News & Articles

Cedar roof types in Minneapolis

December 12th, 2014

by Aaron Fruit

In the past twenty five years I have inspected over 9000 cedar roofs in the Minneapolis-St.Paul area. That’s a lot of climbing. In that time I’ve seen just about every type of cedar roof imaginable as well as all manor of defect and curiosity imaginable. That timeframe has allowed me to observe a number of roofs over their entire lifespan, from install to death. In fact, I have relationships with dozens of cedar roofs that have spanned over two decades. Normally, that roof will belong to a few homeowners and when I am called to inspect, the new homeowner doesn’t usually know I have a history with their home. It’s always entertaining to explain that I’ve worked on their home over the past ten or fifteen years.

In the past twenty five years I have inspected over 9000 cedar roofs in the Minneapolis-St.Paul area. That’s a lot of climbing. In that time I’ve seen just about every type of cedar roof imaginable as well as all manor of defect and curiosity imaginable. That timeframe has allowed me to observe a number of roofs over their entire lifespan, from install to death. In fact, I have relationships with dozens of cedar roofs that have spanned over two decades. Normally, that roof will belong to a few homeowners and when I am called to inspect, the new homeowner doesn’t usually know I have a history with their home. It’s always entertaining to explain that I’ve worked on their home over the past ten or fifteen years.

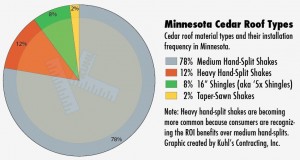

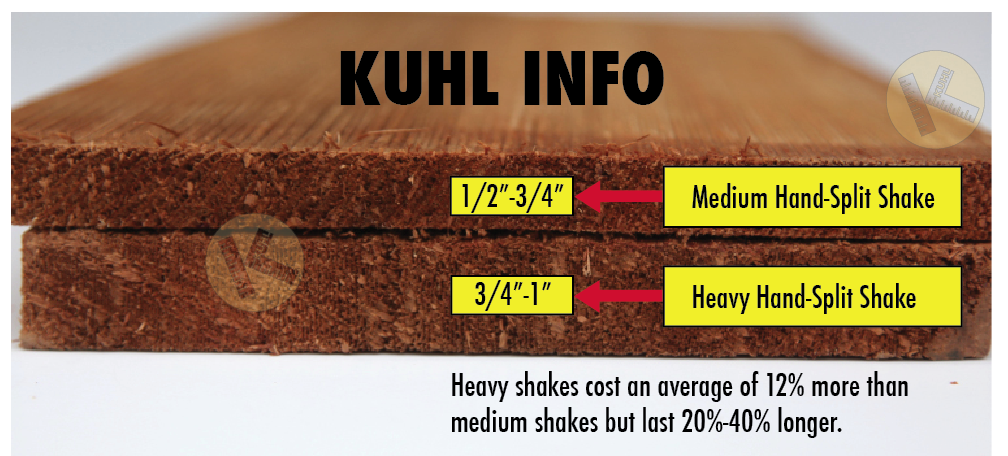

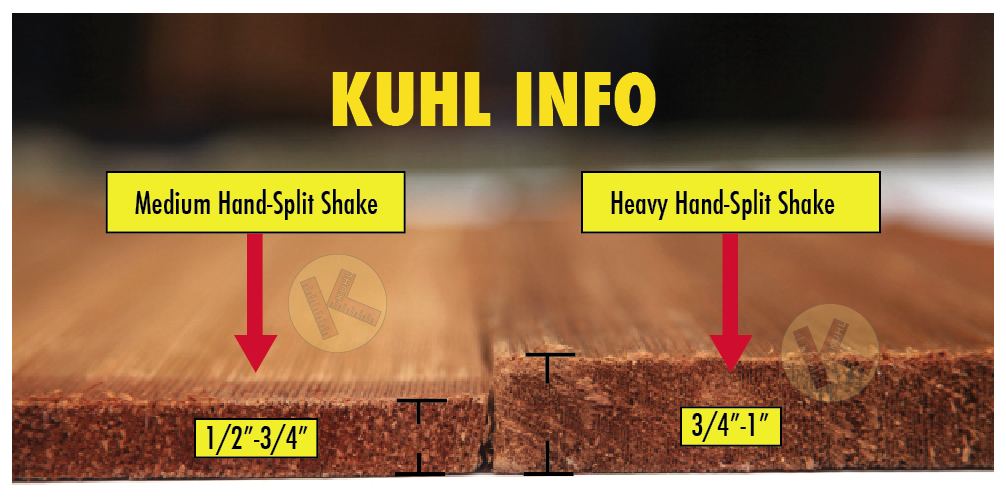

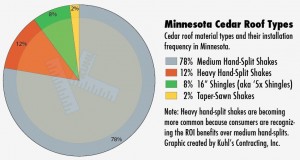

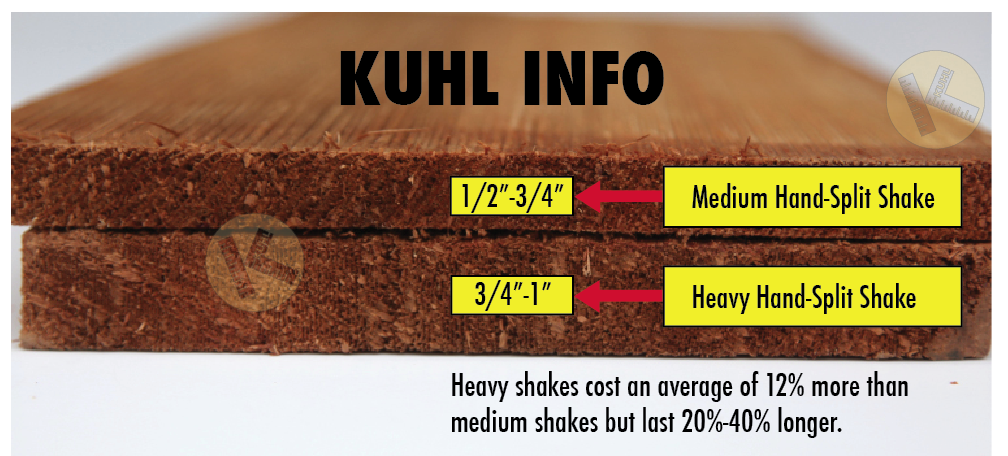

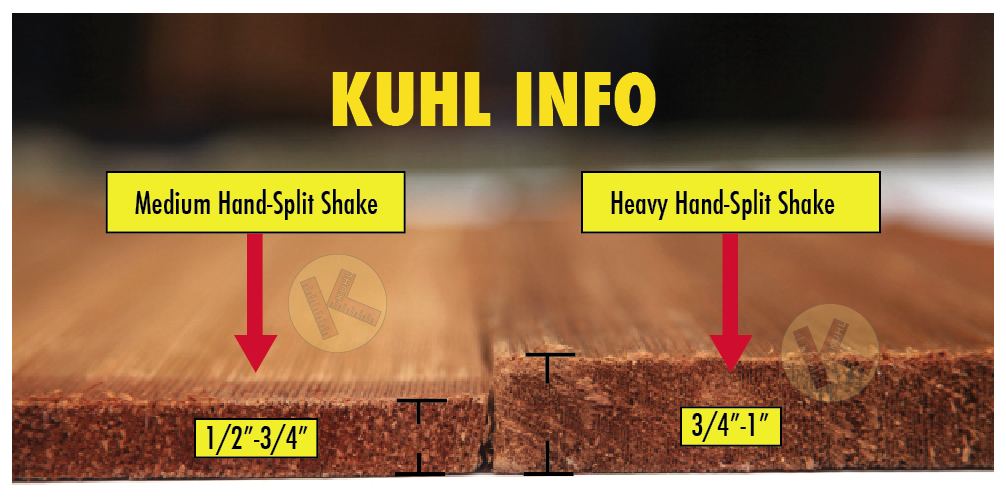

I was just asked in a seminar I was teaching on cedar roofs to home inspectors (https://www.facebook.com/MinnesotaHomeInspections) about the most common types of cedar roofs in Minneapolis and their relative market representation. Above is a graphic I created to communicate those statistics. In short, the 24″ medium hand-split cedar shake is still be far the most common material applied when it comes to wood roofs. That said, the people of Kuhl work hard every day to communicate the advantages of using heavy hand-split cedar shakes whenever possible. The fact is that it can last 30%-50% longer than medium hand-split shakes but it only costs roughly 11%-15% more. The ROI analysis on those numbers is pretty simple. At this point, the only clients of ours that choose medium shakes over heavies do so because they are about to sell their homes. People who are going to be there for more than five or ten years tend to see the wisdom in upgrading to heavy shakes.

