY

KUHL CASE #41

The Problem

The Solution

Still NOT convinced it’s wise to keep

squirrels out of your attic? Here are a

few other reasons:

1) Their holes provide access to other critters

like bats, birds, mice, and bees.

2) When–not if–they breed your problems are

mutiplied by 4 or 5 times.

3) Squirrels bring fleas, ticks and mites into

your house, which can spread to your living

areas.

4) Squirrel urine and feces can lead to health

problems.

5) Aside from fires, they can cause real property

damage to anything they come across.

(“Honey, who ruined my vintage Boba Fett

helmet?”)

6) Rodent infestations can cause home sellers

a real headache when putting their homes up

for sale.

7) Although rare, squirrels can and do infect

people with rabies.

This guy popped out from inside the roof vent when Steve was inspecting

a wood roof in Shorewood, Minnesota. Squirrels frequently chew into

wood roofs causing damage ranging from minor cosmetics to major leaks

and house fires. In fact, fire inspectors estimate that each year in the

United States over 12,000 house fires are caused by squirrels chewing

into wires – Nuts! Whether it’s a roof leak or a potential fire, it’s safe to

say that keeping squirrels out of your attic is a good idea.

Sorry folks. There is no known way to squirrel-proof the average American home. We suggest a few common sense

approaches to minimizing the likelihood that your home will attract squirrels:

1. Keep trees trimmed back from your home a minimum of five to ten feet.

2. Sadly, stop feeding birds and other wildlife, as that same food attracts squirrels.

3. Address new entrances as soon as you notice them. Don’t wait for your home to become familiar.

4. Treat areas on your home with commercial squirrel repellants (available on line).

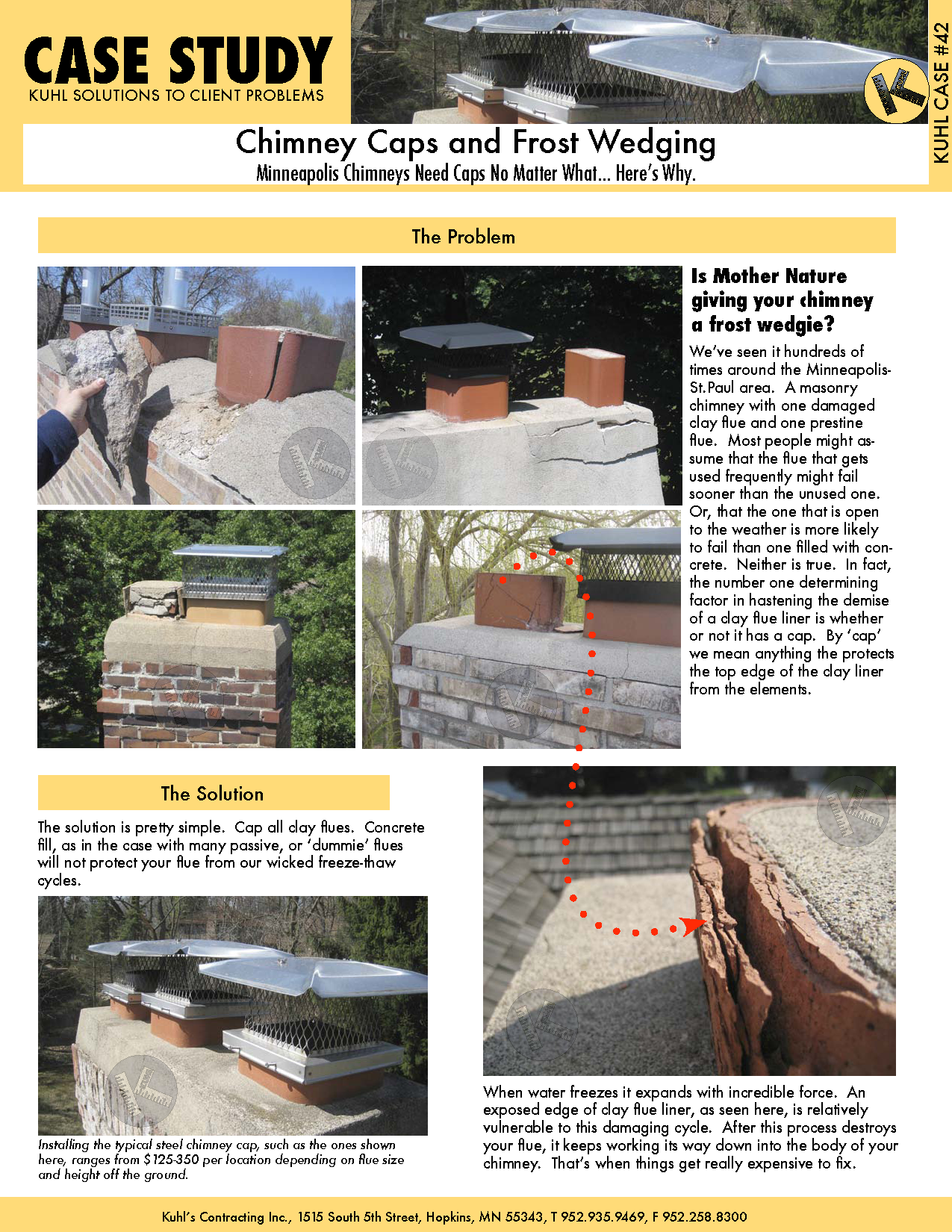

Chimney Caps & Frost Wedging: Minneapolis Chimney Repair Tips

CASE STUDY

Chimney Caps and Frost Wedging

Minneapolis Chimneys Need Caps No Matter What… Here’s Why.

We’ve seen it hundreds of

times around the Minneapolis-

St.Paul area. A masonry

chimney with one damaged

clay flue and one prestine

flue. Most people might assume

that the flue that gets

used frequently might fail

sooner than the unused one.

Or, that the one that is open

to the weather is more likely

to fail than one filled with concrete.

Neither is true. In fact,

the number one determining

factor in hastening the demise

of a clay flue liner is whether

or not it has a cap. By ‘cap’

we mean anything the protects

the top edge of the clay liner

from the elements.

The solution is pretty simple. Cap all clay flues. Concrete

fill, as in the case with many passive, or ‘dummie’ flues

will not protect your flue from our wicked freeze-thaw

cycles.

Is Mother Nature

giving your chimney

a frost wedgie?

Installing the typical steel chimney cap, such as the ones shown

here, ranges from $125-350 per location depending on flue size

and height off the ground.

When water freezes it expands with incredible force. An

exposed edge of clay flue liner, as seen here, is relatively

vulnerable to this damaging cycle. After this process destroys

your flue, it keeps working its way down into the body of your

chimney. That’s when things get really expensive to fix.

KUHL CASE #42

The Solution

Animals in Minneapolis Roof Vents (Part 1): How to Keep Critters Out of Your Home

CASE STUDY

Animals in Minneapolis Roof Vents (Part 1)