Medium wood shake versus heavy wood shakes in Minneapolis

Heavy hand-split 24″ wood shake versus Medium hand-split 24″ wood shake in Minneapolis – Kuhl’s Contracting

Posted in Uncategorized

Roofing prices are on the rise in Minneapolis

October 1st, 2013

by Aaron Fruit

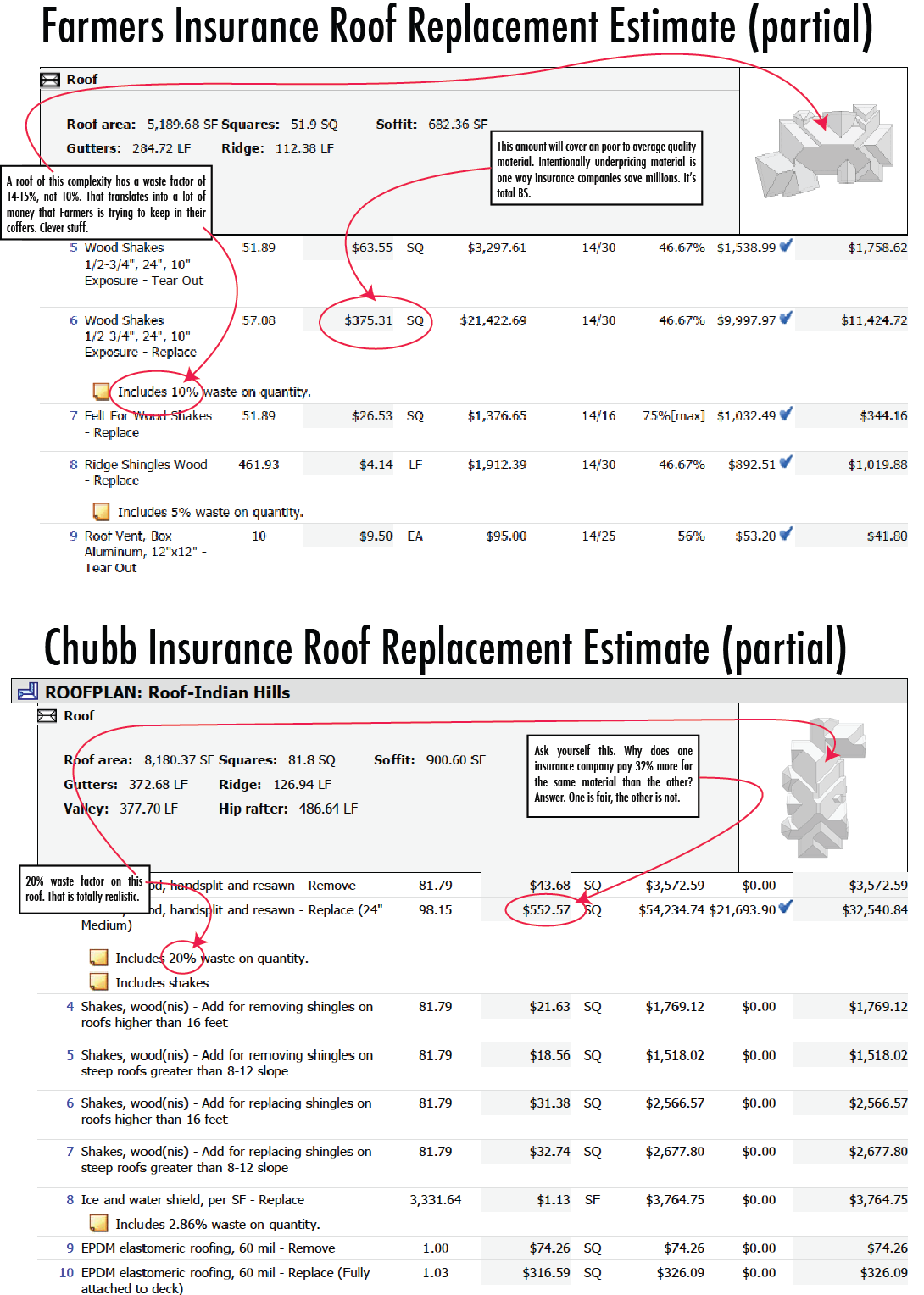

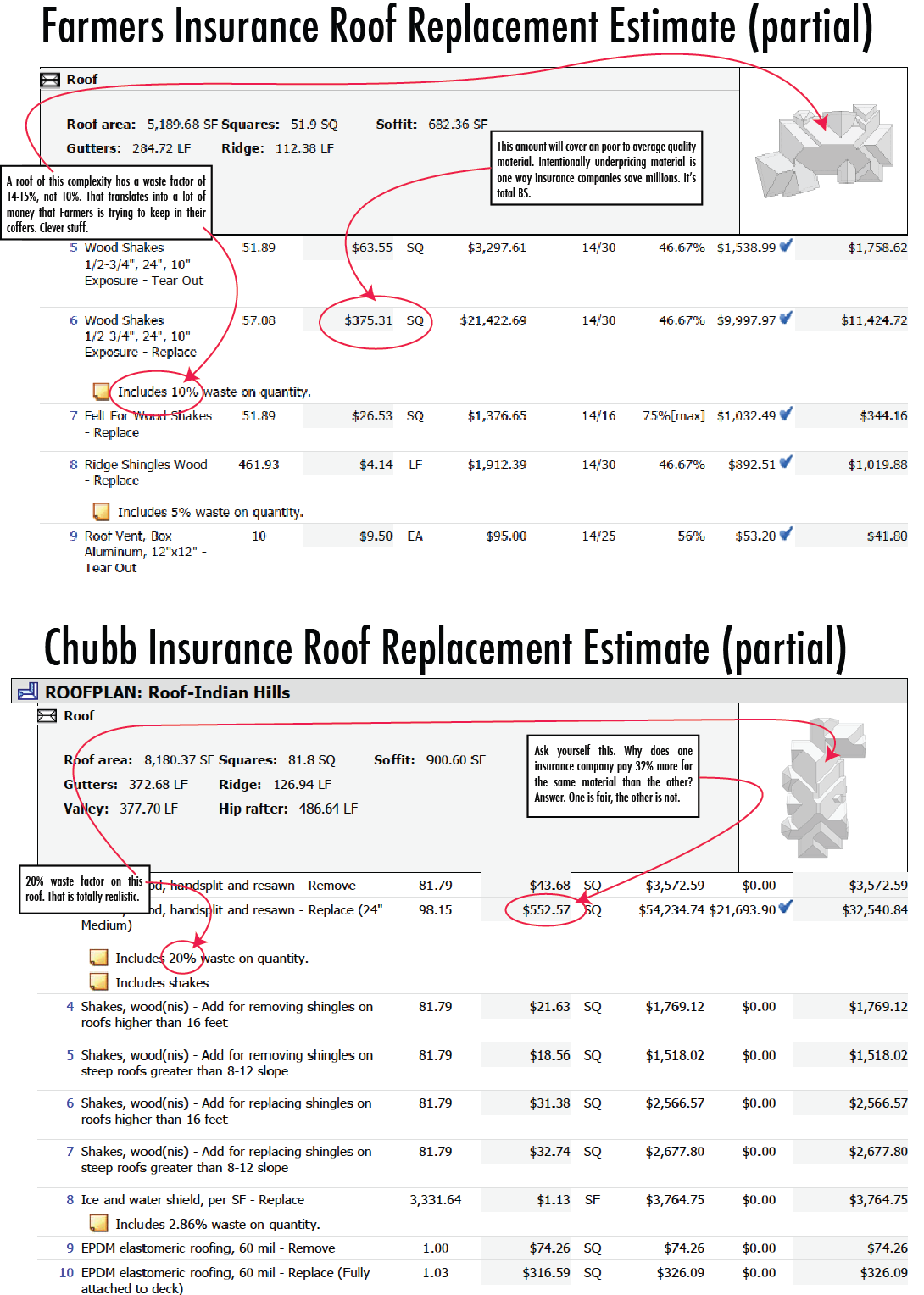

The primary challenge in working with insurance companies in terms of the replacement of roofs damaged by the August 6th hail storm isn’t so much in defining an accurate scope for the work but in getting paid fairly for that work. Insurance companies have an immense apparatus in place to depress pricing. It’s based on a proprietary software system called Xactimate and is one of the most effective tools insurance adjusters use to underpay claims. The fact is that right now a medium hand-split cedar shake roof costs $750 to $850 per square to install, including labor and materials. Variables such as roof complexity, steepness and height can push those numbers by 20% higher. Companies like American Family, Farmers and Allstate are offering $505 to $523 per square. We battle with these companies daily in trying to get them to understand the cost of cedar shake roofing. It’s often a fruitless effort because they simply refuse to pay market rate for this type of work. Just today I was told by an American Family adjuster that we should be able to buy shakes for $164 per square. I asked her if she would please share her source for such affordable product but she wouldn’t.

Here is a link to a current price list from one of our main suppliers in town. In fact, these guys sell wood to just about everyone and their numbers are as good as they get: Cedar roof wood roof material prices Minneapolis. We purchase a ton of wood. We are paying $200 per square for the cedar alone, some 18% higher than the aforementioned insurance companies want to pay. In the past six weeks we have seen the price of both labor and materials for cedar shake and shingle roofing increase by about 10% with an anticipated increase of an additional 10-15% by the spring of 2014.

While the price of materials is totally out of our control I’ve been asked a few times about why labor is increasing. After all, as the boss I’m the guy who controls what I pay my people, right? Yes and no. Here is what’s currently happening to my labor prices. Since the August 6th hail storm other companies have tried repeatedly to poach my guys out from under me by offering significantly higher wages. They literally walk onto our job sites and attempt to steal my guys! Ultimately I understand that this is just what happens when demand for skilled labor far exceeds the supply. The result is that my men are forced to ask me for a raise in order to stay put. I can’t blame my guys. We all have families to feed and we all need to do our best to earn a living. It’s basic economics. The net result is that the cost of qualified, experienced labor is skyrocketing here in the Twin Cities. The labor grab is happening across Minnesota as companies struggle to find qualified installers to get the work done. Excessive demand applied to limited supply equals increased prices. Econ 101. I think we need to send some insurance company storm adjusters to a class in basic economics.

Posted in Uncategorized

Insurance companies pay differently

August 25th, 2013

by Aaron Fruit

Okay, I should be moving on to part 2 of my last post “How to Fight Your Insurance Company” but this info just came in and I couldn’t resist.

Something that civilians don’t see in the midst of all of this hail storm madness is that the quality of the work that will be performed on their home is largely determined by two things. First, what insurance company is underwriting the home, and second, how aggressively their contractor pursues the insurance company on their claim.

As I mentioned in my last post, Chubb is a great insurance company. Expensive but great. Over the years I have seen dozens of situations where they do the right thing. When disaster strikes they pay on time and they pay enough for the client to hire a professional to put their home back together. And then there are the other guys. You know, the ones you see on TV a lot. On almost every claim we handle for clients using these McInsurance companies we end up having to push, argue and debate about both the scope of the loss and the cost to bring the home back up to speed. These companies consistently deny coverage and delay the process of discover and resolution in order to earn higher revenues. The good news is that if you have substantial holdings in insurance company stocks, you have seen your net worth increase handsomely. It’s bad news if you own a home and something happens that needs fixing professionally.

Over the past ten years I’ve noticed a clear trend in the way McInsurance firms handle property loss claims. They send out an adjuster that is marginally qualified to write an estimate, that is lacking in scope and realistic pricing and then submit it to the homeowner hoping they quietly accept it and go away. These guys are adept in the art of minimizing the ‘severity of loss’, to use industry speak. Many homeowners accept the estimate generated by their insurance company only to discover later that it’s woefully underpriced.

This is a clipping of two differently cedar roof replacement estimates from Farmers and Chubb from this week. Farmers pays about 32% less than Chubb to replace the exact same material. What does that mean to the average homeowner in the case of a cedar roof? In short, it means they get to hire one of their insurance company’s ‘preferred’ contractors who installs crappy wood using questionable labor. Side note: For those of you who are new to the world of insurance loss, if you are a Preferred Contractor for most insurance companies it means only that you have agreed to be underpaid, not that your work will stand the test of time. I tell everyone I care about to avoid preferred contractors as much as possible.

Whether you work with us or someone else with our chops, here is how the typical claims process goes down when you work with a pro: First step, your insurance adjuster visits, makes notes and generates a low-ball estimate to repair the damage (from hail, wind, fire, water, etc.). Step two, we take that estimate and examine it line by line to find then inevitable errors and omissions. Their estimate will usually be off the mark on the scope of the damage and always be low on the dollar amount it will take to make the repairs. Step three, we submit our estimate to your insurance company and begin a little back and forth discussion about your claim. In the case of a good insurance company they listen to reason quickly and we agree on a fair scope and price for the project. In the case of many McInsurance companies we have to push, prod and cajole until they have no choice but to relent and agree. Why? Because we argue for what is right. No games, no manipulation, no secrets. We just tell the truth about what needs to be done and it’s hard to argue with the truth. The final step is the easy part. We sign a contract with you for the work to be performed and it is scheduled and completed with the degree of professionalism people have come to expect from us.

Whether you work with us or someone else with our chops, here is how the typical claims process goes down when you work with a pro: First step, your insurance adjuster visits, makes notes and generates a low-ball estimate to repair the damage (from hail, wind, fire, water, etc.). Step two, we take that estimate and examine it line by line to find then inevitable errors and omissions. Their estimate will usually be off the mark on the scope of the damage and always be low on the dollar amount it will take to make the repairs. Step three, we submit our estimate to your insurance company and begin a little back and forth discussion about your claim. In the case of a good insurance company they listen to reason quickly and we agree on a fair scope and price for the project. In the case of many McInsurance companies we have to push, prod and cajole until they have no choice but to relent and agree. Why? Because we argue for what is right. No games, no manipulation, no secrets. We just tell the truth about what needs to be done and it’s hard to argue with the truth. The final step is the easy part. We sign a contract with you for the work to be performed and it is scheduled and completed with the degree of professionalism people have come to expect from us.

My advice is to find a company with the technical ability to repair your home to the highest standard and with the insurance process knowledge to make sure you insurance company is paying what they owe.

Finally, a parting question. Why is that that someone who insures through Chubb deserves a better roof than the person insuring through Farmers (or State Farm, Allstate, Travelers, SafeCo, etc.)? The answer of course is that everyone who pays to have their home insured should be treated with an equal amount of respect.

Posted in Uncategorized

How to fight your insurance company: Part One

August 25th, 2013

by Aaron Fruit

The recent storms that passed through the southwest communities of Minneapolis left a trail of damage and confusion (as well as an incredible bloom of storm chasers). Not surprisingly, the aftermath of that storm has been interesting for a veteran of the industry to observe. From the almost comical circus of door-knocking contractors to the parade of under-qualified insurance adjusters flown in from all over the country, clients with damaged homes have been witness to the truly ugly result of the 8-6-13 storm.