How to Keep Birds, Bats, Mice and Squirrels Out of Your Home

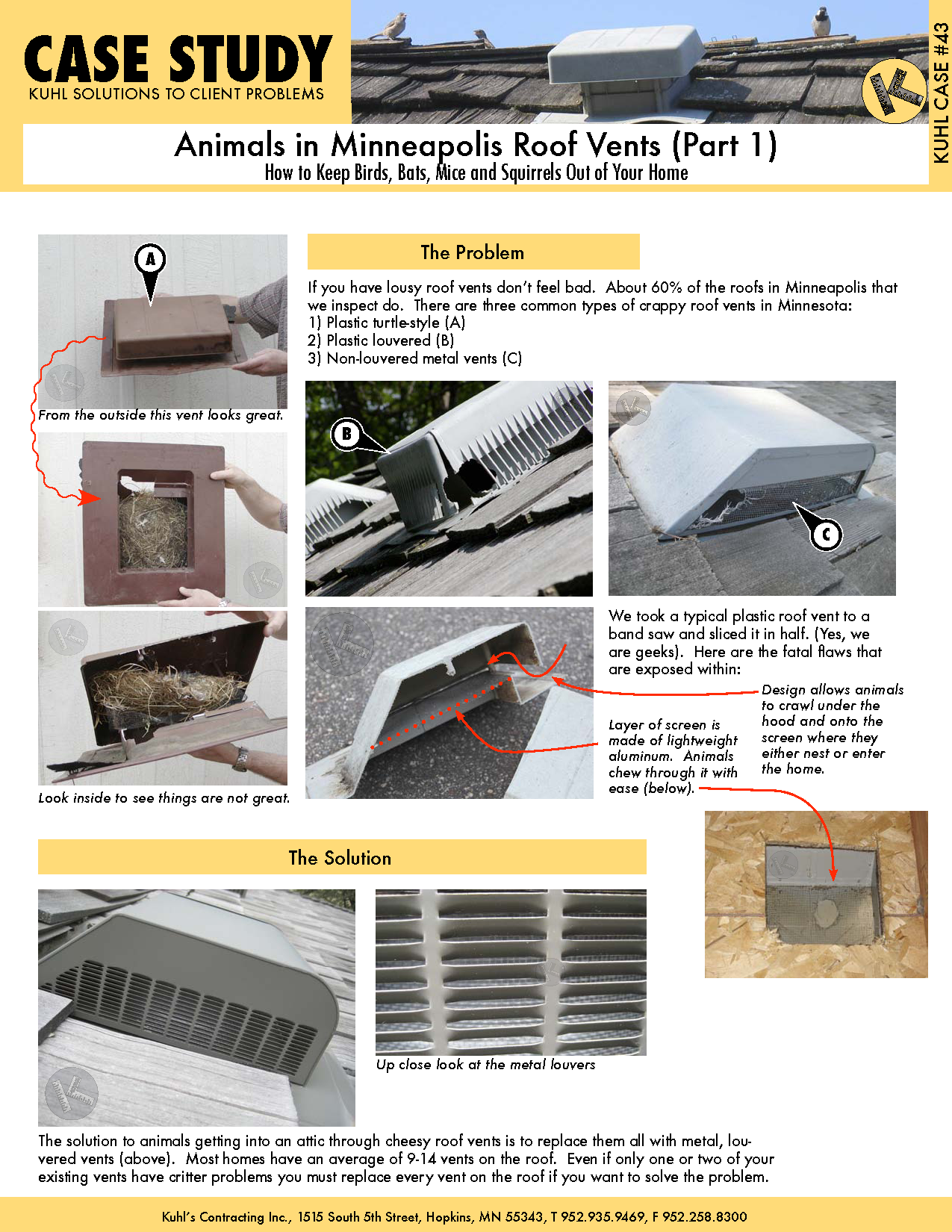

If you have lousy roof vents don’t feel bad. About 60% of the roofs in Minneapolis that

we inspect do. There are three common types of crappy roof vents in Minnesota:

1) Plastic turtle-style (A)

2) Plastic louvered (B)

3) Non-louvered metal vents (C)

From the outside this vent looks great.

Look inside to see things are not great.

Layer of screen is

made of lightweight

aluminum. Animals

chew through it with

ease (below).

Design allows animals

to crawl under the

hood and onto the

screen where they

either nest or enter

the home.

A

C

B

The solution to animals getting into an attic through cheesy roof vents is to replace them all with metal, louvered

vents (above). Most homes have an average of 9-14 vents on the roof. Even if only one or two of your

existing vents have critter problems you must replace every vent on the roof if you want to solve the problem.

We took a typical plastic roof vent to a

band saw and sliced it in half. (Yes, we

are geeks). Here are the fatal flaws that

are exposed within:

Up close look at the metal louvers

Roof Snow Removal In Minneapolis

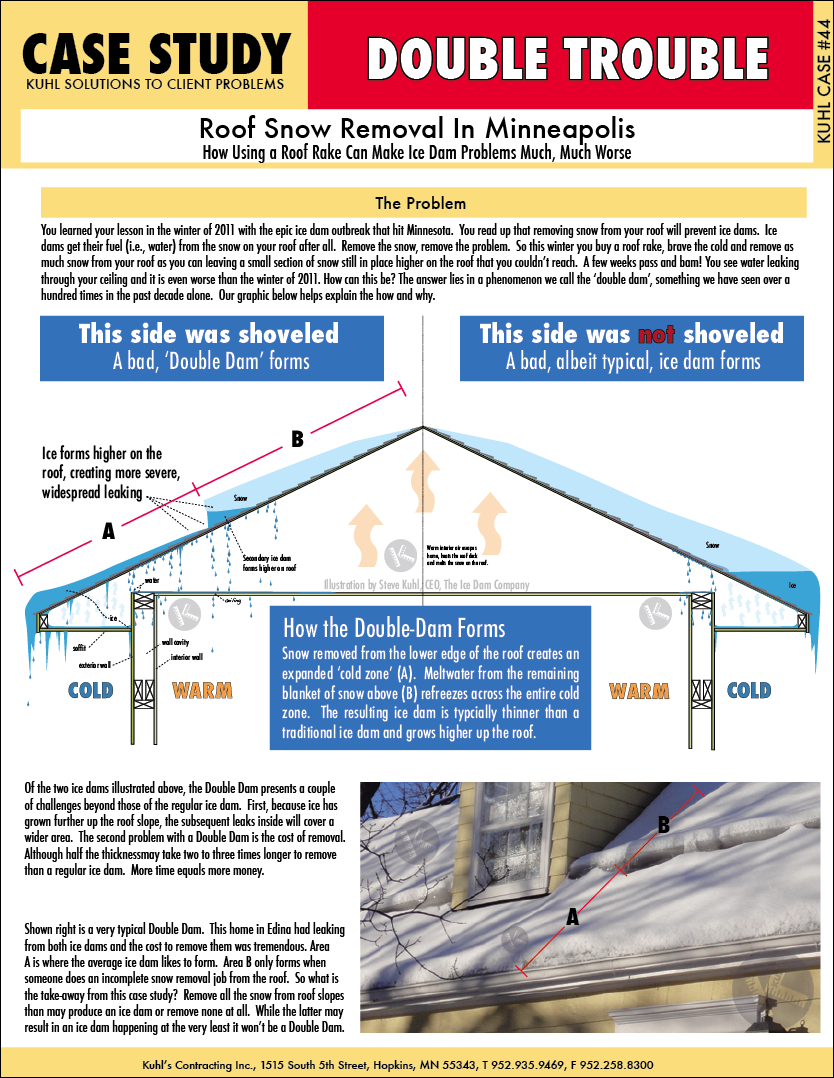

You learned your lesson in the winter of 2011 with the epic ice dam outbreak that hit Minnesota. You read up that removing snow from your roof will prevent ice dams. Ice dams get their fuel (i.e., water) from the snow on your roof after all. Remove the snow, remove the problem. So this winter you buy a roof rake, brave the cold and remove as much snow from your roof as you can leaving a small section of snow still in place higher on the roof that you couldn’t reach. A few weeks pass and bam! You see water leaking through your ceiling and it is even worse than the winter of 2011. How can this be? The answer lies in a phenomenon we call the ‘double dam’, something we have seen over a hundred times in the past decade alone. Our graphic below helps explain the how and why.

Of the two ice dams illustrated above, the Double Dam presents a couple of challenges beyond those of the regular ice dam. First, because ice has grown further up the roof slope, the subsequent leaks inside will cover a wider area. The second problem with a Double Dam is the cost of removal. Although half the thicknessmay take two to three times longer to remove than a regular ice dam. More time equals more money.

hown right is a very typical Double Dam. This home in Edina had leaking from both ice dams and the cost to remove them was tremendous. Area

A is where the average ice dam likes to form. Area B only forms when someone does an incomplete snow removal job from the roof. So what is the take-away from this case study? Remove all the snow from roof slopes than may produce an ice dam or remove none at all. While the latter may result in an ice dam happening at the very least it won’t be a Double Dam.