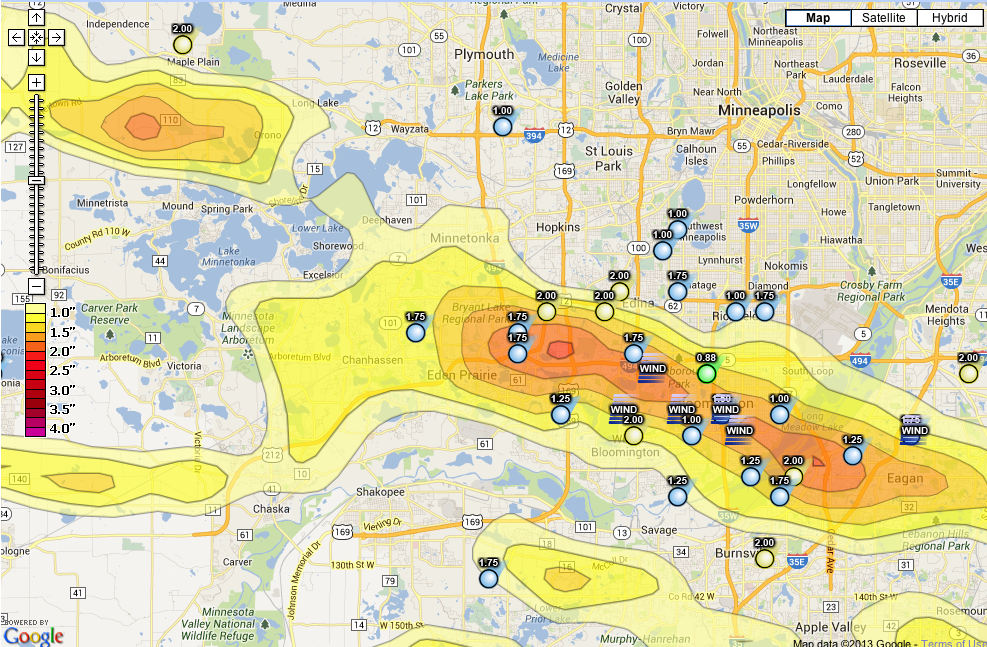

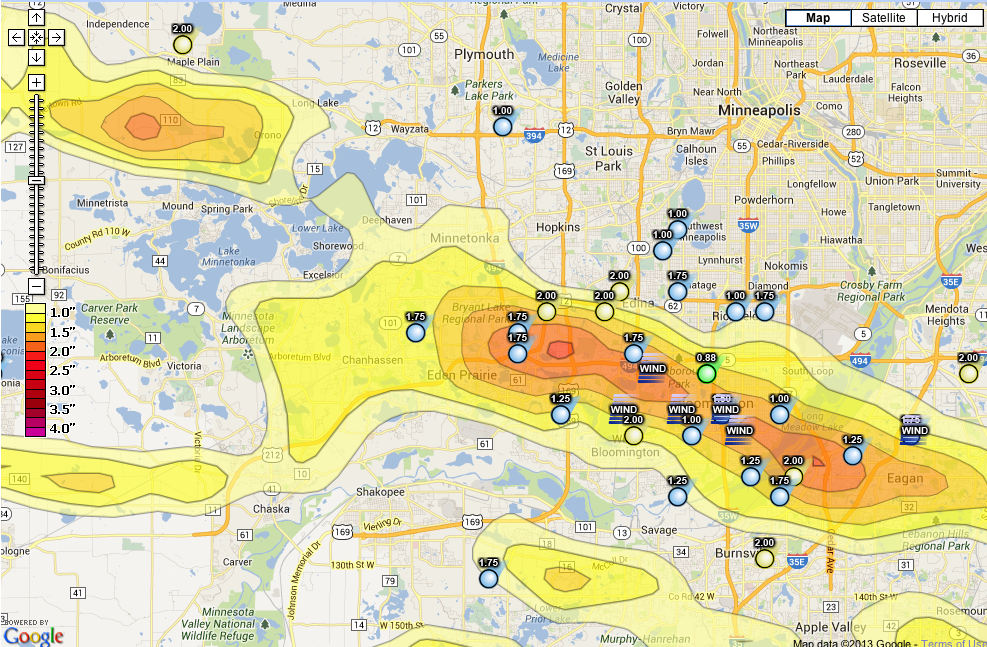

After having done good work for people for 25 years we don’t need to send guys to knock on doors (thank God). We’ve had a couple hundred former clients call us about inspecting their roofs after the storm pummeled their neighborhoods. Here is a hail map that you might find interesting.

Map showing hail storm path in Minneapolis

This map shows hail distribution and intensity in the southwest communities of Minneapolis. This is what storm chasers use to target neighborhoods. They can zoom in for a street by street view of hail size as soon as a couple hours after the storm passes through. Pretty impressive and pretty expensive. At about $300 a pop these maps are generated by a variety of ‘Hail Watch’ services found online. Our main use for these maps is to let the guy in Golden Valley know the hail he heard about on the news didn’t touch his house. It saves us a lot of time in doing pointless inspections. But I digress.

I plan on doing a comprehensive study of the events that have occurred since this storm that focuses on how different insurance companies apply different standards to assessing and paying for the damage done to properties. As I frequently tell clients, the likelihood of getting a fair settlement from an insurance company has more to do with who you insure with and who walks up your driveway the day of the inspection than the objective reality of what occurred at their home. It’s true. I’ll say it again. When it comes to storm damage claims, what happened to your home during the storm isn’t as important as who you insure with and who your adjuster is. For example, if you insure with Chubb, ACE or Fireman’s Fund, you will most likely be treated quite well. If you insure through anyone you have seen advertising on TV you may have a fight on your hands.

My study will include specific case studies with high resolution photos of damage to homes. The differences in what All State, Farmers, State Farm, Travelers, Liberty Mutual, et cetera, cover as opposed to the aforementioned ‘good guys’ is truly shocking. Perhaps even more disturbing is the difference from one claim to the next under the same company. I was on two All State claims today. One was denied and the other was approved. Both had virtually identical damage.

Another example, I was at two Liberty Mutual adjuster meetings last week in Edina. They were in essentially the same neighborhood and both had hand-split medium 24″ cedar shake roofs of similar age and condition. Both involved hired consultants on the roof while the adjuster stood on the ground. I stood there on the roof watching as both of these ‘experts’ made their determinations. One consultant went hail dent crazy (lucky client), circling with chalk dozens of damaged shakes while the other didn’t circle a single piece with comparable damage (unlucky client). The first client is getting a new $30,000+ roof, the latter is getting zero. Same insurance company, vastly different outcomes. It’s hard to watch. (I’m in the process of helping client #2 fight the findings…more on that later).

Here are photos of damaged cedar shakes from my Liberty Mutual clients. One is from the ‘approved for replacement’ roof and the other from the roof that was denied. The subjectivity involved in this process would be depressing to people if they understood how prevalent it is.

Surprise. This hail splatter is covered even though it should not have been.

Denied. This poor homeowner had an insurance adjuster apply arbitrary standards to his roof in Edina.

So, what can you do to increase the likelihood of being treated fairly after the storm? Number one, pay more for insurance and use Chubb, ACE or Fireman’s Fund. Number two, work with a company like ours to handle your claim from beginning to end. We employ a former insurance adjuster of 16 years on staff and if anyone knows how to get insurance companies to comply with reason it’s Pete.

More to follow soon on exactly how to best fight your insurance company if a claim doesn’t go your way.

Posted in Uncategorized

Squirrel Damaged Flashings

August 14th, 2013

by Aaron Fruit

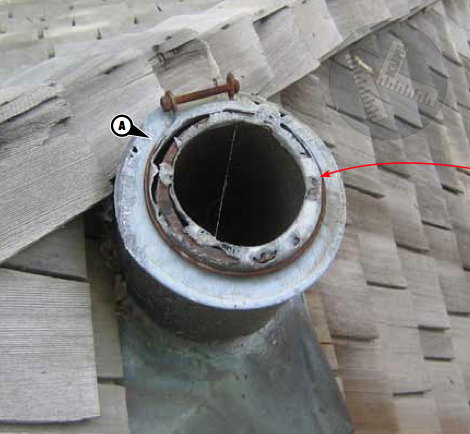

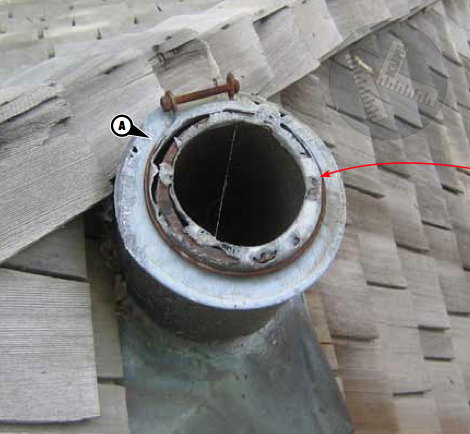

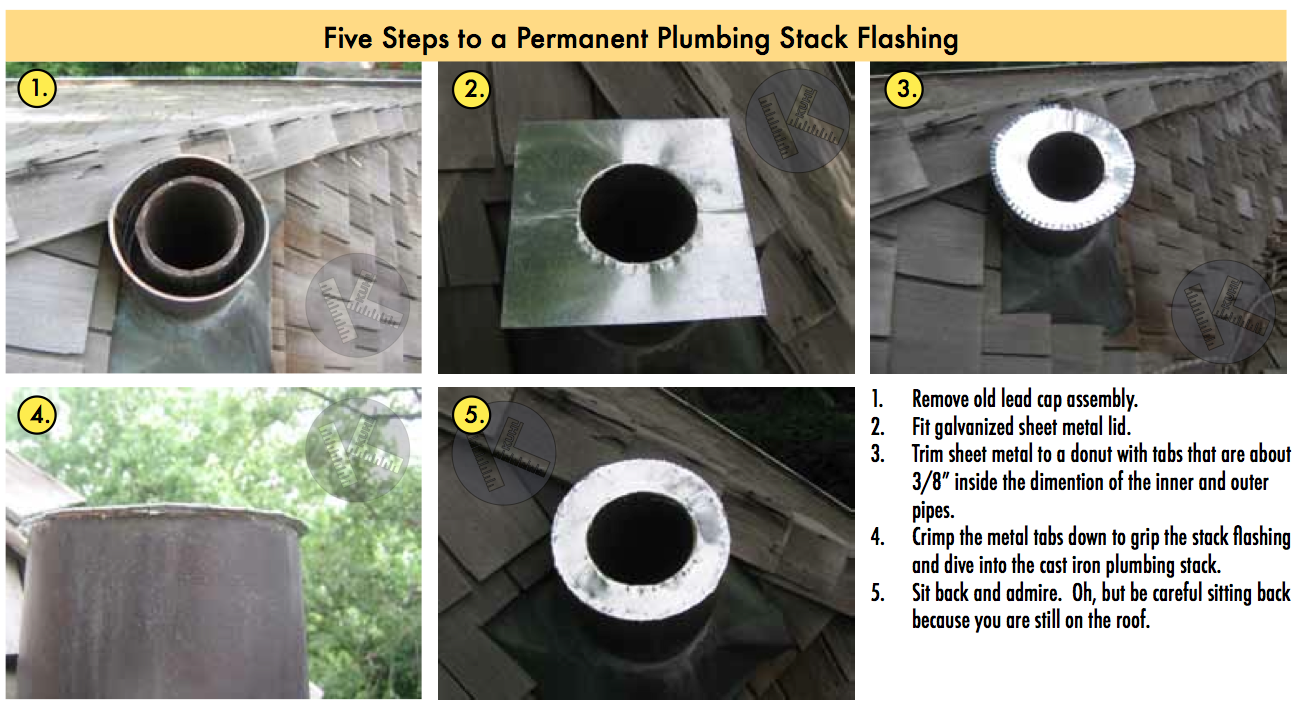

What is it with squirrels and roofs? They can’t seem to keep their teeth off them. We inspect hundreds of cedar roofs in the Twin Cities area each year. Time after time we find the same types of damage. Lead cap plumbing vent flashings such as the one here (A) are common targets of the squirrels zeal for chewing. Lead cap flashings are also commonly used on asphalt, tile and slate roofs with a similar outcome. If you look closely you can see all the teeth marks.

Minneapolis home damaged by squirrel

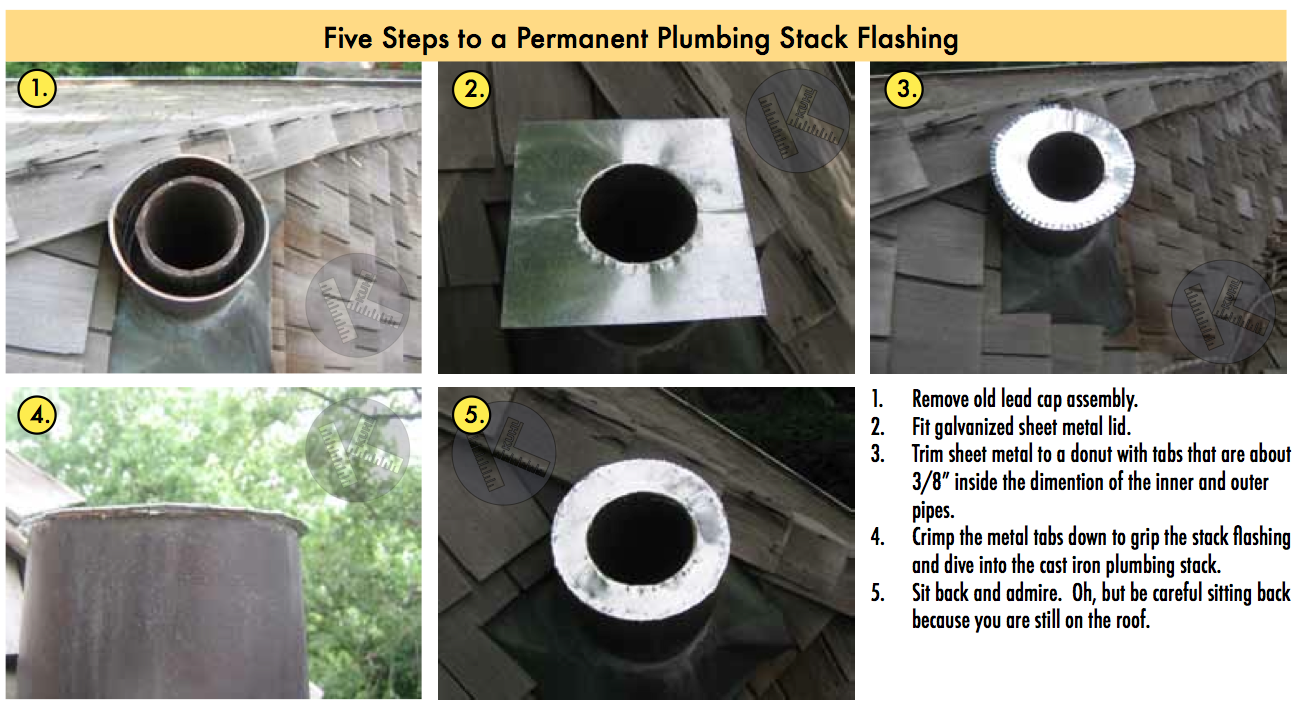

We have resolved this sort of squirrel damage in a few ways. The most obvious solution is to replace the entire lead cap with a new lead cap. This is the easiest solution but the problem is that once your neighborhood critters develop a taste for lead it seems that they just can’t help themselves. They

will contiue to come back and chew cap after cap. We came up with the below solution on one such roof. After being called out three times to fix the same leaking flashing we decided to employ a more permanent, albeit expensive, solution.