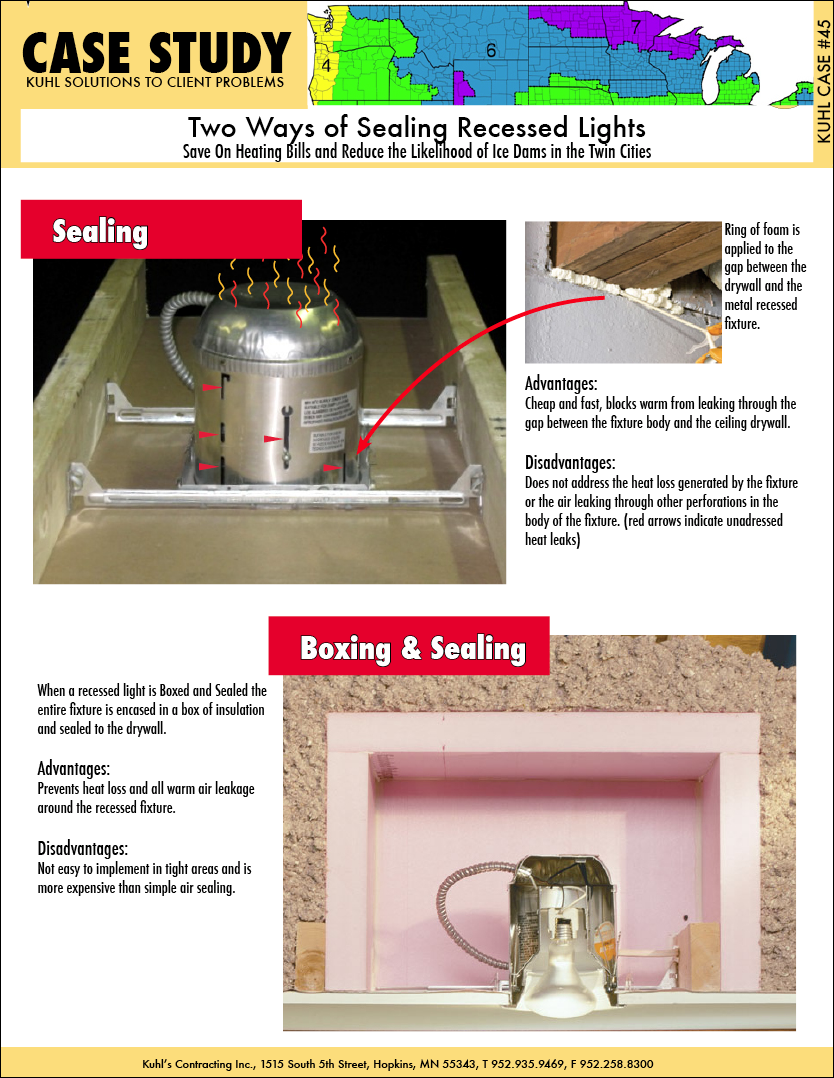

Two Ways of Sealing Recessed Lights

Ring of foam is applied to the gap between the drywall and the metal recessed fixture.

Advantages:

Cheap and fast, blocks warm from leaking through the gap between the fixture body and the ceiling drywall.

Disadvantages:

Does not address the heat loss generated by the fixture or the air leaking through other perforations in the body of the fixture. (red arrows indicate unadressed heat leaks)

When a recessed light is Boxed and Sealed the entire fixture is encased in a box of insulation and sealed to the drywall.

Advantages:

Prevents heat loss and all warm air leakage around the recessed fixture.

Disadvantages:

Not easy to implement in tight areas and is more expensive than simple air sealing.