How to keep squirrels from damaging your plumbing flashing in Minneapolis

Go to our Case Studies to explore more animal damage.

Posted in Uncategorized

Cedar Roof vs. Asphalt Roof

February 20th, 2013

by Aaron Fruit

Kuhl’s Contracting specializes in the installation of cedar roofs and cedar roof restoration, so we know a lot of folks who own cedar roofs. When it comes time to replace the roof, it seems like we always get asked the following question: “Should I switch to an asphalt roof?? They are definitely less expensive. What are the benefits of a cedar roof?”

We are more than happy to provide them with asphalt roof pricing, but along with the prices for an asphalt roof, we also go over the following list of cedar roof benefits. Here are some things to consider prior to replacing a cedar roof with asphalt. Regardless of your decision, our hope is that this list will help to avoid the “Boy, I wish I would have known that” moment later on.

Cedar Roof Benefits: Cedar Roof vs. Asphalt Roof

1.) Cedar has higher impact (hail) rating than most asphalt shingles

According to the Cedar Shake and Shingle Bureau, “Certi-labelTM products have been tested to meet Class 3 and 4 impact resistance ratings.” Class 4 is as high as it gets. Asphalt roofs typically see more hail damage than cedar roofs.

2.) Cedar have a high wind resistance (wind) rating

According to the Cedar Shake and Shingle Bureau, the wind rating for cedar shakes and cedar shingles is as follows:

- Certigrade® shingles withstood wind speeds of 173 MPH

- Certi-Split® shakes withstood wind speeds of 245 MPH

Most Asphalt shingles max out around 130 MPH. Just for your reference, roofing materials are separated into classes depending on their wind resistance. Cedar is tops.

- Class A (for winds up to 60 mph)

- Class D (90 mph)

- Class F (110 mph)

- Class G (120 mph)

- and Class H (150 mph)

3.) Cedar has a higher insulation value (R-value) than asphalt shingles.

Tests show that a cedar roof has a much higher R-value than that of an asphalt roof. In fact, tests completed by the University of Texas show that the average attic space below a cedar roof is 26-28 degrees cooler than that of an attic space below an asphalt roof. Of course, this test was conducted during the summer months. (See notes from University of Texas (Arlington) study)

4.) A Cedar roof is thicker than an asphalt roof. This often causes problems and complications when switching from a cedar roof to an asphalt roof.

Meaning if replacing a cedar roof with asphalt, some of the existing flashings, trim, and roof accessories will not fit tightly any longer. If not corrected properly, this may cause problems with water infiltration and provide unwanted habitat for animals.

5.) A home with a cedar roof can fetch a higher resale value

A newer cedar roof can increase your home’s resale value. Something to ask your realtor if you are planning to sell in the near future.

6.) A cedar roof provides for more architectural character.

Cedar roofs have a very distinct look and most homeowners find them incredibly appealing and attractive.

7.) Cedar is a “green” material, it is a NON-petroleum based product and is a renewable resource.

Cedar is a natural material. It is harvested in a sustainable manner and is renewable. Cedar is also recyclable. Because cedar is natural, no two roofs are the same.

8.) Neighborhood continuity

Most cedar roofs are not alone. They are congregated in an area. You don’t want to the have the only house in your area with an asphalt roof. When an asphalt roof is surrounded by homes with cedar roofs, the asphalt often appears compromised or cheap.

9.) Cedar roofs have (4) layers of protection between the elements and the roof deck, which means, they are better at preventing ice dams.

With cedar shingles, there are (3) layers of material and one layer of underlayment. With cedar shakes, there are (2) layers of material, (1) layer of interlaced felt and (1) layer of underlayment. With an asphalt roof, there are only ever (2) layers of materials and one underlayment layer.

10.) Cedar roofs are easier to repair and match than asphalt roofs.

You never know if you are going to get an exact match when trying to color match asphalt shingles. Batch to batch, the asphalt shingles color pallets can change and often times, repairs are quite evident, never fully blending in to the surrounding roofing material. Cedar on the other hand, is natural, and fades in color over the course of a couple years. All cedar fades to a similar color with exposure to the elements. Therefore, it is much easier to repair small areas with cedar roofs, because you know you can get a color match.

11.) Cedar roofs are not always more expensive than asphalt

There are some types of asphalt shingles that can be just as expensive as cedar if not more expensive.

Posted in Uncategorized

Attic Frost: The Other…. Silent Killer

February 15th, 2013

by Aaron Fruit

If you haven’t taken a look in your attic space lately, it might be a good idea to take a quick glance around this winter.

Who goes in their attic space in the winter? Come to think of it, who ever goes in their attic space? It’s not usually the most comfortable atmosphere which explains why few of us venture beyond the attic access hatch.

These last few winters we’ve been getting more and more calls to repair “roof leaks”, “ceiling damage”, “skylight leaks”, and “leaks because of ice dams”. When we arrive at the home to check it out we have discovered there weren’t any issues with the roof. No bad flashings around the skylights or chimney and not enough snow and ice on the roof to be the culprit. So, what is causing all of these leaks during the winter if it isn’t rain, snow or ice? The one common denominator that we found was frost (or moisture) in the attic space. Most homeowners never look in their attic spaces, and if moisture is present, slowly but surely, it can cause damage without the homeowners knowing about it.

Signs of Frost

If it is present, frost is usually quite easy to spot in the attic space. Frost will form on the underside of the roof deck, along framing members and even on the topside of the insulation. But let’s say that it is a warm day and the frost has melted. What are you looking for? You’d be looking for wet/damp insulation, crusty or crisp insulation, delaminated plywood, signs of mold or mildew growth on the underside of the roof deck, rotten or discolored framing, unexplained staining on the ceilings of your rooms, or drips from lighting fixtures or other penetrations in the ceilings.

Common Causes of Attic Frost

In order to eliminate frost build up in the attic space, we have to understand what causes it in the first place. Frost in your attic space is a sign that warm, humid air is somehow getting into your attic space. Since our Minnesota winters are usually dry, the only other source of humid air is your living space. How does humid air get from our house and into the attic? Lots of ways, many of which are small is difficult to detect. Examples include improperly sealed attic hatches, gaps around pipes and penetrations that go from the living space up into the attic, recessed lights and more. As that warm, humid air gets into the attic space, it condenses on the roof decking, framing, and even on the insulation. When the temperatures dip below freezing, the condensation quickly turns to frost. See photos of what that looks like.

In no particular order, here are some common causes of frost build up in the attic space.

– #1: Warm Air Bypasses – gaps, cracks, holes where warm air is allowed to enter the attic space from below (electrical, plumbing, wall plates, etc). See photos below for several examples.

– Homeowner Usage – has the humidity too high in the house by (a) not running bathroom or kitchen fans, (b) HVAC controls set improperly, and/or (c) running portable humidifiers

– Lack of proper insulation in the attic space

– Poorly defined thermal barriers, confused attic spaces

– Lack of proper ventilation to your attic space

Solving the Frost/Moisture Issue

WARNING – DO NOT JUST ADD INSULATION. This will do nothing, and perhaps make your problem worse. There are a number of items that you need to take into consideration if you want to control the moisture levels in your attic space. You need to take a holistic approach to dealing with moisture. There is no one solution alone that will solve the issue. Depending on the house and the occupants, the scope of work usually involves some combination of the following:

Air Sealing: air sealing of the warm air bypasses, thus eliminating or minimizing the amount of humid air that can enter the attic space is a MUST.

Ventilation: assessing the ventilation of the attic space is also a MUST. If warm, humid air does get into the attic space, is there enough air flow to either carry it out or to help evaporate and get rid of the moisture.