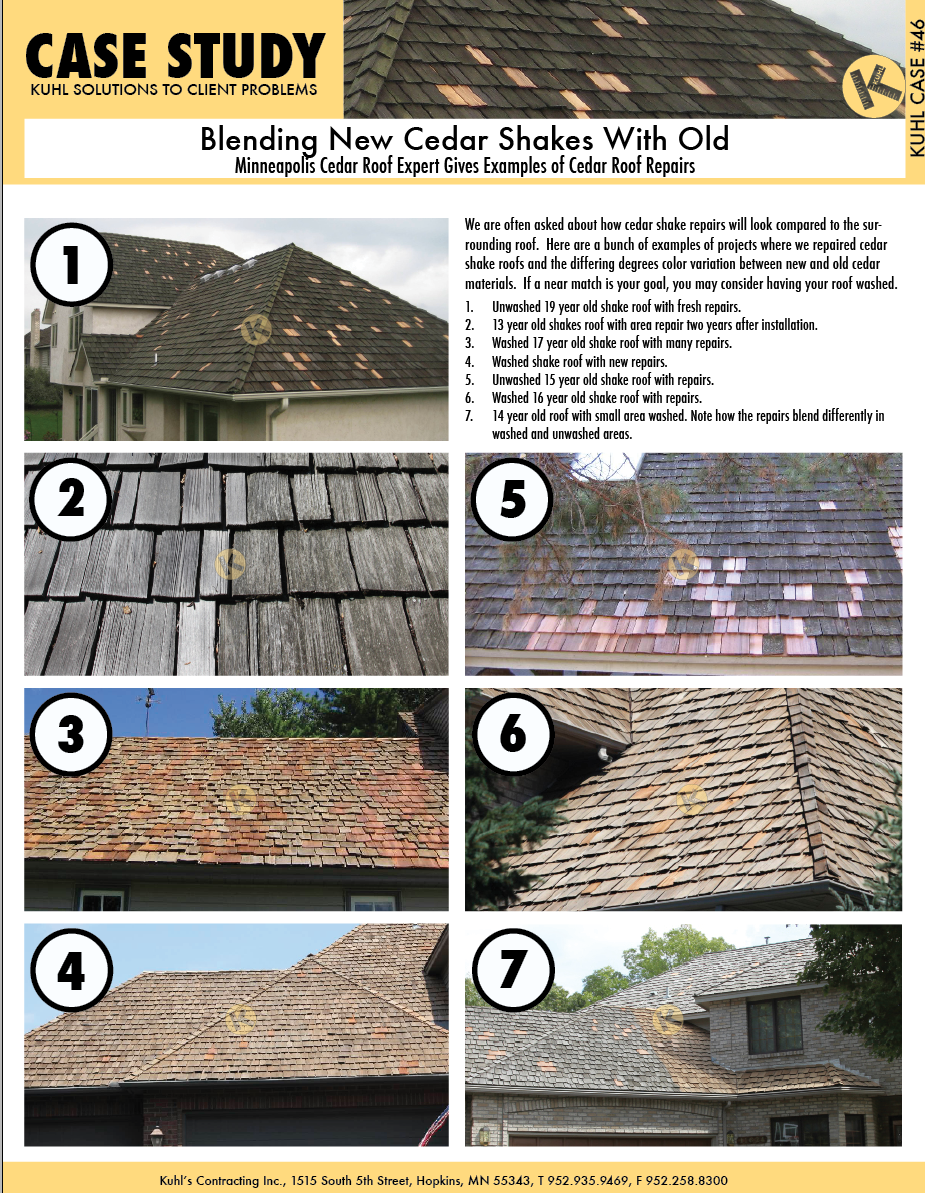

Minneapolis Cedar Roof Expert Gives Examples of Cedar Roof Repairs

We are often asked about how cedar shake repairs will look compared to the sur- rounding roof. Here are a bunch of examples of projects where we repaired cedar shake roofs and the differing degrees color variation between new and old cedar materials. If a near match is your goal, you may consider having your roof washed.

- Unwashed 19 year old shake roof with fresh repairs.

- 13 year old shakes roof with area repair two years after installation.

- Washed 17 year old shake roof with many repairs.

- Washed shake roof with new repairs.

- Unwashed 15 year old shake roof with repairs.

- Washed 16 year old shake roof with repairs.

- 14 year old roof with small area washed. Note how the repairs blend differently in washed and unwashed areas.

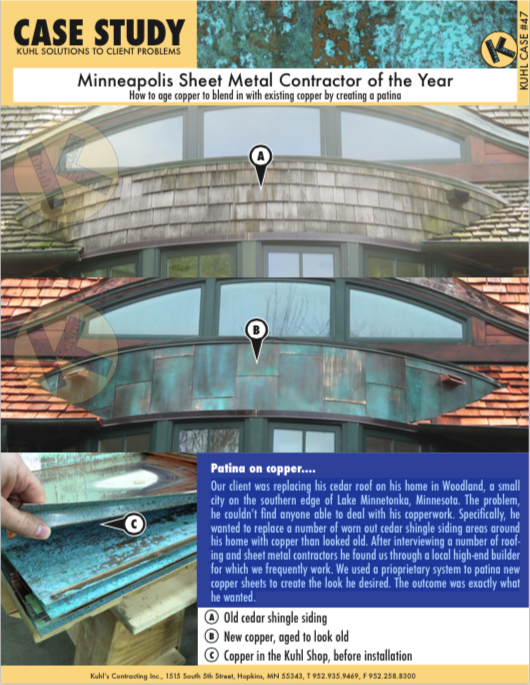

How to age copper to blend in with existing copper by creating a patina

Our client was replacing his cedar roof on his home in Woodland, a small city on the southern edge of Lake Minnetonka, Minnesota. The problem, he couldn’t find anyone able to deal with his copperwork. Specifically, he wanted to replace a number of worn out cedar shingle siding areas around his home with copper than looked old. After interviewing a number of roof- ing and sheet metal contractors he found us through a local high-end builder for which we frequently work. We used a prioprietary system to patina new copper sheets to create the look he desired. The outcome was exactly what he wanted.