Insulation: assess the amount of insulation in the attic space. Is it up to code, do you have enough of a thermal blanket? Usually, when air sealing, you disturb the existing insulation enough, that it makes sense to blow in additional insulation for R-value.

Humidity Control: some homeowner’s don’t want to hear this, but you need to monitor the indoor humidity levels.

Posted in Uncategorized

Versatility of Thermal Imaging: Finding Cat Pee

January 31st, 2013

by Aaron Fruit

Yesterday I was in a client’s home doing a routine thermal inspection when I started to notice wet spots all over the basement floor. I immediately thought they were leaks coming from plumbing in the ceiling. A quick thermal image of the ceiling ruled that out. After scratching my head for a bit I walked around a corner and saw the litter box, which looked like it hadn’t been used in months. It reminded me of this piece of classic literature. While the cat was scolded, I was dodging land mines and trying to finish my thermal inspection.

Cat pee on foor

Add it to the list of things you can do with a thermal imager. Not only can you find inefficiencies in your home’s thermal envelope, but you can also check to see if your baby needs a diaper change.

Thermal Imaging – because its a lot better than sniffing around the floor on your hands and knees.

Posted in Uncategorized

Ice Dam Leak in Minneapolis

December 18th, 2012

by Aaron Fruit

Ice dam causing leaking through ceiling in Edina home.

Ice dams cause leaks in Minneapolis homes but not usually until later in the ice dam season. I received a call earlier today from a client in Edina with water pouring through her ceiling. The water was coming through a smoke detector (B) and soaking her floor. One interesting but not entirely surprising thing was that the water affected a much larger area than was obvious from below (also showed at location C). Slight cracking in the door frame also indicated water problems (B).

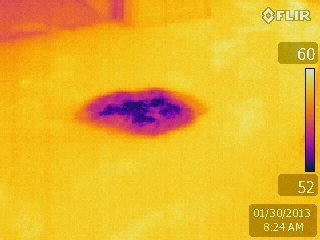

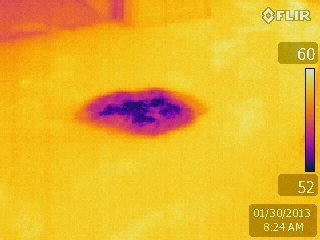

When I looked up I notice a ring of discoloration around the smoke detector (seen in photo, below). The thermal imager revealed a 6′ x 6′ area of wetness around the smoke detector. The client had a hard time understanding why the water had not shown in a larger area until I explained how her ceiling assembly worked. Because there was unconditioned space above the drywall there was also a code required vapor barrier, i.e, plastic sandwiched between the drywall and the ceiling framing. When the ice dam above caused water to back up and leak into the home it collected on top of the ceiling until it found the path of least resistance in the vapor barrier. In this case that was a smoke detector but it is often a light fixture, a vent or a seam in the plastic itself.

A quick look at the thermal image shows a large dark purple area (photo below, point B). This is wetness that has not yet manifested visually from below. It is damage nonetheless and should be repaired.

A quick look at the thermal image shows a large dark purple area (photo below, point B). This is wetness that has not yet manifested visually from below. It is damage nonetheless and should be repaired.

We take immense pride in being industry leaders in ice dam prevention, insulation and ice dam removal. There isn’t another ice dam removal company in town that has thermal imaging technology in-house or guys like Tom, who are certified geeks in all things relating to home performance technology. Here is an article Steve Kuhl published in the Journal of Light Construction on ice dams, if you feel like digging in to the topic deeper.

New insulation in Edina plus ice dam removal and ice dam prevention

Posted in Uncategorized

Cedar Roof Comparisons & Life Spans in Minneapolis

October 25th, 2012

by Aaron Fruit

How long will a cedar roof last in Minnesota? How long will a wood roof last in Minneapolis?

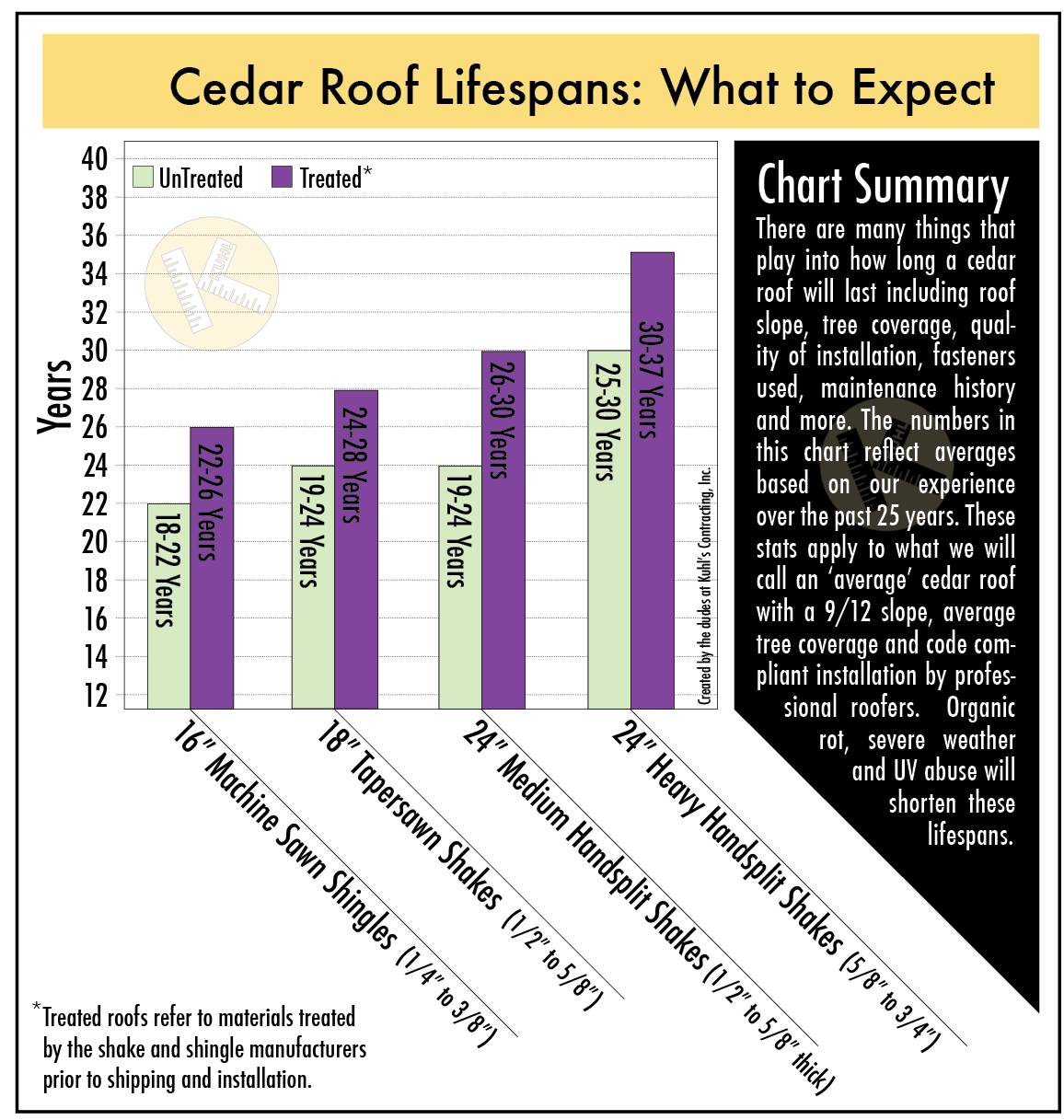

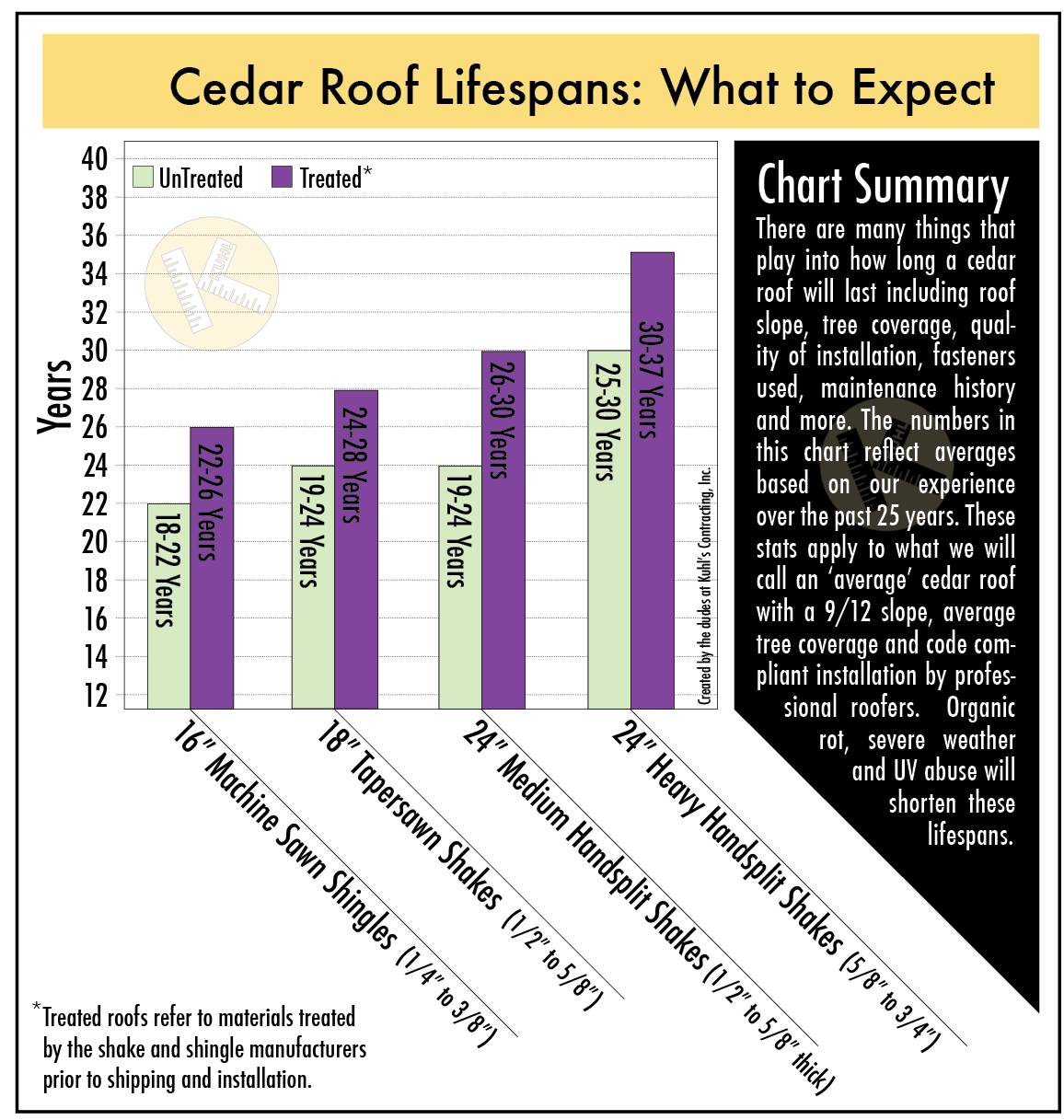

Understanding how long a cedar roof will last is one of the most important considerations in deciding which material to choose. Here is the skinny on the most common wood roof materials, their basic characteristics and expected lifespans in the Minneapolis area:

16” Machine Sawn Shingles (Life Span 17-21 Years)

Cedar shingles are used for both roof and side wall applications and offer a lighter, more refined appearance than hand-split shakes. Certain architectural home styles are more appropriate for Sawn Shingles which is the primary reason they are chosen in our experience. On average, this material ranges from 1/4” to 3/8” thick at the butt end and is installed with 5”courses. Expect to get between 17 and 21 years of service out of an unmaintained Cedar Shingle roof in Minnesota. Approximately 13% of Twin Cities cedar roofs are done in Machine Sawn Shingles.

18” Tapersawn Shakes (Life Span 19-24 Years)

The least common material we see in the Twin Cities, the Tapersawn Shake is essentially a hybrid between a common 24” shake and a 16” shingle. We frequently urge clients to consider using Tapersawn Shakes instead of 16” shingles because they offer the same clean, architectural appearance but are substantially thicker. Remember, when it comes to cedar roofing, thicker is better (all else held equal of course). On average, this material ranges from 5/8” to 3/4” thick at the butt end and is installed with 7”courses. Expect to get between 19 and 24 years of service out of an unmaintained Tapersawn Shake roof in Minnesota. Approximately 1% of Twin Cities cedar roofs are done in Tapersawn Shakes, but that percentage increases each year as more people become familiar with it.

24” Medium Hand-Split Shakes (Life Span 19-24 Years)

The most common cedar roofing material used in Minnesota, Medium Shakes are the workhorse of the industry. They are the go-to choice for home builders primarily because it is the most affordable wood roof one can find. The wide variations in quality from one load of Medium Shakes to the next also allows roofers to cut costs significantly, thus creating the perception of more value and increasing the likelihood Mediums will be selected (over tapersawn or hand-split heavy shakes, for example). On average, this material ranges from 1/2” to 5/8” thick at the butt end and is installed with 10”courses. Expect to get between 19 and 24 years of service out of an unmaintained Medium Shake roof in Minnesota. Approximately 70% of Twin Cities cedar roofs are done in Medium Shakes.

24” Heavy Hand-Split Shakes (Life Span 25-30 Years)

The second most common cedar roofing material used in Minnesota. We encourage our clients to consider Heavy Shakes whenever possible because they offer substantially more long-term performance for a small increase in cost up front. From the ground most people can not tell the difference between Medium and heavy Shakes other than a general increased perception of quality because they have more meat. On average, this material ranges from 3/4” to 7/8” thick at the butt end and is installed with 10”courses. Expect to get between 25 and 30 years of service out of an unmaintained Heavy Cedar Shake roof in Minnesota. Approximately 16% of Twin Cities cedar roofs are done in Heavy Hand-Split Shakes.

Posted in Uncategorized

In the past twenty five years I have inspected over 9000 cedar roofs in the Minneapolis-St.Paul area. That’s a lot of climbing. In that time I’ve seen just about every type of cedar roof imaginable as well as all manor of defect and curiosity imaginable. That timeframe has allowed me to observe a number of roofs over their entire lifespan, from install to death. In fact, I have relationships with dozens of cedar roofs that have spanned over two decades. Normally, that roof will belong to a few homeowners and when I am called to inspect, the new homeowner doesn’t usually know I have a history with their home. It’s always entertaining to explain that I’ve worked on their home over the past ten or fifteen years.

In the past twenty five years I have inspected over 9000 cedar roofs in the Minneapolis-St.Paul area. That’s a lot of climbing. In that time I’ve seen just about every type of cedar roof imaginable as well as all manor of defect and curiosity imaginable. That timeframe has allowed me to observe a number of roofs over their entire lifespan, from install to death. In fact, I have relationships with dozens of cedar roofs that have spanned over two decades. Normally, that roof will belong to a few homeowners and when I am called to inspect, the new homeowner doesn’t usually know I have a history with their home. It’s always entertaining to explain that I’ve worked on their home over the past ten or fifteen years.

A quick look at the thermal image shows a large dark purple area (photo below, point B). This is wetness that has not yet manifested visually from below. It is damage nonetheless and should be repaired.

A quick look at the thermal image shows a large dark purple area (photo below, point B). This is wetness that has not yet manifested visually from below. It is damage nonetheless and should be repaired.