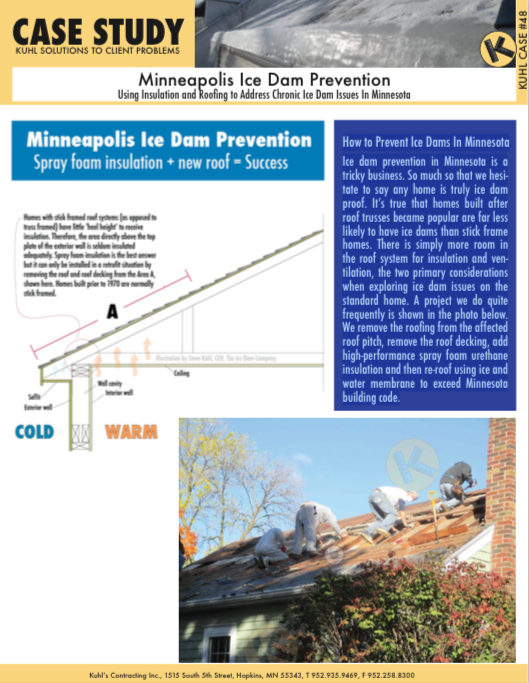

Using Insulation and Roofing to Address Chronic Ice Dam Issues In Minnesota

How to Prevent Ice Dams In Minnesota

Ice dam prevention in Minnesota is a tricky business. So much so that we hesi- tate to say any home is truly ice dam proof. It’s true that homes built after roof trusses became popular are far less likely to have ice dams than stick frame homes. There is simply more room in the roof system for insulation and ven- tilation, the two primary considerations when exploring ice dam issues on the standard home. A project we do quite frequently is shown in the photo below. We remove the roofing from the affected roof pitch, remove the roof decking, add high-performance spray foam urethane insulation and then re-roof using ice and water membrane to exceed Minnesota building code.

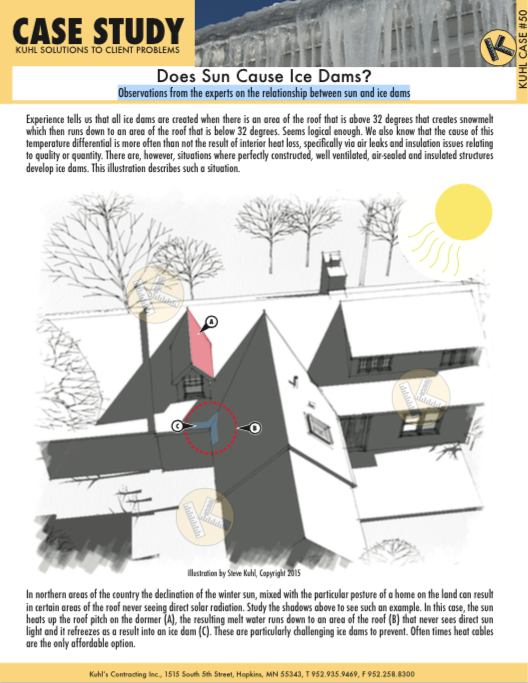

Observations from the experts on the relationship between sun and ice dams

Experience tells us that all ice dams are created when there is an area of the roof that is above 32 degrees that creates snowmelt which then runs down to an area of the roof that is below 32 degrees. Seems logical enough. We also know that the cause of this temperature differential is more often than not the result of interior heat loss, specifically via air leaks and insulation issues relating to quality or quantity. There are, however, situations where perfectly constructed, well ventilated, air-sealed and insulated structures develop ice dams. This illustration describes such a situation.

In northern areas of the country the declination of the winter sun, mixed with the particular posture of a home on the land can result in certain areas of the roof never seeing direct solar radiation. Study the shadows above to see such an example. In this case, the sun heats up the roof pitch on the dormer (A), the resulting melt water runs down to an area of the roof (B) that never sees direct sun light and it refreezes as a result into an ice dam (C). These are particularly challenging ice dams to prevent. Often times heat cables are the only affordable option.